At its core, the primary advantage of a U-shaped heating element is its unique design that allows for single-sided electrical connections. This configuration solves specific installation challenges where a straight rod cannot span the heating chamber or where access is limited to one side, such as in certain furnace designs or sealed radiant tube systems.

Choosing the right heating element requires understanding two distinct factors: the physical shape and the material. The key benefit of the U-shape is its installation flexibility, while the high-performance characteristics like extreme temperature resistance come from the Silicon Carbide (SiC) material it's made from.

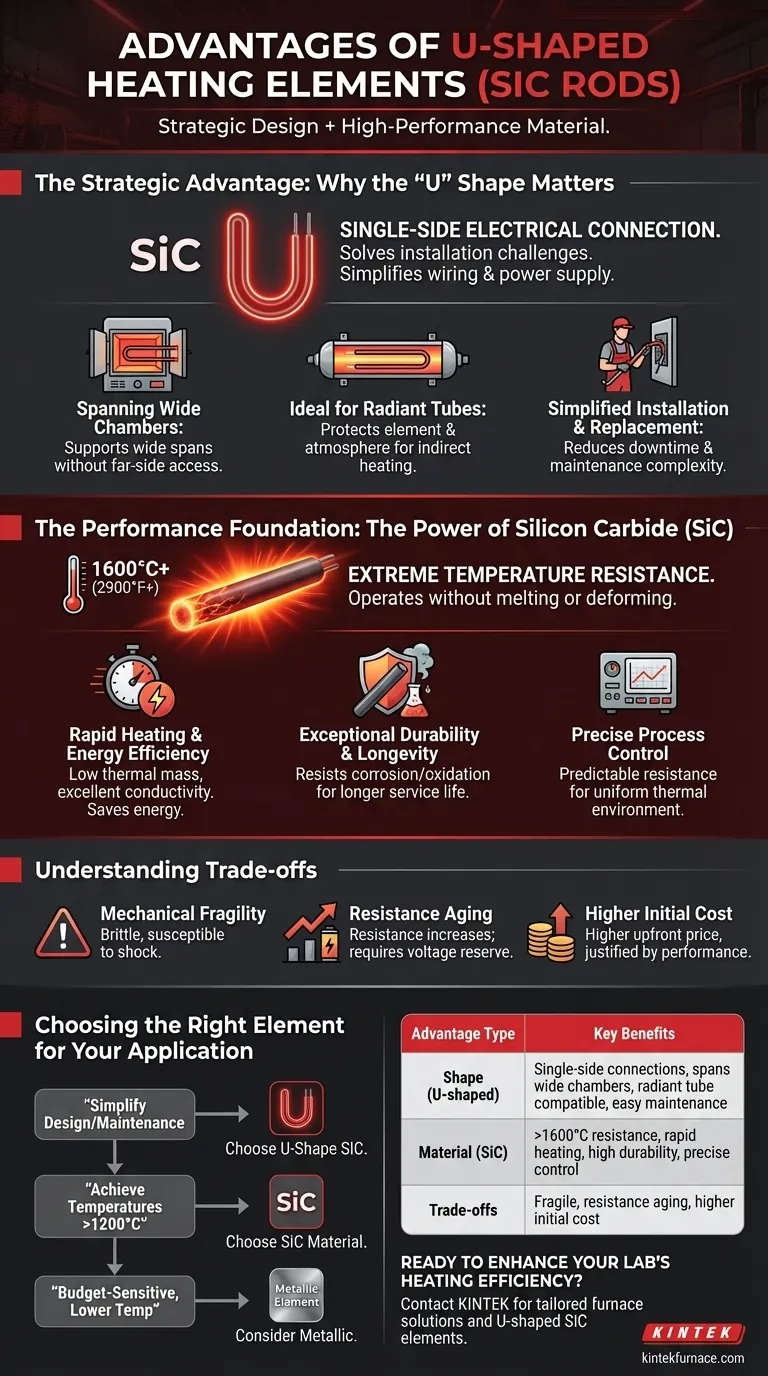

The Strategic Advantage: Why the "U" Shape Matters

The decision to use a U-shaped element is almost always driven by the physical constraints and design goals of the heating equipment. It is a solution to a specific set of engineering problems.

Single-Side Electrical Connection

The most significant benefit is that both electrical terminals are on the same side of the furnace. This simplifies wiring, reduces the complexity of the power supply system, and often makes the overall equipment footprint more compact.

Spanning Wide or Inaccessible Chambers

In large furnaces, using a single, long straight rod can be mechanically unstable. A U-shaped element, supported on one wall, can project heat deep into a chamber without requiring a second connection point on the far side, which may be difficult or impossible to access.

Ideal for Radiant Tube Systems

U-shaped elements are perfectly suited for radiant tubes. The element can be inserted into a sealed tube from one end, heating the tube which then radiates heat into the chamber. This protects the element from the furnace atmosphere and vice-versa, allowing for indirect heating.

Simplified Installation and Replacement

Because all connections are on one side, elements can be installed or replaced without having to completely cool down the furnace or access multiple sides of the equipment. This drastically reduces downtime and simplifies maintenance procedures.

The Performance Foundation: The Power of Silicon Carbide (SiC)

While the U-shape provides installation benefits, the reason these elements are used in demanding applications is the Silicon Carbide (SiC) ceramic material itself. These advantages are present regardless of the element's shape.

Extreme Temperature Resistance

SiC elements can operate at very high temperatures, often exceeding 1600°C (2900°F), without melting or deforming. This capability is essential for processes like sintering, melting, and heat treating specialized materials.

High Energy Efficiency and Rapid Heating

Due to its low thermal mass and excellent thermal conductivity at high temperatures, SiC heats up very quickly. This reduces process cycle times and saves energy, lowering overall operational costs.

Exceptional Durability and Longevity

Silicon Carbide is a hard, durable ceramic that resists corrosion and oxidation in many harsh industrial environments. This leads to a longer service life compared to many metallic heating elements, reducing replacement frequency.

Precise Process Control

The electrical resistance of SiC allows for precise temperature control through modern power controllers (like SCRs). This predictability is critical for applications requiring a stable and uniform thermal environment.

Understanding the Trade-offs

No solution is perfect. Being an effective advisor means acknowledging the limitations of SiC elements to prevent misapplication.

Mechanical Fragility

Like most ceramics, SiC elements are brittle. They are susceptible to damage from mechanical shock or impact, requiring careful handling during installation and operation.

Resistance Aging

Over their service life, SiC elements gradually increase in electrical resistance. Your power supply system must be designed with enough voltage reserve to compensate for this "aging" to maintain full power output over time.

Higher Initial Cost

Compared to common metallic elements like Kanthal (FeCrAl), SiC elements typically have a higher upfront purchase price. This cost is often justified by their longer life and higher temperature capabilities but must be factored into the project budget.

Choosing the Right Element for Your Application

Use this framework to align your choice with your primary engineering goal.

- If your primary focus is simplifying furnace design or maintenance: The U-shape is superior, as it allows for single-side connections that eliminate the need for wiring and access on both sides of the chamber.

- If your primary focus is achieving process temperatures above 1200°C (2200°F): The Silicon Carbide material is your key advantage, providing reliable heat where most metallic elements would fail.

- If your primary focus is budget-sensitivity for a lower-temperature application: A traditional metallic element may be more suitable, provided it meets your temperature and atmospheric requirements.

By separating the benefits of the element's shape from its material, you can make a precise and effective engineering decision.

Summary Table:

| Advantage Type | Key Benefits |

|---|---|

| Shape (U-shaped) | Single-side electrical connections, spans wide chambers, ideal for radiant tubes, simplified installation and replacement |

| Material (Silicon Carbide) | Extreme temperature resistance (>1600°C), high energy efficiency, rapid heating, exceptional durability, precise process control |

| Trade-offs | Mechanical fragility, resistance aging, higher initial cost |

Ready to enhance your lab's heating efficiency with tailored solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our U-shaped SiC heating elements can optimize your processes and deliver superior performance!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance