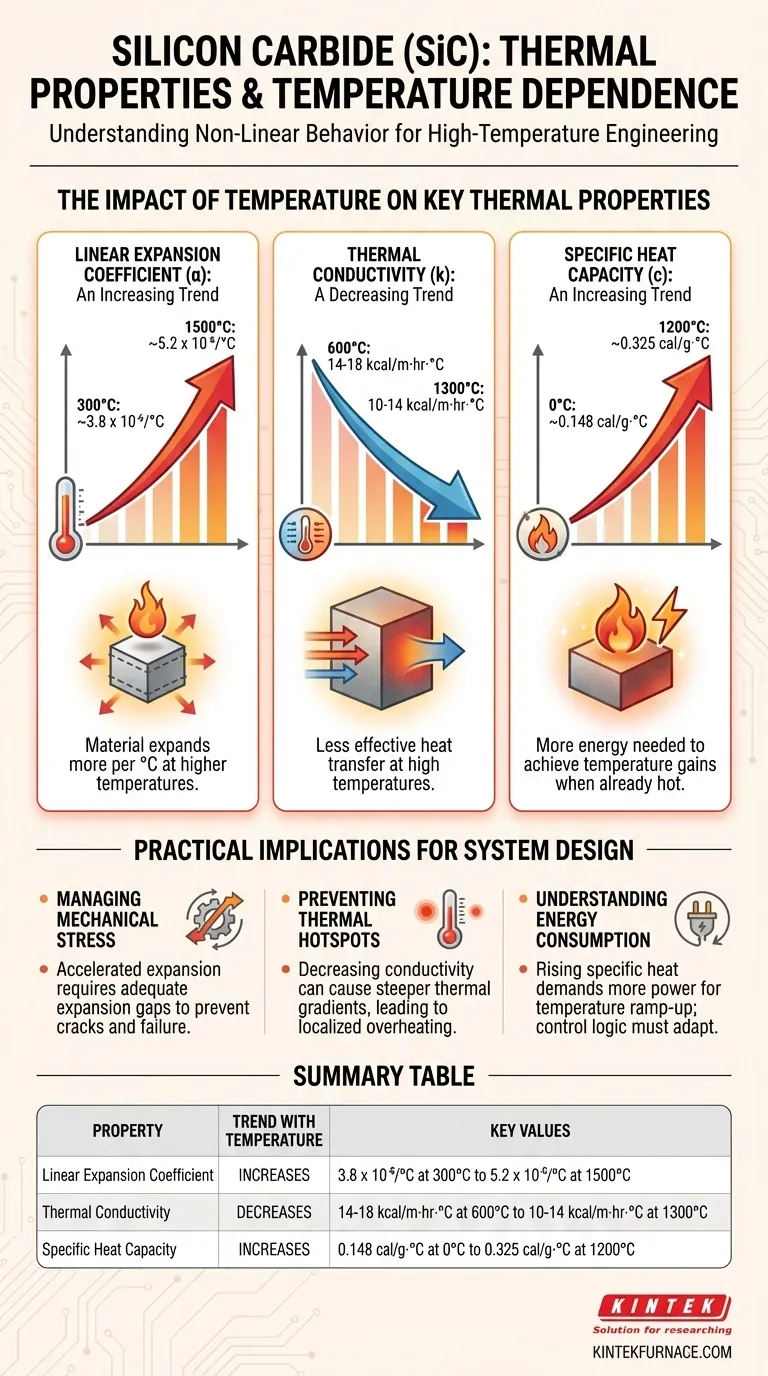

In short, the key thermal properties of silicon carbide are not static; they change predictably with temperature. As temperature rises, its linear expansion and specific heat both increase, while its thermal conductivity decreases. Understanding these dynamic behaviors is essential for any high-temperature engineering application.

The most critical insight for any designer or engineer is that Silicon Carbide's response to heat is non-linear. Accounting for these property changes is the difference between a system that is stable and efficient, and one that is prone to failure or unpredictable performance.

The Impact of Temperature on Key Thermal Properties

To design reliable systems using Silicon Carbide (SiC), especially for heating elements, you cannot use a single value for its thermal characteristics. You must understand how each property behaves across your intended operating range.

Linear Expansion Coefficient (α): An Increasing Trend

The linear expansion coefficient dictates how much the material expands when heated. For SiC, this rate of expansion increases as the material gets hotter.

For example, the coefficient rises from approximately 3.8 x 10⁻⁶/°C at 300°C to 5.2 x 10⁻⁶/°C at 1500°C. This means the material expands more for every degree of temperature change at higher temperatures than it does at lower ones.

Thermal Conductivity (k): A Decreasing Trend

Thermal conductivity measures how effectively a material transfers heat. Counterintuitively, SiC becomes a less effective heat conductor as its temperature rises.

At 600°C, its conductivity is in the range of 14-18 kcal/m·hr·°C. By 1300°C, this value drops significantly to 10-14 kcal/m·hr·°C. This decreasing conductivity is a critical factor in heat distribution calculations.

Specific Heat Capacity (c): An Increasing Trend

Specific heat capacity is the amount of energy required to raise the temperature of a given mass of material by one degree. For SiC, the specific heat increases with temperature.

It takes approximately 0.148 cal/g·°C to heat SiC at 0°C, but that requirement more than doubles to 0.325 cal/g·°C at 1200°C. This means more energy is needed to achieve temperature gains when the element is already hot.

Practical Implications for System Design

These changing properties have direct consequences on the mechanical and thermal performance of any system using SiC components. Ignoring them can lead to critical design flaws.

Managing Mechanical Stress

The increasing coefficient of thermal expansion is a major consideration for mechanical design. As the element heats up, its accelerated expansion must be accommodated by the mounting system to prevent the buildup of mechanical stress, which can lead to cracks and premature failure.

Preventing Thermal Hotspots

Because thermal conductivity decreases at high temperatures, heat does not dissipate as readily from the hottest parts of the element. This can create steeper temperature gradients, potentially leading to "hotspots" that can accelerate material aging or cause localized overheating.

Understanding Energy Consumption and Control

The combination of rising specific heat and changing electrical resistivity (a property not discussed in detail here but related) impacts control systems. The heater will require more power to raise its temperature at the higher end of its range, and its electrical properties will change simultaneously, a factor that must be included in the power controller's logic for stable operation.

Key Considerations for Your Application

To apply this knowledge effectively, focus on the most critical parameter for your specific goal.

- If your primary focus is mechanical stability: You must design fixtures with adequate expansion gaps that account for the non-linear increase in thermal expansion at your maximum operating temperature.

- If your primary focus is uniform heating: You must consider that SiC's decreasing thermal conductivity at high temperatures can create temperature gradients across the element and the workpiece.

- If your primary focus is energy efficiency and control: You must factor in the rising specific heat, as more energy will be required to raise the temperature at higher operating points, affecting both ramp-up times and overall power consumption.

Mastering how these properties interact is fundamental to engineering robust and predictable high-temperature systems with Silicon Carbide.

Summary Table:

| Property | Trend with Temperature | Key Values |

|---|---|---|

| Linear Expansion Coefficient | Increases | 3.8 x 10⁻⁶/°C at 300°C to 5.2 x 10⁻⁶/°C at 1500°C |

| Thermal Conductivity | Decreases | 14-18 kcal/m·hr·°C at 600°C to 10-14 kcal/m·hr·°C at 1300°C |

| Specific Heat Capacity | Increases | 0.148 cal/g·°C at 0°C to 0.325 cal/g·°C at 1200°C |

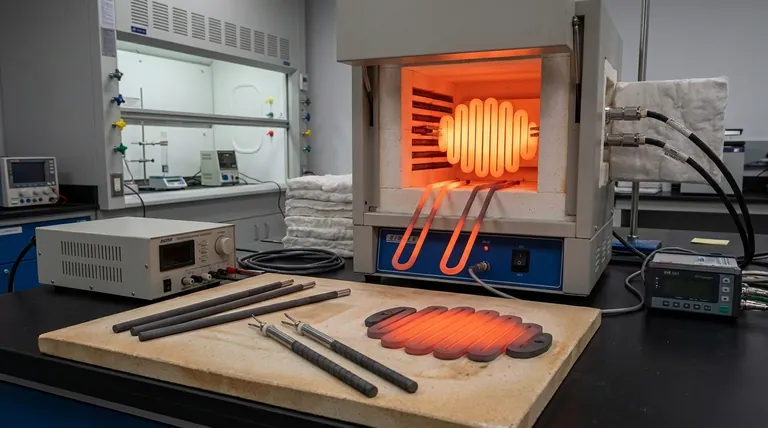

Optimize your high-temperature systems with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored silicon carbide heating elements and more, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can support your project with durable, high-performance thermal solutions!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan