The vast majority of common heating elements are made from an alloy called Nichrome, which is typically composed of about 80% nickel and 20% chromium. This specific combination provides the high electrical resistance needed to generate heat efficiently while also resisting degradation and oxidation in open air, making it the standard for countless everyday appliances.

The choice of a heating element is not about finding one "best" material. It is a precise engineering decision that balances a material's electrical resistance, its ability to withstand high temperatures without melting, and its capacity to resist chemical breakdown in its operating environment.

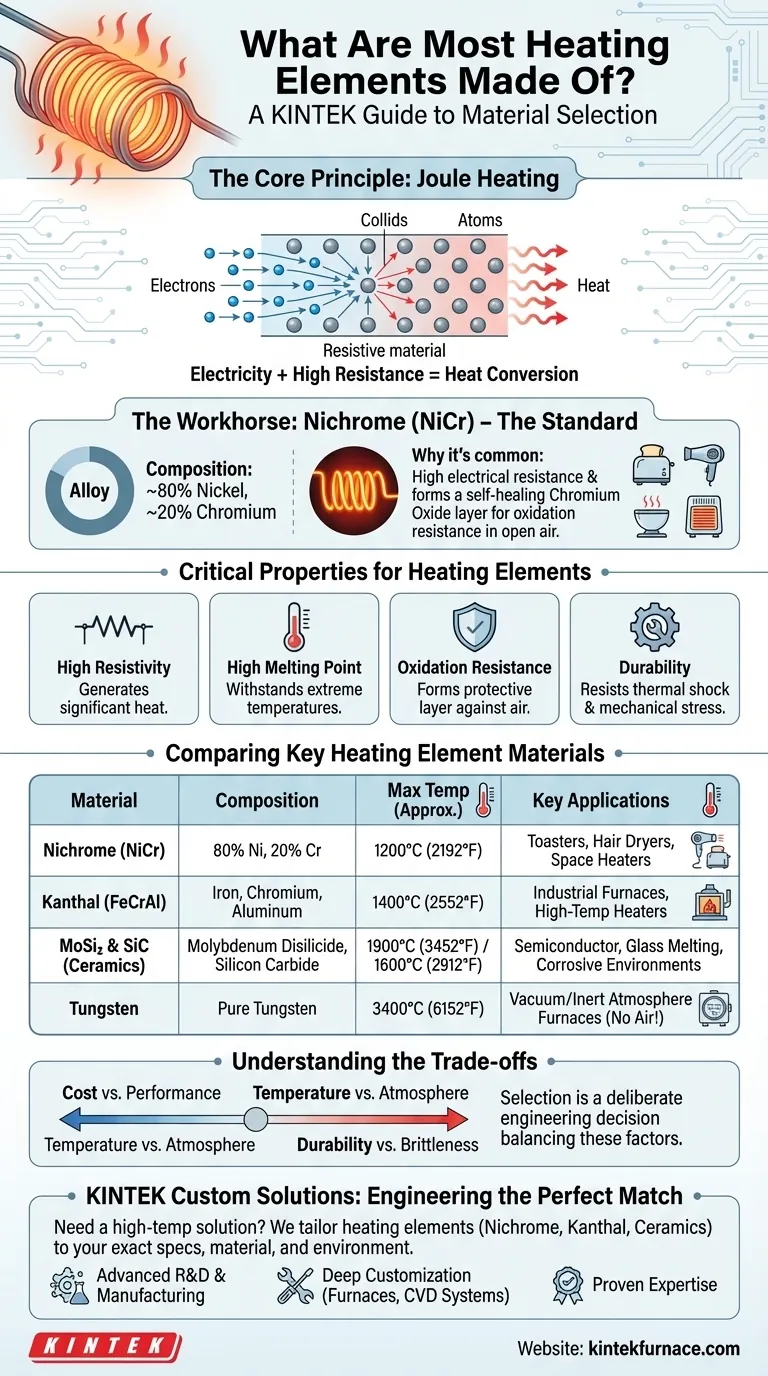

The Core Principle: How Resistive Heating Works

This section explains the fundamental physics and material properties that govern how heating elements function. Understanding these principles is key to seeing why certain materials are chosen over others.

Turning Electricity into Heat

At its core, a heating element is a resistor. When an electric current flows through a material with high electrical resistance, the moving electrons collide with the atoms of the material. These collisions convert electrical energy directly into thermal energy, or heat.

This phenomenon, known as Joule heating, is the simple and reliable principle behind everything from an electric toaster to an industrial furnace.

What Makes a Material a Good Heater?

Only a select few materials are suitable for use as heating elements. They must possess a specific combination of properties to function effectively and reliably.

- High Resistivity: The material must resist the flow of electricity enough to generate significant heat, but not so much that it acts as an insulator.

- High Melting Point: The element must operate at very high temperatures without melting or deforming.

- Resistance to Oxidation: This is critical. At high temperatures, many metals rapidly react with oxygen in the air, causing them to become brittle and fail. A good heating element forms a stable, protective outer layer that prevents this.

- Durability: The material should have minimal thermal expansion to avoid mechanical stress and cracking during repeated heating and cooling cycles.

The Workhorse Material: Nichrome (NiCr)

For most applications, one alloy stands out as the ideal intersection of all the necessary properties: Nichrome.

Why Nichrome Is So Common

Nichrome’s dominance comes from its uniquely balanced profile. Its high nickel and chromium content gives it the necessary electrical resistance to generate heat efficiently.

Crucially, when heated, the chromium on the surface forms a thin, stable layer of chromium oxide. This layer is self-healing, adheres strongly to the metal, and protects the underlying alloy from further oxidation, granting it a long service life in open air.

Typical Applications

Because of its excellent balance of cost, performance, and durability, Nichrome is the go-to material for a wide range of consumer and light industrial products. You will find it in toasters, hair dryers, space heaters, and many electric furnaces.

Exploring Other Key Materials

While Nichrome is the most common, different applications demand different materials, especially at the extremes of temperature and cost.

Kanthal (FeCrAl): The High-Temp, Lower-Cost Alternative

Kanthal is the brand name for a family of iron-chromium-aluminum alloys. It can withstand even higher temperatures than Nichrome and is often less expensive. It also forms a protective oxide layer (aluminum oxide) for durability.

However, it can be more brittle than Nichrome, making it less suitable for applications involving significant vibration or complex shapes. It is primarily used in high-temperature industrial heating elements and furnaces.

MoSi₂ and SiC: For Extreme Industrial Furnaces

For the most demanding industrial processes, metallic alloys reach their limits. Here, ceramics like Molybdenum Disilicide (MoSi₂) and Silicon Carbide (SiC) are used.

These materials can operate at extremely high temperatures (approaching 1900°C / 3450°F) and are highly resistant to corrosion. Their primary use is in specialized industrial furnaces for semiconductor manufacturing, glass melting, and material testing.

Tungsten: For Specialized Vacuum Environments

Tungsten has the highest melting point of any metal (3422°C / 6191°F), making it theoretically ideal for ultra-high-temperature heating.

However, tungsten oxidizes and fails almost instantly when heated in the presence of air. Therefore, its use as a heating element is restricted to vacuum furnaces or environments filled with an inert gas.

Understanding the Trade-offs

Selecting a heating element material is an exercise in managing competing priorities. There is no single perfect solution.

Cost vs. Performance

Kanthal (FeCrAl) alloys often provide better high-temperature performance at a lower cost than Nichrome. However, Nichrome's superior ductility and well-understood properties keep it the standard for many applications where manufacturing flexibility is key.

Temperature vs. Atmosphere

The operating environment is as important as the temperature. A material like Tungsten, which is superior at extreme temperatures, is completely useless in open air. Nichrome and Kanthal thrive precisely because their protective oxide layers allow them to operate reliably in a normal atmosphere.

Durability vs. Brittleness

Metal alloys like Nichrome are generally ductile and can be drawn into wires and coils easily. High-performance ceramics like Silicon Carbide, while incredibly heat-resistant, are far more brittle and must be handled and supported with care to prevent mechanical failure.

Selecting the Right Material for the Job

Your choice depends entirely on the specific requirements of the application.

- If your primary focus is everyday appliances: Nichrome is the standard due to its excellent balance of properties and durability in open air.

- If your primary focus is high-temperature industrial heating on a budget: Kanthal (FeCrAl) alloys offer a compelling performance-to-cost ratio.

- If your primary focus is extreme temperatures in controlled atmospheres: Molybdenum Disilicide, Silicon Carbide, or Tungsten are required for their superior melting points and stability.

Ultimately, the ideal heating element is a product of deliberate engineering, matching a material's unique properties to a specific thermal challenge.

Summary Table:

| Material | Key Composition | Max Temp (Approx.) | Key Applications |

|---|---|---|---|

| Nichrome (NiCr) | 80% Nickel, 20% Chromium | 1200°C (2192°F) | Toasters, Hair Dryers, Space Heaters |

| Kanthal (FeCrAl) | Iron, Chromium, Aluminum | 1400°C (2552°F) | Industrial Furnaces, High-Temp Heaters |

| Molybdenum Disilicide (MoSi₂) | Molybdenum, Silicon | 1900°C (3452°F) | Semiconductor, Glass Melting Furnaces |

| Silicon Carbide (SiC) | Silicon, Carbon | 1600°C (2912°F) | Corrosive Environments, Industrial Heating |

| Tungsten | Pure Tungsten | 3400°C (6152°F) | Vacuum/Inert Atmosphere Furnaces |

Need a Custom High-Temperature Heating Solution?

At KINTEK, we understand that selecting the right heating element is critical for your lab's performance. Whether you require the standard reliability of Nichrome, the high-temperature resilience of Kanthal, or the extreme heat capabilities of ceramic elements, our expertise ensures you get the perfect match for your application.

Why Choose KINTEK?

- Advanced R&D & Manufacturing: We develop and produce high-performance heating elements in-house, guaranteeing quality and consistency.

- Deep Customization: From Muffle and Tube Furnaces to complex CVD/PECVD Systems, we tailor heating solutions to your exact specifications, including material, geometry, and operating environment.

- Proven Expertise: We help laboratories across industries achieve precise, reliable, and efficient thermal processing.

Let's engineer the ideal heating solution for your unique requirements. Contact our experts today for a consultation!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability