At its core, a Pyrolytic Boron Nitride (PBN) heating element is defined by its exceptional purity and chemical stability at extreme temperatures. Unlike conventional heaters, PBN is engineered to operate in high-vacuum or inert environments up to 1873K without outgassing, making it an essential component for processes where any form of contamination would be catastrophic.

The primary value of a PBN heater is not just its ability to generate heat, but its ability to do so without introducing impurities. It is chosen for applications where maintaining a pristine chamber environment is more critical than the cost of the component itself.

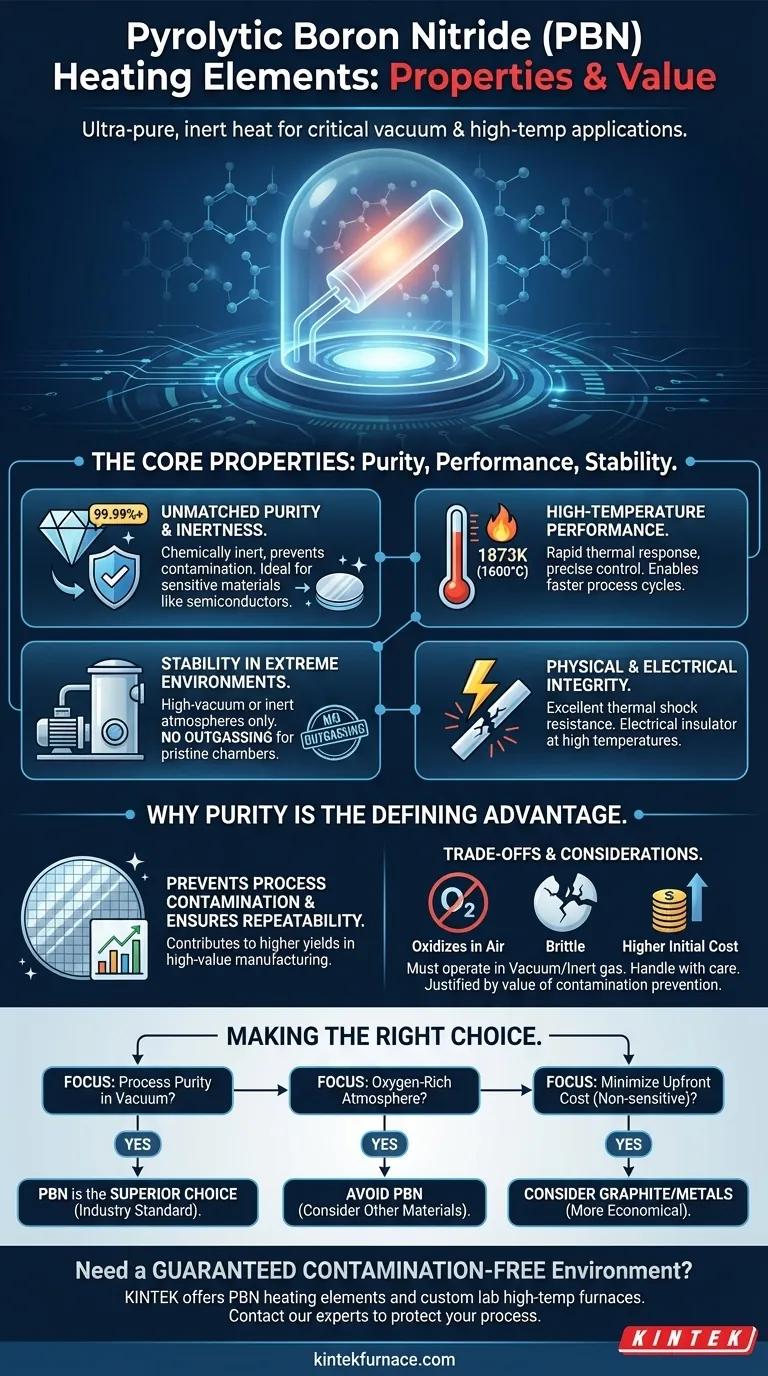

The Core Properties of PBN Heating Elements

To understand why PBN is specified for demanding applications, we must break down its unique combination of thermal, chemical, and electrical properties.

Unmatched Purity and Inertness

PBN is one of the purest materials available, typically rated at 99.99% or higher. This extreme purity means it is chemically inert and will not react with or contaminate sensitive materials.

This property is crucial in semiconductor manufacturing and single-crystal growth, where even trace impurities can alter electrical properties and cause device failure.

High-Temperature Performance

PBN heaters can reach ultra-high temperatures, up to 1873K (1600°C), and can do so in a very short time.

This rapid thermal response allows for precise temperature control and faster process cycles, increasing throughput in a production environment.

Stability in Extreme Environments

The defining characteristic of a PBN heater is its stability in high-vacuum or inert atmospheres. It does not break down or release any volatile components, a phenomenon known as outgassing.

This ensures that the process chamber remains clean, which is a non-negotiable requirement for technologies like molecular beam epitaxy (MBE) and thin-film deposition.

Physical and Electrical Integrity

PBN exhibits exceptional thermal shock resistance, meaning it can withstand rapid changes in temperature without cracking or failing.

Furthermore, it is an excellent electrical insulator, even at peak operating temperatures. This ensures that the heating current is contained entirely within the element, preventing electrical interference with the process.

Why Purity is the Defining Advantage

While many materials can get hot, few can do so with the cleanliness of PBN. This single factor is what drives its adoption in high-value manufacturing.

Preventing Process Contamination

In semiconductor fabrication, any unwanted atoms can ruin the delicate electronic structures being created. A conventional heater might release metallic ions or gases that get embedded in the silicon wafer.

A PBN heater, by its very nature, eliminates this entire class of failure modes. It provides pure, radiant heat without any accompanying contamination.

Ensuring Repeatability and Yield

By maintaining a pristine chamber environment, PBN heaters contribute directly to process stability.

This leads to higher yields and more consistent, repeatable results from one production run to the next, a critical factor in scaling any advanced manufacturing process.

Understanding the Trade-offs

No material is perfect for every situation. The specialized nature of PBN brings with it a specific set of limitations that are crucial to understand.

Atmospheric Constraints

PBN's stability is exclusive to vacuum or inert gas environments. It will oxidize and degrade if operated at high temperatures in the presence of air or other oxygen-rich atmospheres.

Mechanical Fragility

Like most high-purity ceramics, PBN is a brittle material. It must be handled with care during installation and maintenance to avoid chipping or cracking, which would lead to premature failure.

High Initial Cost

The complex chemical vapor deposition (CVD) process used to create high-purity PBN makes it significantly more expensive than heaters made from materials like graphite or refractory metals. This cost must be justified by the value of preventing process contamination.

Making the Right Choice for Your Goal

Selecting a PBN heater is a decision driven entirely by the sensitivity of your process. Your choice should be based on a clear understanding of your primary technical and business objectives.

- If your primary focus is process purity and yield in a vacuum: PBN is the industry standard and the superior choice for preventing contamination.

- If your primary focus is operating in an oxygen-rich atmosphere: PBN is fundamentally unsuitable and you must consider a different material.

- If your primary focus is minimizing upfront equipment cost for a non-sensitive process: A more conventional heater made from graphite or a refractory metal would be a more economical solution.

Ultimately, choosing a PBN heating element is an investment in the absolute integrity of your process environment.

Summary Table:

| Property | Key Characteristic | Benefit |

|---|---|---|

| Purity & Inertness | 99.99%+ purity, chemically inert | Prevents contamination of sensitive materials (e.g., semiconductors) |

| High-Temp Performance | Operates up to 1873K (1600°C) | Rapid thermal response for precise control and faster cycles |

| Environmental Stability | Stable in high-vacuum/inert atmospheres | No outgassing, ensures a pristine process chamber |

| Physical/Electrical | Excellent thermal shock resistance, electrical insulator | Reliable performance and prevents electrical interference |

Need a heating element that guarantees a contamination-free environment?

For processes where even trace impurities can cause failure—such as semiconductor manufacturing, MBE, or single-crystal growth—a Pyrolytic Boron Nitride (PBN) heater is the definitive solution. It provides pure, radiant heat without outgassing, directly contributing to higher yields and repeatable results.

Backed by expert R&D and manufacturing, KINTEK offers PBN heating elements and other lab high-temp furnaces (Muffle, Tube, Rotary, Vacuum, CVD systems), all customizable for your unique needs.

Contact our experts today to discuss how a PBN heating element can protect your high-value processes.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality