For connecting heating element sections, welded joints are the superior and most reliable method. A properly executed weld creates a single, continuous metallurgical bond that is electrically and mechanically indistinguishable from the parent material. While pressed or pressure joints can be used, they introduce significant risks of failure over time and require extensive validation to be considered safe.

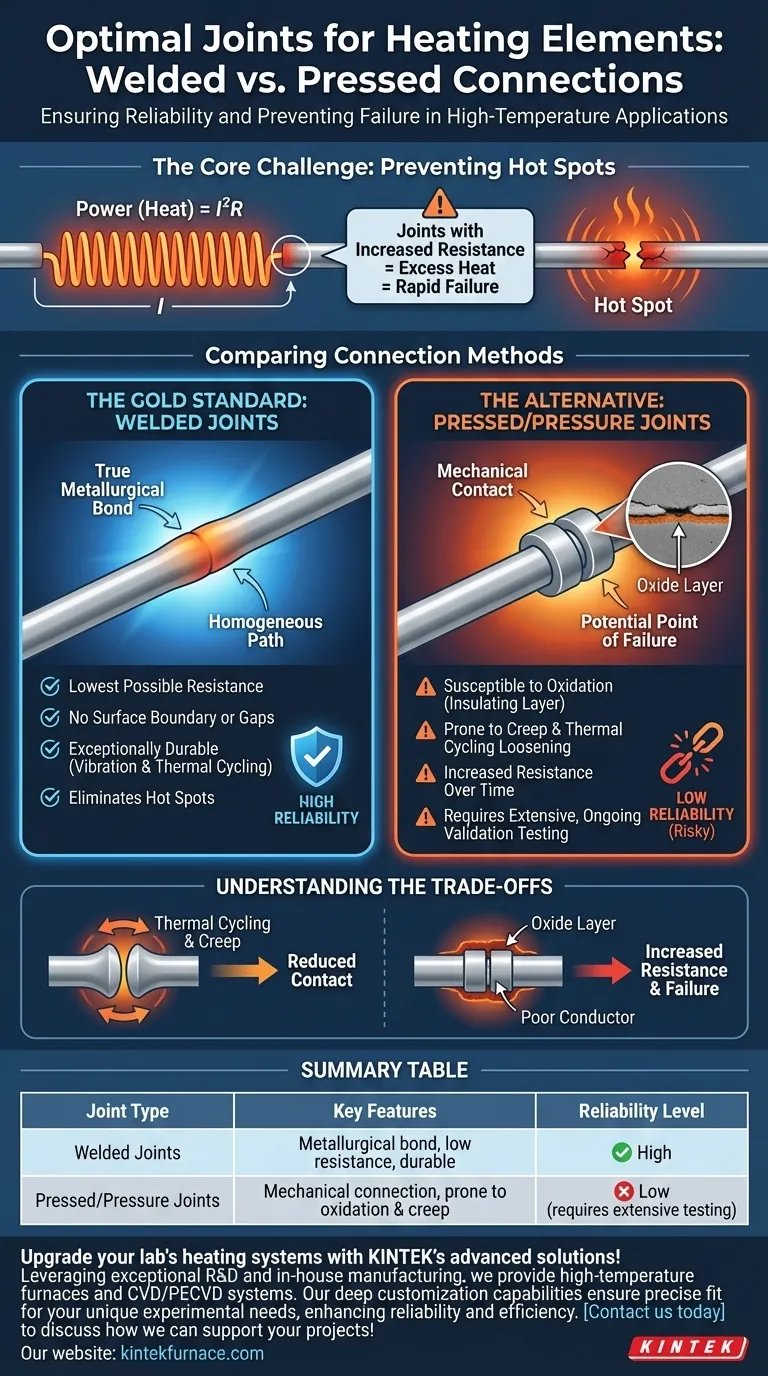

The core challenge in joining heating elements is not simply making an electrical connection, but preventing that connection from becoming a point of failure. Any joint that adds electrical resistance will generate excess heat, leading to rapid degradation and burnout.

Why Joint Integrity is Critical for Heating Elements

To select the right joint, you must first understand the physics that govern heating element failure. The joint is almost always the weakest link in the system.

The Physics of Failure: Resistance and Hot Spots

Every conductor, including a heating element, generates heat according to the formula Power (Heat) = I²R (Current squared times Resistance). The element is designed to have a specific, uniform resistance along its length to produce consistent heat.

A poor-quality joint introduces a small point of much higher resistance. Even a fractional increase in resistance at the joint will cause that specific spot to become significantly hotter than the rest of the element. This "hot spot" is the starting point for catastrophic failure.

