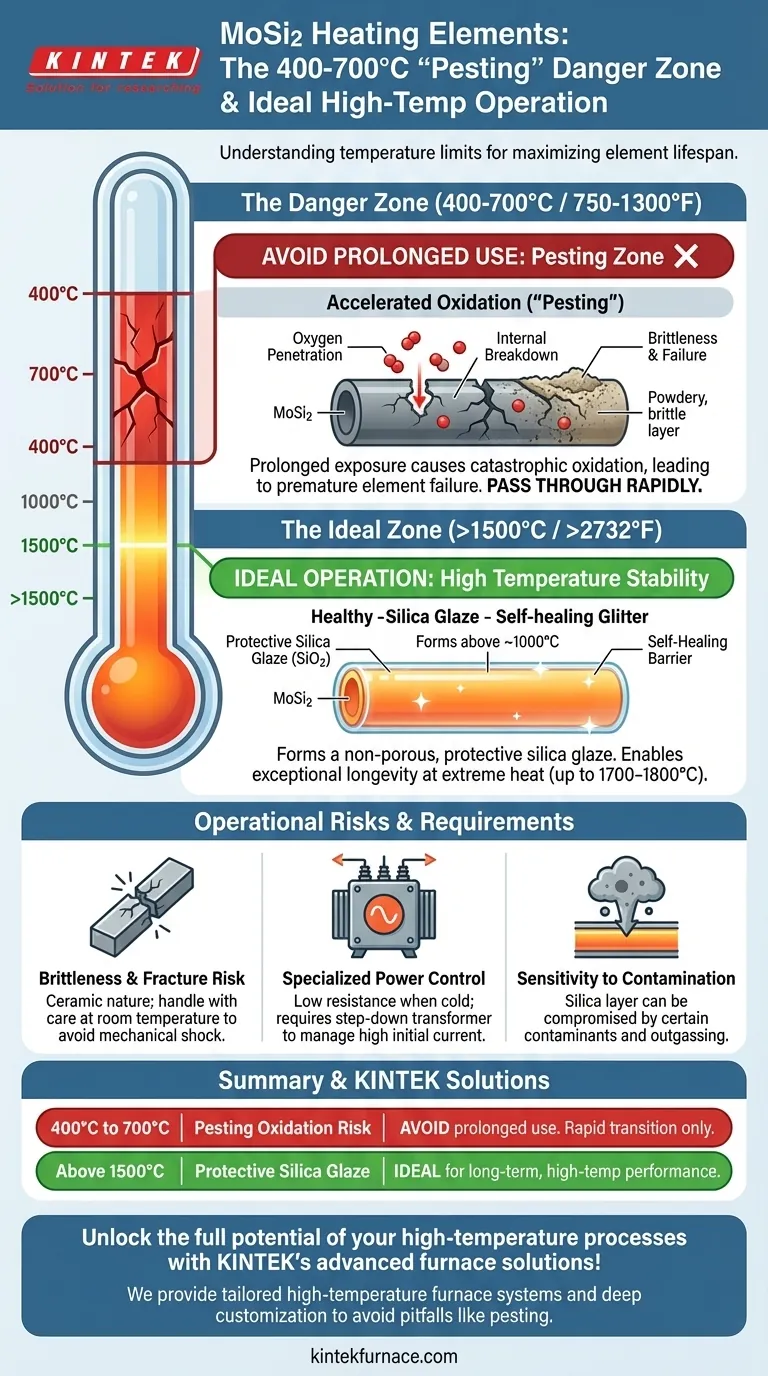

For extended operational periods, you must avoid using Molybdenum Disilicide (MoSi2) heating elements in the temperature range of 400°C to 700°C (approximately 750°F to 1300°F). Operating within this specific window causes a destructive form of accelerated oxidation that can lead to premature element failure.

The core issue with MoSi2 elements is not that they cannot handle low temperatures, but that they must pass through the 400-700°C range quickly. Prolonged exposure in this zone triggers a catastrophic oxidation process, while operation at very high temperatures is precisely where these elements excel.

The "Pesting" Phenomenon: Why 400-700°C is a Danger Zone

The limitation of MoSi2 elements is not about general low-temperature use, but about a specific chemical reaction that occurs within a narrow band. Understanding this mechanism is key to maximizing element lifespan.

Understanding Accelerated Oxidation

In the 400-700°C range, MoSi2 elements are susceptible to a phenomenon often called "pesting". This is a rapid, disintegrating oxidation that attacks the element's structure.

Instead of forming a protective outer layer, oxygen penetrates the material and causes it to break down into a powder of molybdenum oxide and silica.

The Result: Brittleness and Failure

This internal oxidation causes the element to swell, become brittle, and physically degrade. An element subjected to prolonged "pesting" will fail far sooner than one operated correctly.

This is why frequent on/off cycles or long "idling" periods at these low temperatures are strongly discouraged.

The Solution: Rapid Temperature Transition

The proper operational procedure is to heat the furnace rapidly through the 400-700°C range. By minimizing the time spent in this danger zone, the "pesting" reaction does not have sufficient time to cause significant damage.

MoSi2's True Strength: High-Temperature Operation

While MoSi2 elements have a critical weakness at low temperatures, they are specifically engineered for superior performance and longevity at extreme heat.

Designed for Extreme Heat

These elements are designed to operate continuously at furnace temperatures up to 1600-1700°C (2912-3092°F), with some models having element surface temperatures reaching 1800°C or higher.

The Protective Silica Glaze

Above approximately 1000°C, MoSi2 elements form a thin, self-healing layer of pure silica glass (SiO2) on their surface. This non-porous glaze acts as a protective barrier, preventing further oxidation and enabling their exceptionally long life at high temperatures.

This "auto-repair" function means that any minor surface flaws that develop during operation are quickly sealed by the viscous glass layer.

Superior Longevity Above 1500°C

When operated correctly and consistently above 1500°C, MoSi2 elements often last significantly longer than other common high-temperature elements, such as those made from Silicon Carbide (SiC).

Understanding the Trade-offs and Operational Risks

To successfully implement MoSi2 elements, you must also be aware of their distinct operational requirements and physical limitations.

Brittleness and Fracture Risk

MoSi2 elements are a type of ceramic and are inherently brittle at room temperature. They are susceptible to fracture from mechanical shock or impact and must be handled with care during installation and maintenance.

Specialized Power Control

These elements have a very low electrical resistance at room temperature, which increases significantly as they heat up. This requires a sophisticated power control system, typically involving a step-down transformer, to manage the high initial current draw and prevent damage. This adds to the initial system cost.

Sensitivity to Contamination

The protective silica layer can be compromised by certain contaminants. Technicians must ensure proper furnace maintenance and avoid issues like outgassing from improperly dried paints or refractory materials, which can attack the elements and shorten their lifespan.

How to Apply This to Your Project

Your operational strategy should be directly informed by your primary process goal.

- If your primary focus is maximum furnace life and reliability: Ensure your control system is programmed to ramp temperature up and down through the 400-700°C range as quickly as is feasible. Avoid long hold or idle periods within this zone.

- If your primary focus is running processes at very high temperatures (above 1500°C): MoSi2 elements are an ideal choice, as their self-healing protective layer provides unmatched stability and longevity in these extreme conditions.

- If your primary focus is frequent cycling or low-temperature work: Carefully evaluate if MoSi2 is the right choice. The repeated passes through the "pesting" zone and the lack of high-temperature operation to form a robust protective layer may lead to a shorter-than-expected life.

By understanding both the strengths and the specific weaknesses of MoSi2, you can engineer a highly reliable and long-lasting high-temperature system.

Summary Table:

| Temperature Range | Risk/Recommendation | Key Details |

|---|---|---|

| 400°C to 700°C | Avoid prolonged use | Causes pesting oxidation, leading to brittleness and premature failure |

| Above 1500°C | Ideal for long-term use | Forms protective silica glaze, ensures superior longevity and performance |

Unlock the full potential of your high-temperature processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, helping you avoid common pitfalls like pesting in MoSi2 elements and achieve reliable, long-lasting performance. Contact us today to discuss how we can enhance your lab's efficiency and results!

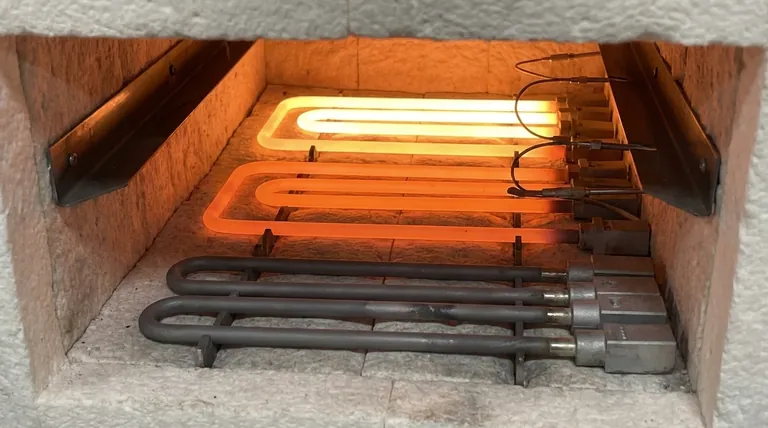

Visual Guide

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How can high temperature heating elements be customized for different applications? Tailor Elements for Peak Performance

- What are the primary applications of Molybdenum Disilicide (MoSi2) heating elements in furnaces? Achieve High-Temp Excellence

- What is the temperature range for MoSi2 heating elements? Maximize Lifespan in High-Temp Applications

- What ceramic materials are commonly used for heating elements? Discover the Best for Your High-Temp Needs

- What types of molybdenum disilicide heating elements are available? Choose the Right Element for Your High-Temp Needs