In short, the primary advantages of Molybdenum Disilicide (MoSi2) heating elements are their ability to operate at exceptionally high temperatures, their remarkably long service life, and their unique operational flexibility. They achieve this through a self-healing protective layer that forms in oxidizing atmospheres, making them a default choice for the most demanding industrial and laboratory furnaces.

MoSi2 elements are not just a component; they are an enabling technology. Their core benefit lies in providing stable, reliable, and long-lasting heat in extreme temperature environments (up to 1900°C) where most other electric heating elements simply cannot function.

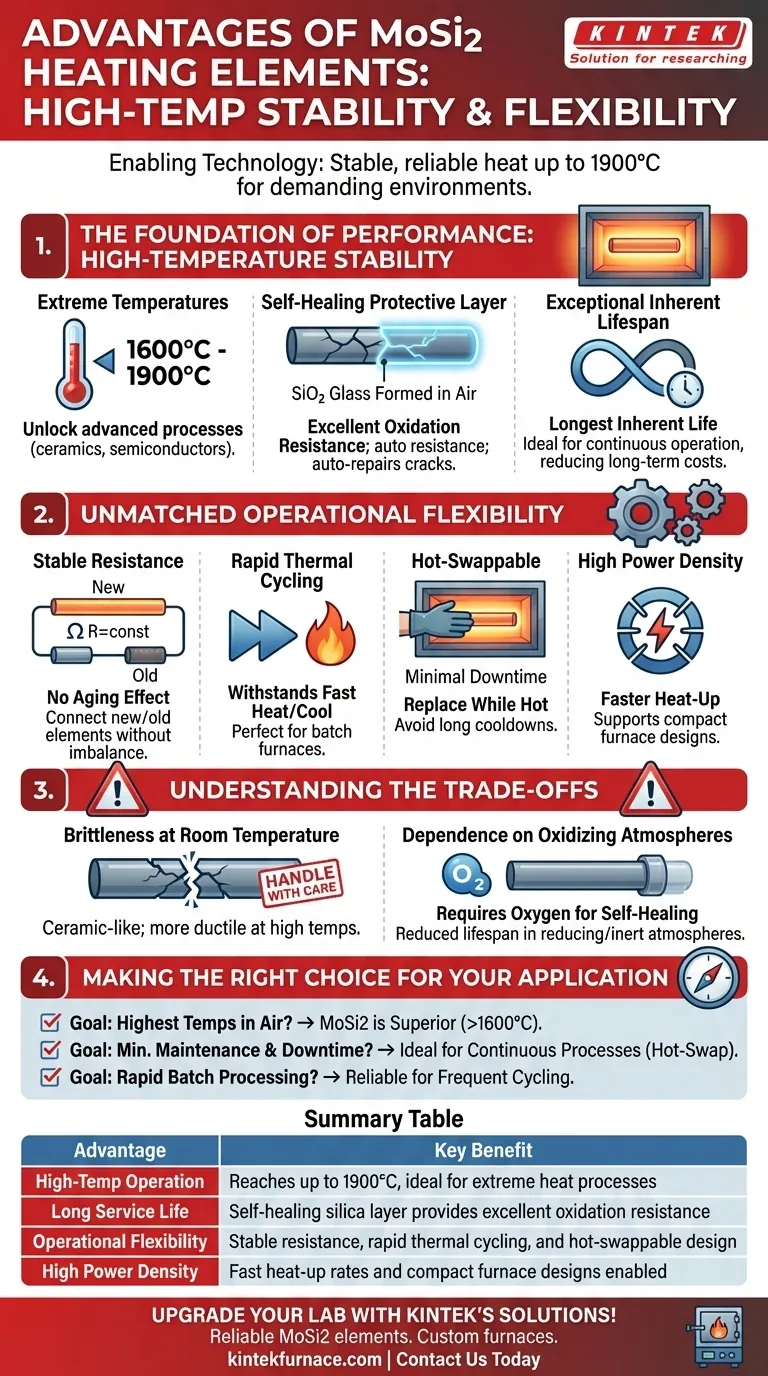

The Foundation of Performance: High-Temperature Stability

The defining characteristic of MoSi2 elements is their robust performance under extreme heat, which stems from their unique material science.

Reaching Extreme Temperatures

MoSi2 elements can achieve the highest operating temperatures among common metallic resistance heating elements. They reliably operate between 1600°C and 1700°C, with specialized grades capable of reaching up to 1900°C.

This capability unlocks processes for materials like advanced ceramics, glass, and semiconductors that require extreme heat treatment in an air atmosphere.

The Self-Healing Protective Layer

The longevity of MoSi2 elements is due to their excellent oxidation resistance. When heated in an oxygen-rich environment, a thin, non-porous layer of silica glass (SiO2) forms on the element's surface.

This passive glaze is self-healing. If a crack or damage occurs, the underlying material is exposed to oxygen, immediately forming new SiO2 to reseal the element and protect it from further degradation.

Exceptional Inherent Lifespan

Because of this auto-repair function, MoSi2 elements have the longest inherent lifespan of all metallic electric heating elements. Their durability makes them suitable for continuous, uninterrupted operation in industrial settings, reducing replacement frequency and long-term costs.

Unmatched Operational Flexibility

Beyond pure temperature resistance, MoSi2 elements offer practical advantages that simplify furnace operation and maintenance, directly impacting uptime and cost.

Stable Resistance Over Time

Unlike many other heating elements (such as Silicon Carbide), the electrical resistance of MoSi2 does not change significantly with age or use.

This is a critical advantage. It means new elements can be connected in series with older ones without causing power imbalances or premature failure, drastically simplifying maintenance and spare parts management.

Rapid Thermal Cycling

MoSi2 elements can withstand rapid heating and cooling cycles without suffering thermal shock or degradation. This makes them ideal for batch furnaces that are frequently started and stopped, not just for continuous operation.

Hot-Swappable for Minimal Downtime

A failed element can often be replaced while the furnace is still hot. This unique feature minimizes production downtime, as there is no need to wait for a full furnace cooldown and reheat cycle, which can take many hours or even days.

High Power Density

These elements support high watt loadings, meaning they can produce a great deal of heat from a relatively small surface area. This allows for faster furnace heat-up rates and potentially more compact furnace designs.

Understanding the Trade-offs

While powerful, MoSi2 elements are not a universal solution. Understanding their limitations is key to successful implementation.

Brittleness at Room Temperature

MoSi2 is a ceramic-like material and is very brittle at ambient temperatures. Careful handling is required during installation to prevent fracture. The elements become more ductile and less fragile once they reach high temperatures.

Dependence on Oxidizing Atmospheres

The self-healing SiO2 layer—the very source of the element's longevity—can only form in the presence of oxygen. Their use in reducing or inert atmospheres requires careful consideration and may significantly shorten their lifespan or lower their maximum operating temperature.

Making the Right Choice for Your Application

Use these points to determine if MoSi2 elements align with your primary operational goal.

- If your primary focus is achieving the highest possible temperatures in air: MoSi2 is the superior choice for any application requiring sustained operation above 1600°C.

- If your primary focus is minimizing maintenance and production downtime: The stable resistance and ability to hot-swap elements make MoSi2 ideal for continuous industrial processes.

- If your primary focus is rapid batch processing: The element's tolerance for fast thermal cycling ensures reliability in furnaces that are frequently heated and cooled.

Ultimately, choosing MoSi2 is an investment in high-temperature stability, operational reliability, and long-term performance.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| High-Temperature Operation | Reaches up to 1900°C, ideal for extreme heat processes |

| Long Service Life | Self-healing silica layer provides excellent oxidation resistance |

| Operational Flexibility | Stable resistance, rapid thermal cycling, and hot-swappable design |

| High Power Density | Fast heat-up rates and compact furnace designs enabled |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable heating elements like MoSi2, ensuring precise temperature control and durability for demanding applications. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how we can enhance your efficiency and performance!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C