The Goal: A Homogeneous Electrical Path

The ideal joint has the exact same electrical resistance and mechanical properties as the element wire itself. It should not be a separate component but an invisible, seamless transition.

Achieving this ensures uniform heating, predictable performance, and maximum operational life. The closer a joint comes to this ideal, the more reliable it will be.

Comparing Connection Methods

The choice between welding and mechanical pressing comes down to a choice between creating a truly homogeneous path or merely managing a potential point of failure.

The Gold Standard: Welded Joints

A welded joint is the only method that achieves a true metallurgical bond. The two pieces of metal are fused into one, eliminating any physical gap or surface boundary between them.

This results in the lowest possible joint resistance, virtually identical to the parent material. Consequently, it does not create a hot spot and is exceptionally durable against vibration and the stress of repeated thermal cycling.

The Alternative: Pressed or Pressure Joints

Pressed or pressure joints, such as crimps or bolted clamps, rely on mechanical force to press two surfaces together. The electrical current must flow across this surface boundary.

While they may perform adequately when new, they are inherently susceptible to degradation over time. The reference to "thoroughly tested" is a critical warning about their long-term instability.

Understanding the Trade-offs and Risks

Opting for a mechanical joint introduces failure modes that are simply not present with a properly welded connection. Understanding these risks is essential for any high-reliability application.

The Inevitable Risk of Oxidation

At operating temperature, the metal surfaces inside a pressure joint are exposed to oxygen. This causes an oxide layer to form. Most metal oxides are poor electrical conductors or even insulators.

As this insulating layer builds up, the joint's resistance increases, creating a hot spot that accelerates further oxidation. This vicious cycle is a primary cause of mechanical joint failure in heating applications.

The Danger of Thermal Cycling and Creep

As the element heats and cools, the metals expand and contract. This constant movement, known as thermal cycling, can gradually loosen a mechanical joint, reducing the clamping pressure.

Furthermore, under constant pressure at high temperatures, metal can slowly deform in a process called creep. Both effects lead to reduced contact, higher resistance, and eventual failure.

The Burden of "Thorough Testing"

The mandate to "thoroughly test" pressure joints is not a trivial matter. It requires a rigorous validation program that simulates the product's entire expected lifetime under worst-case conditions.

This involves extensive thermal cycling, vibration testing, and monitoring the joint's resistance to ensure it remains stable. The cost and time required for this validation can often outweigh the initial manufacturing convenience of using a pressure joint.

Making the Right Choice for Your Application

Your decision must be driven by the required level of reliability and safety for your product.

- If your primary focus is maximum reliability, safety, and product longevity: Use welded joints. This is the only method that effectively eliminates the joint as a primary failure point.

- If you are considering pressed joints due to manufacturing constraints: You must commit to a rigorous, expensive, and ongoing testing program to prove the joint will not fail prematurely in the field.

Ultimately, engineering a durable heating element means minimizing all potential points of failure, and the most effective way to secure a connection is to weld it.

Summary Table:

| Joint Type | Key Features | Reliability Level |

|---|---|---|

| Welded Joints | Metallurgical bond, low resistance, durable | High |

| Pressed/Pressure Joints | Mechanical connection, prone to oxidation and creep | Low (requires extensive testing) |

Upgrade your lab's heating systems with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise fit for your unique experimental needs, enhancing reliability and efficiency. Contact us today to discuss how we can support your projects!

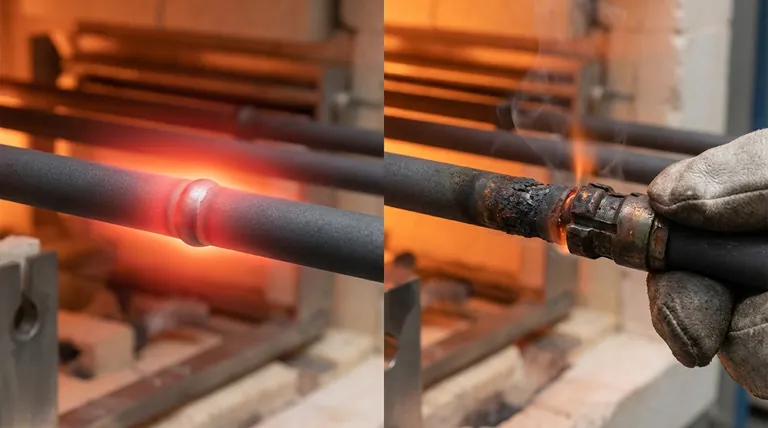

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance