The definitive advantage of using a vacuum oven for drying NiFe2O4/biochar samples lies in its ability to remove solvents from deep micropores without thermally degrading the material. By lowering the environmental pressure, typically at a moderate 80°C, you accelerate the volatilization of residual water and ethanol while shielding the composite from oxidation.

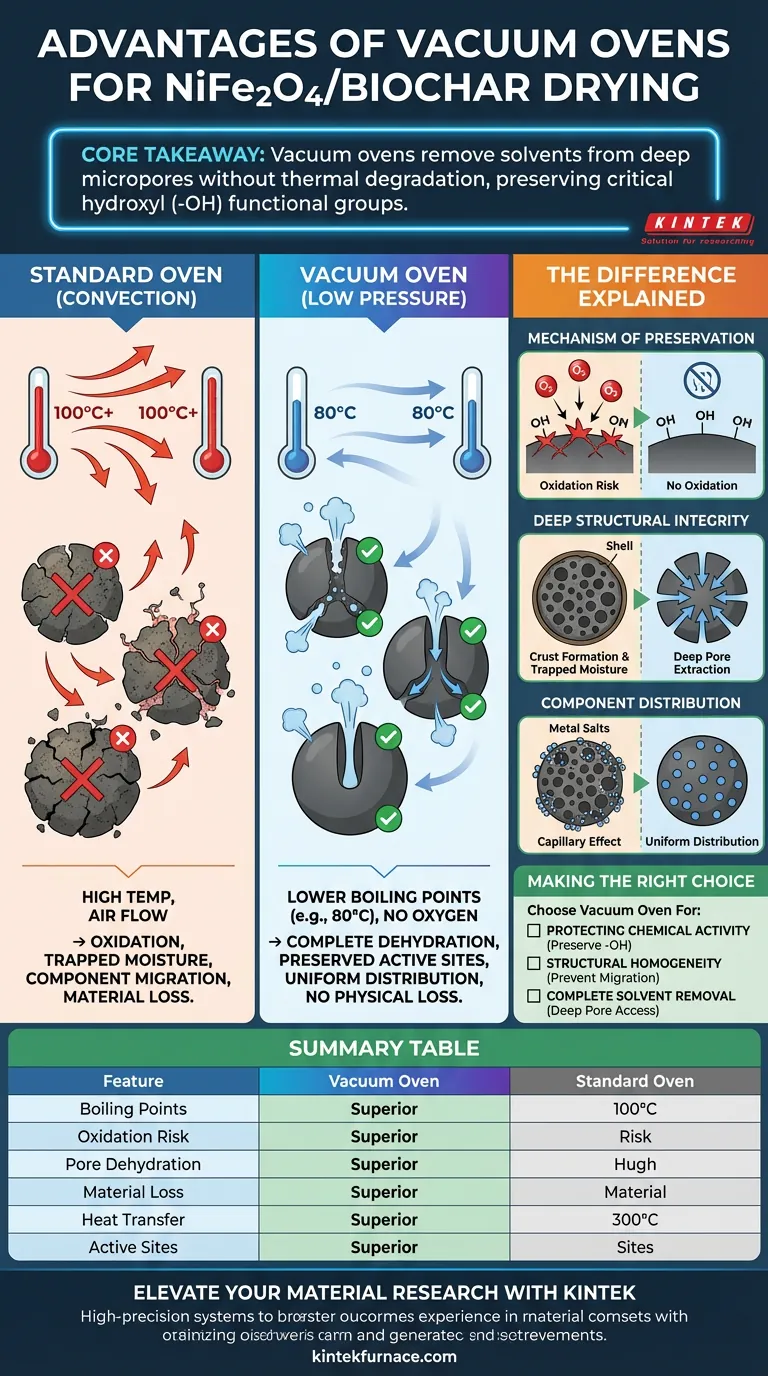

Core Takeaway Standard convection drying often leads to surface oxidation and trapped internal moisture due to the high temperatures required to overcome atmospheric pressure. A vacuum oven solves this by lowering the boiling point of solvents, allowing for complete structural dehydration while preserving the critical hydroxyl (-OH) functional groups that define the material's chemical activity.

The Mechanism of Preservation

Lowering Solvent Boiling Points

In a standard oven, you must heat solvents to their boiling points (e.g., 100°C for water) to induce evaporation.

In a vacuum oven, reducing the internal pressure significantly lowers these boiling points. This allows you to dry samples at roughly 80°C (or lower) with the same efficiency as a much hotter standard oven, sparing the material from thermal stress.

Preventing Oxidation of Active Sites

NiFe2O4/biochar composites rely heavily on surface functional groups, specifically hydroxyl groups (-OH), for their adsorption capabilities.

Standard ovens constantly circulate hot air, which promotes oxidation and can degrade these functional groups. A vacuum environment removes oxygen from the equation, ensuring these active sites remain intact and chemically available for future applications.

Deep Structural Integrity

Accessing Micropores

Biochar is highly porous. In atmospheric drying, surface moisture evaporates first, potentially forming a "crust" that traps residual water and ethanol deep within the micropores.

Vacuum drying creates a pressure differential that draws solvents out from the deepest pores of the carrier. This ensures the thorough removal of moisture that standard heating often misses.

Stabilizing Component Distribution

When drying composite materials, rapid surface evaporation in a standard oven can cause the "capillary effect."

This phenomenon draws active components (like metal salts) toward the outer surface, resulting in uneven distribution. Vacuum drying mitigates this, ensuring the NiFe2O4 remains uniformly distributed throughout the biochar matrix rather than migrating to the exterior.

Preventing Physical Loss

Standard ovens rely on airflow (convection) to distribute heat. For fine powders like biochar composites, this airflow can physically blow the sample away.

Vacuum ovens operate in a static environment without turbulent airflow, eliminating the risk of powder loss or cross-contamination.

Understanding the Trade-offs

Heat Transfer Efficiency

In a vacuum, there is no air to transfer heat via convection. Heat transfer relies solely on conduction (from the shelf) and radiation. This means the initial heating ramp-up can be slower compared to a forced-air oven, requiring patience during the stabilization phase.

Equipment Constraints

Vacuum drying is generally a batch process with limited capacity compared to large industrial convection ovens. It requires more precise monitoring of pressure seals and pump maintenance, introducing a layer of operational complexity that standard ovens lack.

Making the Right Choice for Your Goal

To maximize the efficacy of your NiFe2O4/biochar samples, align your drying method with your specific technical requirements:

- If your primary focus is protecting chemical activity: Use a vacuum oven to prevent the oxidation of hydroxyl groups and preserve adsorption sites.

- If your primary focus is structural homogeneity: Use a vacuum oven to prevent component migration and ensure uniform dispersion of NiFe2O4.

- If your primary focus is complete solvent removal: Use a vacuum oven to ensure deep-pore volatilization of ethanol and water that standard heating cannot reach without damage.

By controlling pressure, you control the purity and potency of your final composite material.

Summary Table:

| Feature | Vacuum Oven | Standard Convection Oven |

|---|---|---|

| Boiling Points | Significantly lowered via pressure | Standard (e.g., 100°C for water) |

| Oxidation Risk | Low (Oxygen-free environment) | High (Continuous hot air flow) |

| Pore Dehydration | Excellent (Deep-pore extraction) | Moderate (Risk of trapped moisture) |

| Material Loss | None (Static environment) | High (Airflow can blow powders) |

| Heat Transfer | Conduction & Radiation | Convection |

| Active Sites | Preserves -OH functional groups | Risk of thermal degradation |

Elevate Your Material Research with KINTEK

Don't let oxidation or surface crusting compromise your NiFe2O4/biochar composites. Backed by expert R&D and manufacturing, KINTEK offers high-precision Vacuum, Muffle, Tube, and CVD systems tailored for sensitive lab applications. Our customizable high-temperature furnaces ensure your samples retain their structural integrity and chemical activity through superior pressure and thermal control.

Ready to optimize your drying process? Contact us today to discuss your unique research needs with our technical team!

Visual Guide

References

- Huagen Liang, Fu Chen. Facile preparation of NiFe2O4/biochar composite adsorbent for efficient adsorption removal of antibiotics in water. DOI: 10.1007/s44246-023-00094-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is a vacuum furnace used? Achieve Superior Heat Treatment with Purity and Precision

- What was the traditional insulation setup in vacuum furnaces, and how has it changed? Discover the Modern All-Felt System

- What is the purpose of using a vacuum oven for h-NCM(OH)2? Optimize Your Cathode Material Research

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is controlling sulfur levels beneficial for the removal of tin impurities? Optimize Vacuum Steelmaking Efficiency

- What conditions does a vacuum furnace provide for Nb3Sn repair? Precision Heat and High Vacuum for Superconductors

- What industries commonly use vacuum furnace chillers? Discover Key Applications in Aerospace, Semiconductors & More

- Why is a vacuum drying oven essential for lithium-ion battery electrodes? Ensure Stability and Cycle Life