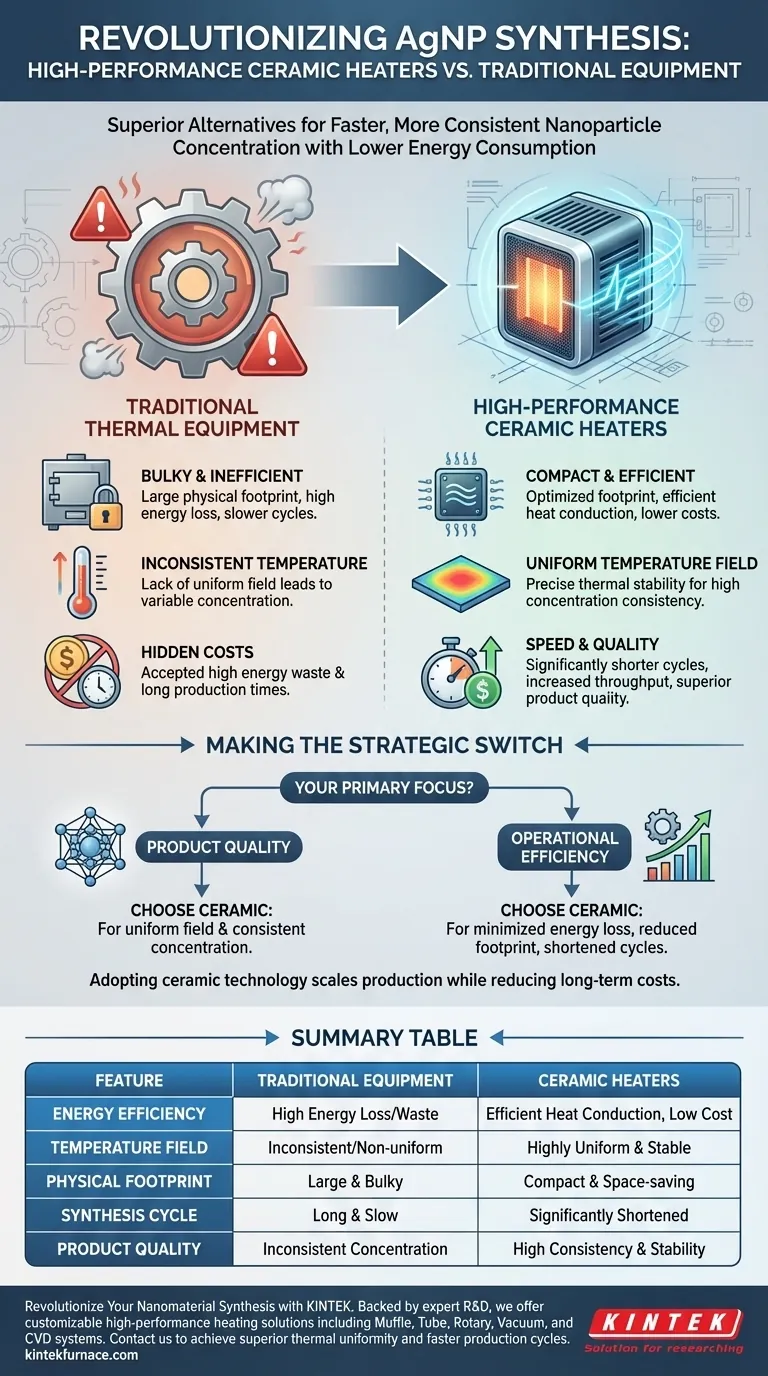

High-performance ceramic heaters offer a superior alternative to traditional thermal equipment for synthesizing silver nanoparticles (AgNPs). By leveraging efficient heat conduction and creating a uniform temperature field, these heaters solve critical issues regarding energy waste and process instability. This technology directly enables faster synthesis cycles and more consistent nanoparticle concentrations.

By replacing bulky, inefficient traditional thermal equipment with high-performance ceramic heaters, laboratories can achieve higher consistency in nanoparticle concentration while drastically reducing energy consumption and operational cycles.

Overcoming Traditional Limitations

Enhanced Energy Efficiency

Traditional thermal equipment is often characterized by high energy loss.

High-performance ceramic heaters address this by providing efficient heat conduction.

This ensures that energy is utilized effectively, directly lowering operational costs.

Optimizing Physical Footprint

Older thermal systems frequently require large amounts of physical space to operate.

Ceramic heaters offer a solution that is significantly more compact.

This reduces the equipment's spatial requirements, allowing for better utilization of laboratory or manufacturing floor space.

Improving Synthesis Quality and Speed

Achieving Thermal Uniformity

Preparing high-concentration silver nanoparticles requires precise thermal stability.

Ceramic heaters generate a uniform temperature field across the synthesis environment.

This uniformity is essential for ensuring that the concentration of nanoparticles remains consistent throughout the batch.

Shortening Production Cycles

Traditional methods often struggle with long cycle times required to maintain thermal stability.

The superior heat transfer properties of ceramic heaters allow the system to reach and maintain target temperatures quickly.

This capability significantly shortens the synthesis cycle, increasing overall throughput.

Understanding the Trade-offs

The Cost of Legacy Equipment

While traditional equipment is a known quantity, it creates a "hidden tax" on production through inefficiency.

The trade-off of sticking with older technology is accepted high energy loss and slower production times.

Precision vs. General Heating

General thermal equipment may suffice for basic heating tasks, but it lacks the precision required for sensitive nanomaterials.

For high-concentration AgNPs, the lack of a uniform temperature field in traditional units often leads to inconsistent product quality.

Making the Strategic Switch

Choosing the right heating element is critical for optimizing your chemical synthesis process.

- If your primary focus is product quality: Rely on ceramic heaters to provide the uniform temperature field necessary for maintaining consistent nanoparticle concentration.

- If your primary focus is operational efficiency: Switch to ceramic technology to minimize energy loss, reduce spatial footprint, and shorten production cycles.

Adopting high-performance ceramic heating is the logical step for laboratories aiming to scale production while reducing long-term operational costs.

Summary Table:

| Feature | Traditional Thermal Equipment | High-Performance Ceramic Heaters |

|---|---|---|

| Energy Efficiency | High energy loss and waste | Efficient heat conduction; low cost |

| Temperature Field | Inconsistent/Non-uniform | Highly uniform and stable |

| Physical Footprint | Large and bulky | Compact and space-saving |

| Synthesis Cycle | Long and slow | Significantly shortened cycles |

| Product Quality | Inconsistent concentration | High consistency and stability |

Revolutionize Your Nanomaterial Synthesis with KINTEK

Don't let outdated heating technology compromise your research outcomes or operational budget. KINTEK provides high-performance heating solutions designed for the rigorous demands of modern laboratories and industrial manufacturing.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temp furnaces—all fully customizable to your specific synthesis protocols.

Ready to achieve superior thermal uniformity and faster production cycles? Contact us today to discuss your unique needs with our technical specialists and discover the KINTEK advantage.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the key characteristics of silicon carbide that make it suitable for heating elements? Discover High-Temp Efficiency & Durability

- What is a heating element? The Engine of Controlled Heat for Your Applications

- What are the properties of Pyrolytic Boron Nitride (PBN) when used as a heating element? Unmatched Purity for High-Temp Processes

- What is the purpose of using S-type thermocouples for reheating furnace model validation? Ensure Simulation Accuracy

- How does the heating element's electrical resistance affect heat generation? Master Joule Heating for Efficient Thermal Systems

- What are the advantages of using SiC heating elements in sintering furnaces? Boost Efficiency and Versatility

- What contaminants should be kept away from heating elements and why? Prevent Catastrophic Failure and Extend Lifespan

- What are some applications of silicon carbide heating elements? Achieve High-Temp Precision in Labs & Industry