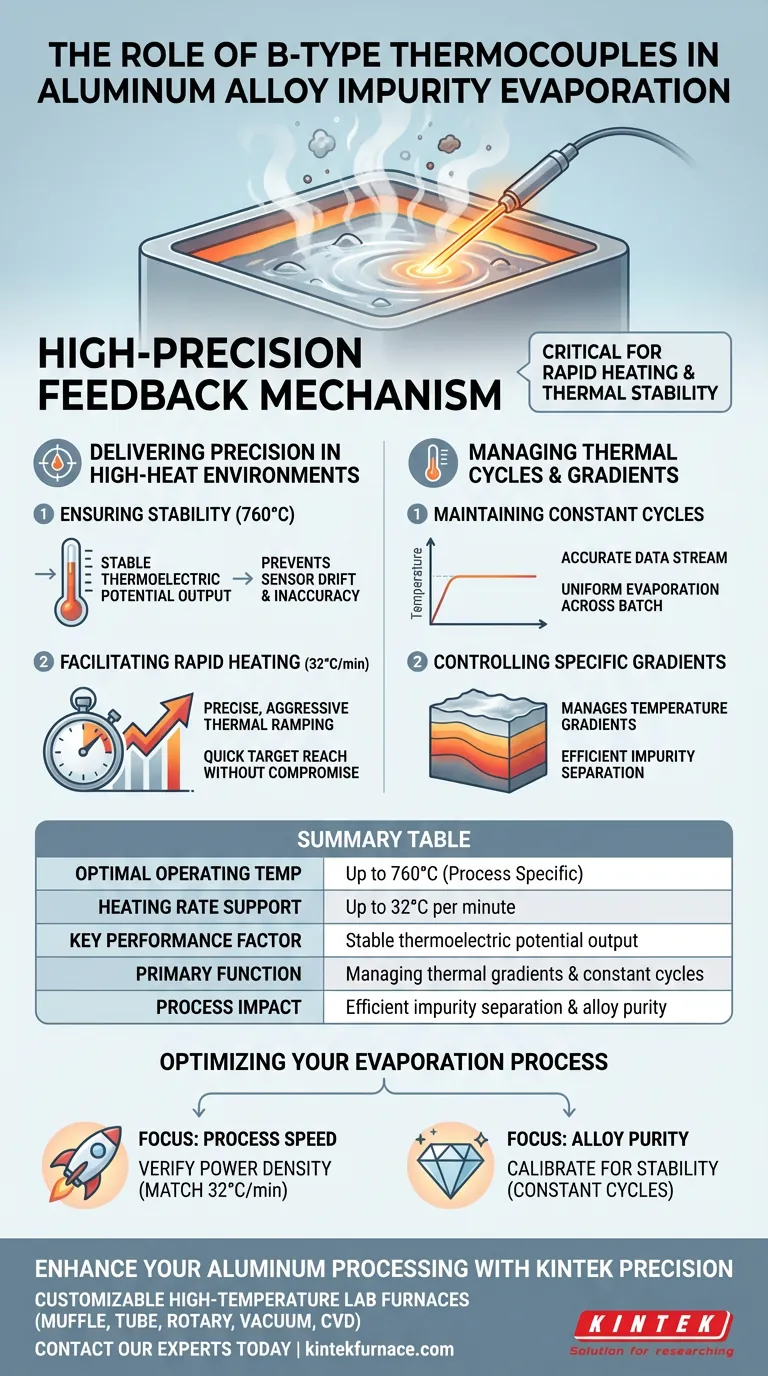

The B-type thermocouple acts as the high-precision feedback mechanism required to control rapid heating and thermal stability during the processing of liquid aluminum alloys. It specifically enables the management of critical temperature gradients at operational temperatures reaching 760 degrees Celsius.

In aluminum alloy impurity evaporation, success depends on adhering to strict thermal profiles. The B-type thermocouple provides the stable thermoelectric potential output necessary to drive precise heating rates and maintain the constant temperature cycles required for effective impurity separation.

Delivering Precision in High-Heat Environments

Ensuring Stability at Elevated Temperatures

Processing liquid aluminum alloys requires sustained operations at high temperatures, often reaching 760 degrees Celsius.

At this specific thermal range, the B-type thermocouple is selected because it provides a highly stable thermoelectric potential output. This stability is crucial for preventing sensor drift, which could lead to inaccurate readings and compromised alloy quality.

Facilitating Rapid Heating Rates

Efficiency in impurity evaporation often dictates a need for aggressive thermal ramping.

The B-type thermocouple allows temperature controllers to execute precise, rapid heating rates, such as 32 degrees Celsius per minute. This capability ensures the material reaches the target temperature quickly without sacrificing control or safety.

Managing Thermal Cycles and Gradients

Maintaining Constant Temperature Cycles

Once the target temperature is reached, the process often requires holding the alloy at a constant heat for a specific duration.

The B-type sensor provides the accurate data stream necessary for controllers to maintain these constant temperature cycles. This ensures that the evaporation process occurs uniformly across the batch.

Controlling Specific Temperature Gradients

The evaporation of impurities is physically driven by specific temperature gradients within the melt.

By providing high-precision feedback, the B-type thermocouple enables the system to manage these gradients effectively. This level of control is essential for ensuring that impurities are separated efficiently from the aluminum alloy.

Understanding Operational Requirements

Dependence on Controller Capability

While the B-type thermocouple provides precise data, it is only one part of the control loop.

To achieve a heating rate of 32 degrees Celsius per minute, the temperature controller and heating elements must be robust enough to act on the sensor's feedback immediately. Using a high-precision sensor with an inadequate control system will result in performance bottlenecks.

Optimizing Your Evaporation Process

To fully leverage the capabilities of a B-type thermocouple in your aluminum processing, align your system configuration with your specific goals:

- If your primary focus is process speed: Verify that your heating elements have the power density to match the sensor's tracking capability of 32 degrees Celsius per minute.

- If your primary focus is alloy purity: Calibrate your temperature controller to prioritize the stability of the constant temperature cycles provided by the sensor's output.

Precise thermal monitoring is the foundational step in transforming raw aluminum melt into a high-purity alloy.

Summary Table:

| Feature | Specification/Benefit |

|---|---|

| Optimal Operating Temp | Up to 760°C (Process Specific) |

| Heating Rate Support | Up to 32°C per minute |

| Key Performance Factor | Stable thermoelectric potential output |

| Primary Function | Managing thermal gradients & constant cycles |

| Process Impact | Efficient impurity separation & alloy purity |

Enhance Your Aluminum Processing with KINTEK Precision

Don't let sensor drift or thermal instability compromise your material quality. KINTEK provides industry-leading thermal solutions backed by expert R&D and world-class manufacturing. Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature lab furnaces are fully customizable to meet your specific temperature gradient and heating rate requirements.

Ready to optimize your evaporation process? Contact our experts today to discover how our high-precision equipment can deliver the stability and control your laboratory demands.

Visual Guide

References

- Aleksandar M. Mitrašinović, Milinko Radosavljević. Modeling of Impurities Evaporation Reaction Order in Aluminum Alloys by the Parametric Fitting of the Logistic Function. DOI: 10.3390/ma17030728

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the common types and corresponding working temperatures for MoSi2 heating elements? Choose the Right Element for Your Process

- What types of joints are recommended for connecting heating element sections? Choose Welded Joints for Reliability

- What are the advantages of Nickel-Chrome (NiCr) alloys for heating elements? Discover High-Temp Durability & Efficiency

- What are the primary benefits of quartz tubes in high-temperature applications? Achieve Precision and Purity in Extreme Heat

- What are the typical application temperatures for molybdenum disilicide (MoSi2) heating elements? Master High-Temp Performance

- What are the main advantages of ceramic heating elements over metal alternatives? Boost Efficiency and Durability

- Why is the placement of precision thermocouples at the base of the quartz crucible critical in InSe crystal growth?

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer