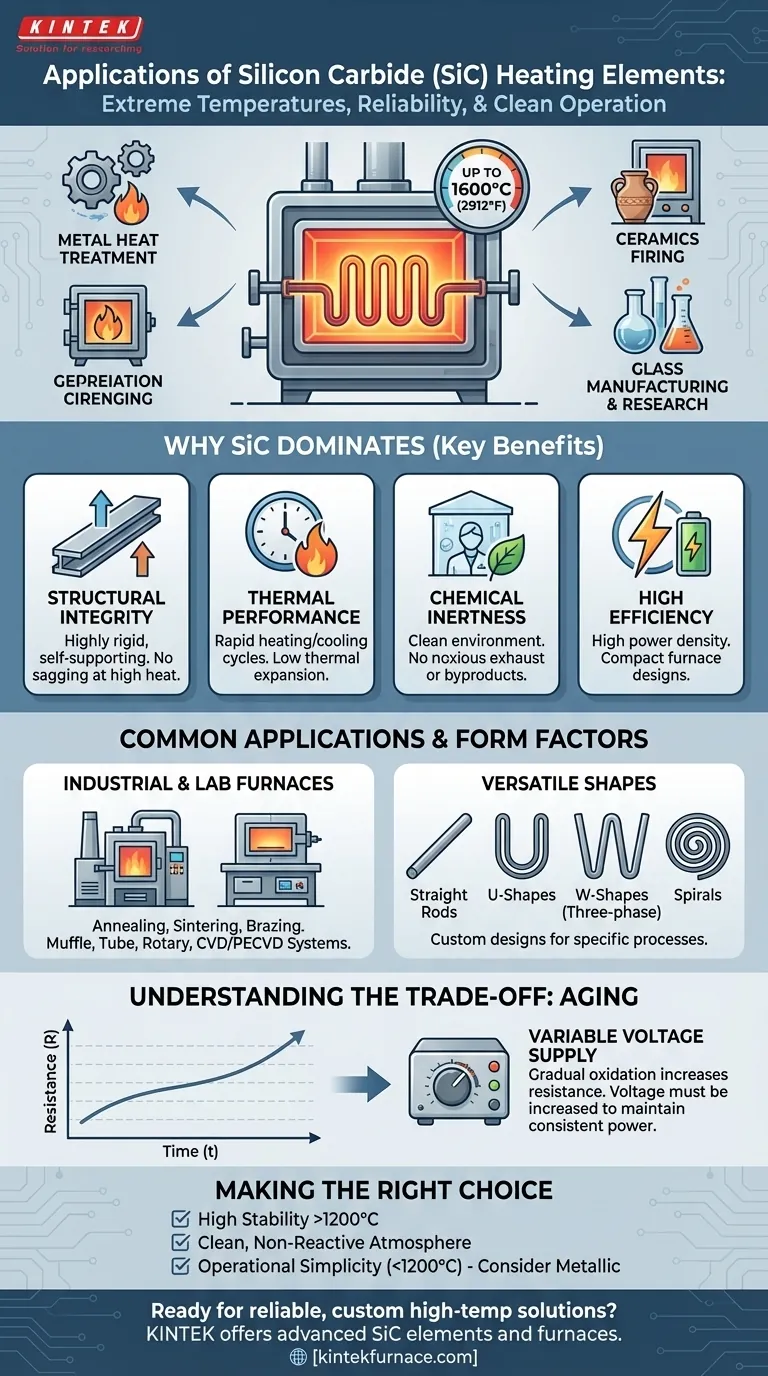

In short, silicon carbide (SiC) heating elements are used in a wide range of industrial and laboratory applications that demand extremely high temperatures, reliability, and clean operation. Their primary function is to provide heat for processes like metal heat treatment, ceramics firing, glass manufacturing, and in various research furnaces. They can achieve operating temperatures up to 1600°C (2912°F) and are valued for their structural stability and long service life in these demanding environments.

Silicon carbide is the material of choice when metallic heating elements fail. Its unique ability to remain rigid and chemically stable at extreme temperatures makes it indispensable for high-heat processes, but this performance requires managing a gradual "aging" process with specialized power controls.

Why SiC Dominates High-Temperature Applications

The preference for silicon carbide is not arbitrary; it is a direct result of its fundamental material properties. These characteristics make it uniquely suited for environments where other materials would quickly degrade or fail.

Exceptional Structural Integrity

Unlike many metallic elements that soften and sag over time at high temperatures (a phenomenon known as creep), SiC elements have no liquid phase. This means they remain highly rigid and self-supporting even when approaching their maximum temperature limits.

This structural integrity simplifies furnace design, as the elements do not require complex support systems and can be mounted vertically or horizontally.

Superior Thermal Performance

SiC elements offer low thermal expansion, což je činí mimořádně odolnými proti tepelnému šoku. This allows for rapid heating and cooling cycles without the risk of the element cracking or breaking.

This capability is critical in processes that require precise temperature ramps and fast cycle times, improving throughput and process control.

Chemical Inertness and Atmosphere Purity

SiC is a ceramic material that is highly resistant to oxidation and chemical corrosion. It is an electric resistance heater, meaning it produces no noxious exhaust or combustion byproducts.

This creates a clean heating environment, což je zásadní pro výrobu polovodičů, specializovaného skla a pokročilých materiálů, kde je kontaminace atmosféry nepřijatelná.

High Efficiency and Power Density

These elements have a high electrical resistance, allowing them to efficiently convert electrical energy directly into heat. They also boast a high power density, meaning they can generate a large amount of heat from a relatively small element.

This allows for more compact and powerful furnace designs compared to what might be possible with other heating technologies.

Common Applications and Form Factors

The versatility of SiC allows it to be manufactured in various shapes and sizes, fitting a diverse set of applications.

Industrial Furnaces

This is the largest application area. SiC elements are the workhorse in furnaces for annealing, sintering, brazing, and forging metals. They are also essential for firing ceramics and melting glass.

Laboratory and Research Equipment

On a smaller scale, SiC is used infekci in high-temperature laboratory furnaces, test kilns, and hot plates. Its ability to provide uniform, stable, and clean heat is ideal for research and development.

Versatile Element Shapes

SiC elements are available in many forms, including straight rods, U-shapes, W-shapes (or "three-phase"), and spirals. This flexibility allows for custom heater designs tailored to specific thermal processes, including large, uniform radiant panels.

Understanding the Key Trade-off: Aging

While SiC offers superior performance, it comes with a critical operational consideration that every user must understand.

The Process of Gradual Oxidation

Over its operational life, a silicon carbide element slowly oxidizes. This process forms a thin layer of silicon dioxide on its surface, which gradually increases the element's electrical resistance. This phenomenon is known as "aging."

The Need for Variable Voltage

As the resistance increases, a constant voltage would result in reduced power output (P = V²/R) and a drop in temperature. To counteract this, the voltage供給 must be gradually increased over the element's life to maintain a consistent power output and stable temperature.

This necessitates the use of a variable voltage power supply, such as a tap-switching transformer or a Silicon-Controlled Rectifier (SCR).

A Predictable and Manageable Factor

This aging process is not a flaw but a predictable characteristic. While it adds a layer of complexity to the power control system, it is a well-understood trade-off for achieving the longevity and extreme temperature performance that SiC provides.

Making the Right Choice for Your Application

To determine if SiC is the correct technology, consider your primary objective.

- If your primary focus is reaching temperatures above 1200°C with high stability: SiC is an industry standard, offering a level of rigidity and longevity that most metallic elements cannot match in this range.

- If your primary focus is maintaining a clean, non-reactive atmosphere: SiC's inertness and lack of exhaust make it ideal for sensitive processes in the semiconductor, laboratory, or advanced materials sectors.

- If your primary focus is operational simplicity at lower temperatures (below 1200°C): Be aware that SiC's requirement for a variable voltage power supply adds cost and complexity compared to simpler metallic elements suited for that range.

By understanding its unique properties and operational needs, you can leverage silicon carbide to achieve reliable, high-performance heating in the most demanding environments.

Summary Table:

| Key Feature | Benefit | Common Applications |

|---|---|---|

| High Temperature (up to 1600°C) | Enables extreme heat processes | Metal heat treatment, ceramics firing, glass manufacturing |

| Structural Stability | Resists sagging and creep, simplifying furnace design | Industrial furnaces for annealing and sintering |

| Chemical Inertness | Provides clean, non-reactive heating environment | Semiconductor production, advanced materials research |

| High Power Density | Efficient heat generation for compact furnace designs | Laboratory furnaces, test kilns, hot plates |

| Aging Management | Predictable performance with variable voltage control | Long-term reliable operations in high-heat settings |

Ready to enhance your high-temperature processes with reliable, custom heating solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced silicon carbide heating elements and furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and industrial needs. Contact us today to discuss how our solutions can deliver superior performance and efficiency for your lab or facility!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability