At its core, a heating element is a component specifically designed to convert electrical energy into heat. It works through a process called Joule heating, where the resistance of a material creates thermal energy when an electric current is passed through it. This fundamental principle is the engine behind countless devices, from household toasters to industrial furnaces.

A heating element is not simply a wire that gets hot. It is a precisely engineered assembly that combines a resistive material with electrical insulators to safely and efficiently generate controlled heat for a specific application.

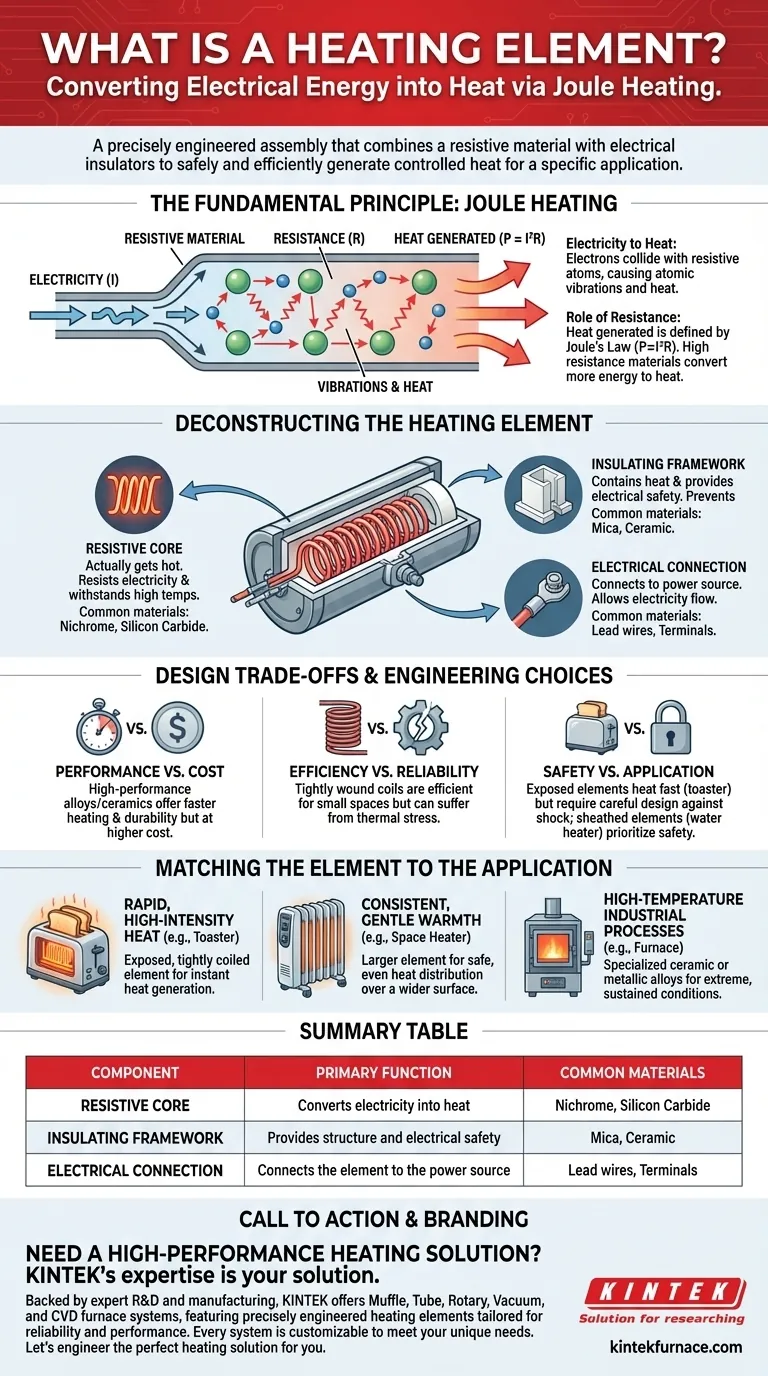

The Fundamental Principle: How Joule Heating Works

To understand a heating element, you must first understand the physics behind it. The entire operation hinges on a single, reliable principle.

From Electricity to Heat

When an electric current flows through a conductor, electrons move through the material. In a heating element, this material is chosen for its high electrical resistance. As the electrons are forced through, they collide with the atoms of the resistive material, causing vibrations. This atomic-scale friction manifests as heat.

The Role of Resistance

The amount of heat generated is defined by Joule's first law (P = I²R). This shows that the power (heat) generated is a function of the electrical current (I) and, most critically, the material's resistance (R). By carefully selecting a material with high resistance, engineers can ensure that a significant amount of electrical energy is converted into useful heat rather than being lost.

Deconstructing the Heating Element

A functional heating element is more than just its core resistive material. It is an assembly of parts, each with a critical role in safety and performance.

The Resistive Core

This is the component that actually gets hot. These materials are chosen for their ability to resist electricity and withstand very high temperatures without melting or degrading. Common materials include metal alloys like nichrome or advanced ceramics like silicon carbide.

The Insulating Framework

The immense heat generated by the core must be contained and directed. Insulating materials, such as mica or ceramic formers, provide a structural framework. They prevent the resistive core from making electrical contact with the body of the appliance, ensuring safety and efficiency.

The Electrical Connection

To function, the element must be connected to a power source. Lead connectors and wire terminals provide a safe and durable connection point, allowing electricity to flow into the resistive core to begin the heating process.

Understanding the Trade-offs in Element Design

The design of a heating element is a careful balance of competing factors. Engineers must make deliberate choices to optimize a component for its intended use.

Performance vs. Cost

High-performance alloys and ceramics can offer faster heating, higher maximum temperatures, and longer lifespans. However, these advanced materials often come at a significantly higher cost than more common materials like nichrome.

Efficiency vs. Reliability

The physical shape of the element—often a coil or ribbon—is designed to concentrate heat in a specific area. A tightly wound coil is very efficient for a small space, but this design can also create thermal stress that impacts the long-term reliability of the element.

Safety vs. Application

The choice of materials is directly linked to the application's safety requirements. An exposed-coil element in a toaster heats up almost instantly but requires careful design to prevent shock, whereas an element sheathed in metal for a water heater prioritizes electrical isolation over heating speed.

Matching the Element to the Application

The right design always depends on the final goal. By understanding the core purpose, you can appreciate the engineering choices behind the element's construction.

- If your primary focus is rapid, high-intensity heat (e.g., a toaster): The design prioritizes an exposed, tightly coiled element with high resistance to generate heat almost instantly.

- If your primary focus is consistent, gentle warmth (e.g., a space heater): The design often uses a larger element to distribute heat over a wider surface area, ensuring safe and even temperature distribution.

- If your primary focus is high-temperature industrial processes: The element must be built from specialized ceramic or metallic alloys capable of withstanding extreme and sustained operating conditions.

Ultimately, understanding these components reveals the deliberate engineering that safely turns the convenience of electricity into the power of controlled heat.

Summary Table:

| Component | Primary Function | Common Materials |

|---|---|---|

| Resistive Core | Converts electricity into heat | Nichrome, Silicon Carbide |

| Insulating Framework | Provides structure and electrical safety | Mica, Ceramic |

| Electrical Connection | Connects the element to the power source | Lead wires, Terminals |

Need a High-Performance Heating Solution?

Whether you require rapid heating, consistent warmth, or extreme temperature capabilities for industrial processes, the right heating element is critical. KINTEK's expertise is your solution.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all featuring precisely engineered heating elements tailored for reliability and performance. Every system is customizable to meet your unique laboratory or industrial needs.

Let's engineer the perfect heating solution for you. Contact our experts today to discuss your project!

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs

- What is the temperature range where MoSi2 heating elements should not be used for long periods? Avoid 400-700°C to Prevent Failure

- What role do MoSi2 heating elements play in 1500 °C experiments? Key to Stability and Precision

- How can high temperature heating elements be customized for different applications? Tailor Elements for Peak Performance

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs