In a sintering furnace, Silicon Carbide (SiC) heating elements are primarily valued for their rapid heating and cooling speeds, energy efficiency, and operational versatility. They can function effectively in both oxidizing and reducing atmospheres, making them a flexible choice for a variety of thermal processes.

The decision to use SiC heating elements is not just about their inherent benefits, but about understanding their specific operational window. The choice between SiC and its common alternative, Molybdenum Disilicide (MoSi2), hinges almost entirely on your required maximum temperature and maintenance philosophy.

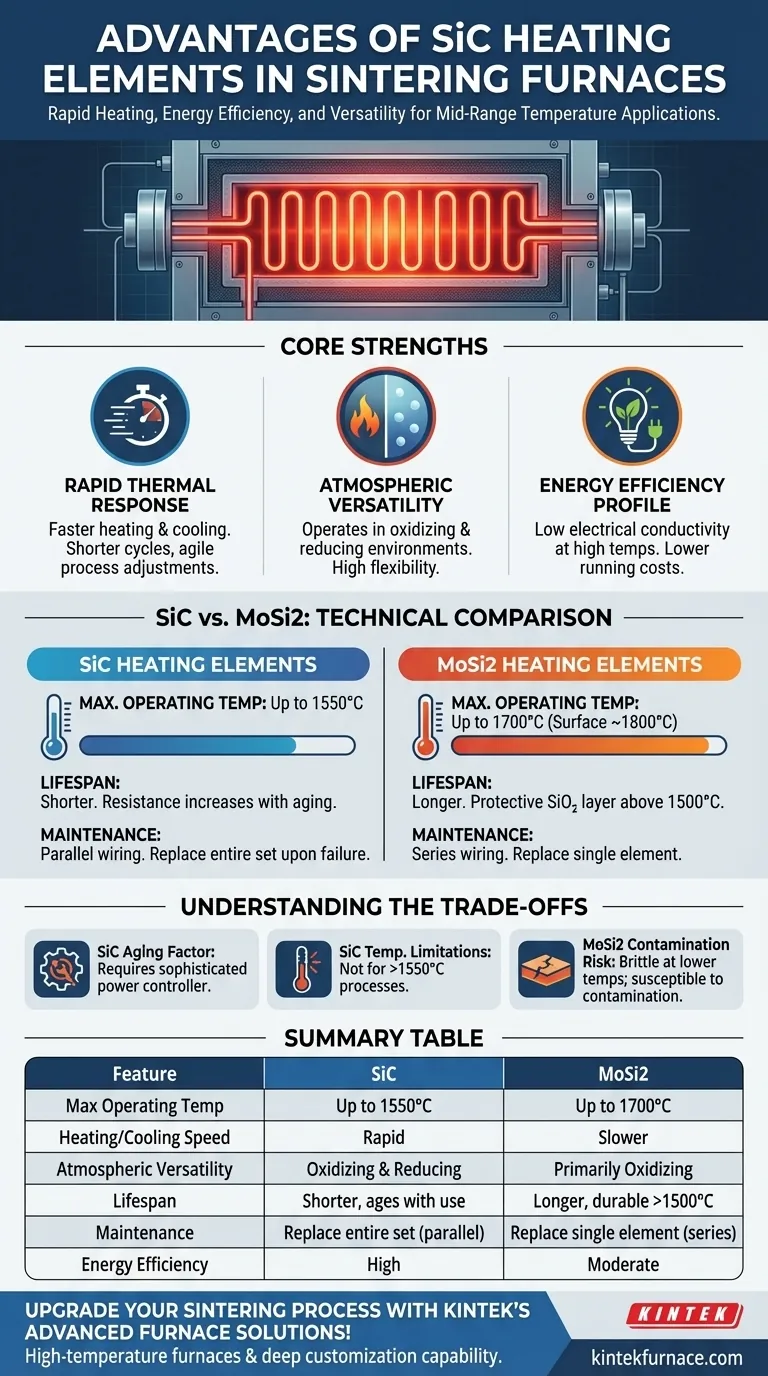

The Core Strengths of SiC Elements

The advantages of SiC make it a default choice for many mid-range temperature applications. Understanding these strengths is key to knowing if it fits your process.

Rapid Thermal Response

SiC elements are known for their ability to heat up and cool down quickly. This rapid response allows for shorter production cycles and more agile process adjustments compared to some alternatives.

Atmospheric Versatility

A significant advantage of SiC is its ability to perform well in a wide range of environments. It can operate reliably in both oxidizing (air) and reducing atmospheres, a flexibility not shared by all high-temperature elements.

Energy Efficiency Profile

SiC elements exhibit a low electrical conductivity at high temperatures. This characteristic contributes to greater energy efficiency during operation, which can lead to lower running costs over the element's lifespan.

SiC vs. MoSi2: A Technical Comparison

For sintering, the most critical comparison is between SiC and Molybdenum Disilicide (MoSi2) elements. The differences between them define their ideal applications.

Operating Temperature Range

This is the most important distinction. SiC elements have a maximum surface temperature of around 1600°C, limiting the furnace's internal temperature to approximately 1530-1550°C.

In contrast, MoSi2 elements can reach surface temperatures of 1800°C or more, allowing the furnace to reliably operate at 1600-1700°C. This makes MoSi2 essential for sintering high-temperature materials like certain high-translucency zirconia.

Lifespan and Durability

SiC elements tend to have a shorter lifespan, especially under frequent thermal cycling. Their electrical resistance also increases as they age, which can affect temperature uniformity over time.

MoSi2 elements can last significantly longer, particularly when operated consistently at temperatures above 1500°C. They form a protective silica (SiO₂) layer that grants them durability, but this also makes them brittle at lower temperatures.

Maintenance and Replacement

SiC elements are typically wired in parallel. When one element fails, its resistance changes dramatically, meaning you often need to replace the entire set or bank to maintain uniform heating.

MoSi2 elements are wired in series. A single failed element will break the circuit, but you can typically replace just the one failed component, simplifying maintenance.

Understanding the Trade-offs

Choosing a heating element means accepting a set of compromises. Objectivity is crucial for long-term success.

The Aging Factor of SiC

The primary drawback of SiC is that its resistance changes with use. This "aging" requires a more sophisticated power controller that can adjust the voltage to maintain a consistent power output and temperature. Failure to manage this leads to inconsistent sintering results.

Temperature Limitations of SiC

While excellent for many applications, SiC is fundamentally unsuitable for processes requiring temperatures above 1550°C. Attempting to push them beyond their limit drastically shortens their life and risks furnace damage.

The Contamination Risk of MoSi2

The key trade-off for MoSi2's high-temperature capability is its susceptibility to contamination. Improper furnace maintenance or the presence of certain reactive compounds can damage the protective silica layer, leading to premature failure.

Making the Right Choice for Your Sintering Process

Your material and process goals should dictate your choice of heating element. The right element is the one that provides the most stable and repeatable environment for your specific application.

- If your primary focus is on materials requiring temperatures below 1550°C: SiC offers a cost-effective and versatile solution with rapid heating cycles.

- If your primary focus is on high-temperature materials like advanced zirconia: MoSi2 is the only viable choice to achieve the necessary sintering temperatures consistently and reliably.

- If your primary focus is on simplified maintenance for a single failure: MoSi2's series wiring can make replacing a single broken element more straightforward.

- If your primary focus is on operational versatility across different atmospheres: SiC's ability to handle both oxidizing and reducing environments provides a distinct advantage.

Ultimately, selecting the correct heating element is fundamental to achieving precise, consistent, and reproducible results in your sintering operations.

Summary Table:

| Feature | SiC Heating Elements | MoSi2 Heating Elements |

|---|---|---|

| Max Operating Temperature | Up to 1550°C | Up to 1700°C |

| Heating/Cooling Speed | Rapid | Slower |

| Atmospheric Versatility | Oxidizing and reducing | Primarily oxidizing |

| Lifespan | Shorter, ages with use | Longer, durable above 1500°C |

| Maintenance | Replace entire set (parallel wiring) | Replace single element (series wiring) |

| Energy Efficiency | High | Moderate |

Upgrade your sintering process with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and reliability. Contact us today to discuss how we can support your specific sintering requirements!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan