At a minimum, you must protect heating elements from sulfur, phosphorous, oils, and cleaning agents. These substances are not merely "dirt"; they are chemical agents that can trigger catastrophic failure. At high temperatures, they initiate metallurgical or chemical reactions that degrade the element's material, leading to burnout far sooner than expected.

Contamination is the leading cause of premature heating element failure. Understanding the mechanism of this failure—whether it's a direct chemical attack or the creation of insulating hot spots—is the key to shifting from reactive repair to proactive prevention and maximizing element lifespan.

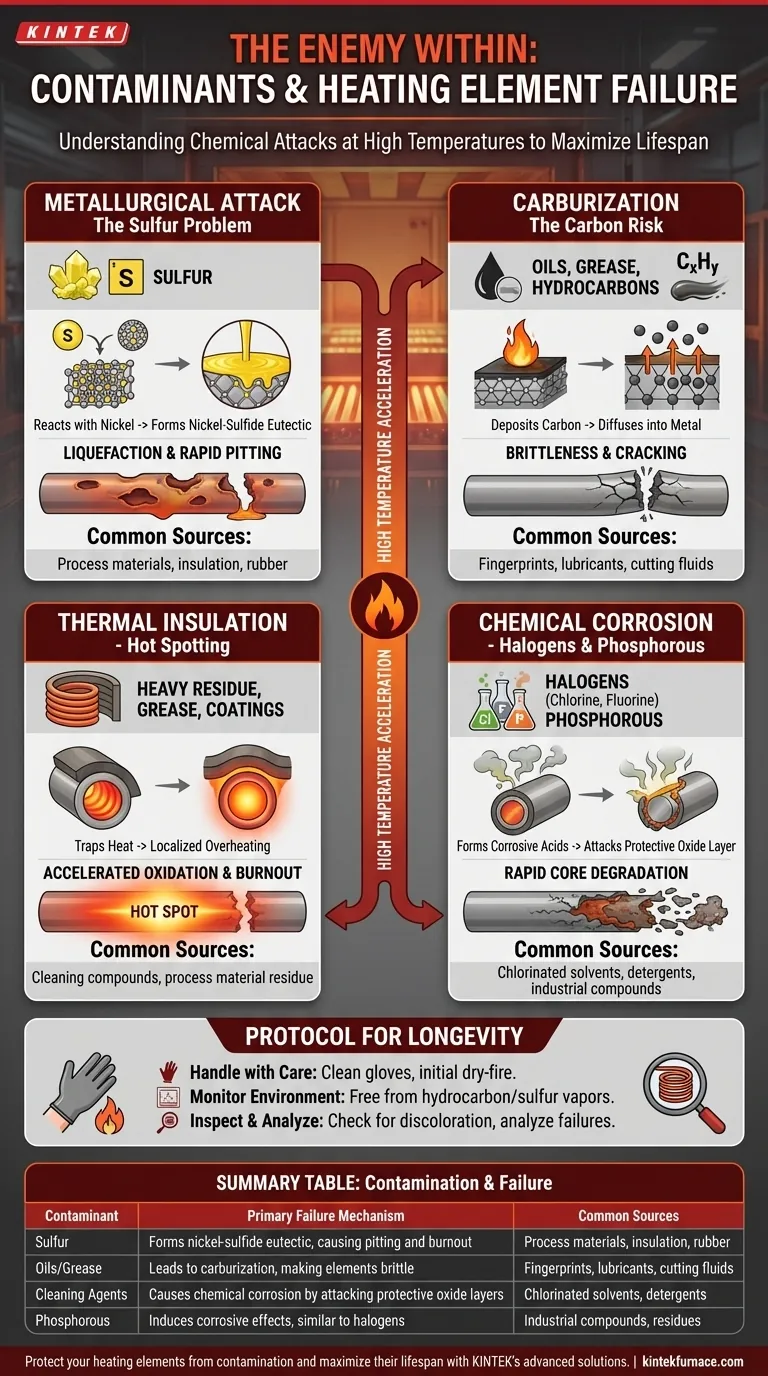

The Science of Contamination Failure

To prevent failure, you must first understand how it happens. Contaminants attack heating elements through several distinct mechanisms, each of which is accelerated by the high operating temperatures.

Metallurgical Attack: The Sulfur Problem

The most aggressive contaminant for common heating elements is sulfur. This is especially true for elements made from nickel-chromium (Nichrome) or nickel-based superalloys.

At high temperatures, sulfur reacts with nickel to form a nickel-sulfide eutectic. A eutectic is a mixture of substances that melts at a much lower temperature than its individual components. This new compound liquefies on the element's surface, causing rapid pitting, erosion, and burnout.

Carburization: The Carbon Contamination Risk

Contaminants like oil, grease, and hydrocarbon-based vapors introduce carbon to the element's environment. When these substances "burn off," they can deposit a layer of carbon onto the element's surface.

At high temperatures, this carbon can diffuse into the element's metal structure, a process called carburization. This makes the alloy brittle and far more susceptible to failure from physical stress or thermal cycling.

Thermal Insulation and Hot Spotting

Any substance that coats the element and does not immediately burn away can act as an insulating layer. This includes heavy oils, grease, and residue from cleaning compounds or process materials.

This layer traps heat, forcing the underlying section of the element to become much hotter than the surrounding areas to maintain the desired process temperature. This localized overheating, or "hot spot," dramatically accelerates oxidation and leads to a rapid point-of-failure.

Chemical Corrosion: Halogens and Phosphorous

Many industrial cleaning compounds contain halogens like chlorine or fluorine. At operating temperatures, these can form corrosive acids that attack the protective oxide layer that naturally forms on the surface of a healthy heating element.

Once this protective layer is compromised, the core alloy is exposed to rapid oxidation and degradation. Phosphorous, another common contaminant, can have a similarly corrosive effect.

Common Sources of Contamination in Practice

Recognizing the failure mechanism is only half the battle. You must be able to identify the source of the contaminant in your environment to effectively eliminate it.

Handling During Installation

Oils, grease, and salts from human fingerprints are a primary source of contamination on new elements. Always handle new elements with clean gloves.

Process Environment

The atmosphere within your furnace or process chamber is a critical factor. Vapors from lubricants on machinery, cutting fluids on parts, or sulfur-releasing materials (like certain types of insulation or rubber) can continuously expose elements to harm.

Cleaning and Maintenance

Using the wrong cleaning products can be worse than not cleaning at all. Avoid any chlorinated solvents or detergents near the elements. Even residue left from "safe" cleaners can create insulating hot spots if not fully removed.

A Protocol for Element Longevity

Adopting a strict protocol for handling and maintenance is the most effective way to ensure a long and reliable service life from your heating elements.

- If your primary focus is new installation: Handle elements only with clean gloves and perform an initial dry-fire or burn-off cycle (per manufacturer recommendations) to remove any residual surface contaminants in a controlled way.

- If your primary focus is ongoing maintenance: Regularly inspect elements for discoloration, scaling, or pitting, and ensure the process atmosphere is free from hydrocarbon vapors, sulfur compounds, and other known contaminants.

- If your primary focus is troubleshooting failures: Examine failed elements for signs of contamination, such as localized green residue (indicating nickel reactions) or severe pitting, to diagnose the root cause and prevent a recurrence.

By understanding that contamination is a chemical interaction, you gain the power to control it and protect your investment.

Summary Table:

| Contaminant | Primary Failure Mechanism | Common Sources |

|---|---|---|

| Sulfur | Forms nickel-sulfide eutectic, causing pitting and burnout | Process materials, insulation, rubber |

| Oils/Grease | Leads to carburization, making elements brittle | Fingerprints, lubricants, cutting fluids |

| Cleaning Agents | Causes chemical corrosion by attacking protective oxide layers | Chlorinated solvents, detergents |

| Phosphorous | Induces corrosive effects, similar to halogens | Industrial compounds, residues |

Protect your heating elements from contamination and maximize their lifespan with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs. Contact us today to learn how we can enhance your lab's reliability and efficiency!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance