The primary advantage of using a vacuum drying oven is the ability to evaporate moisture from deep within the activated carbon's pores at significantly reduced temperatures, typically around 70 °C. By lowering the ambient pressure, you decouple evaporation from high heat, effectively preventing the thermal destruction of organic functional groups and avoiding the collapse or blockage of the material's critical pore structure.

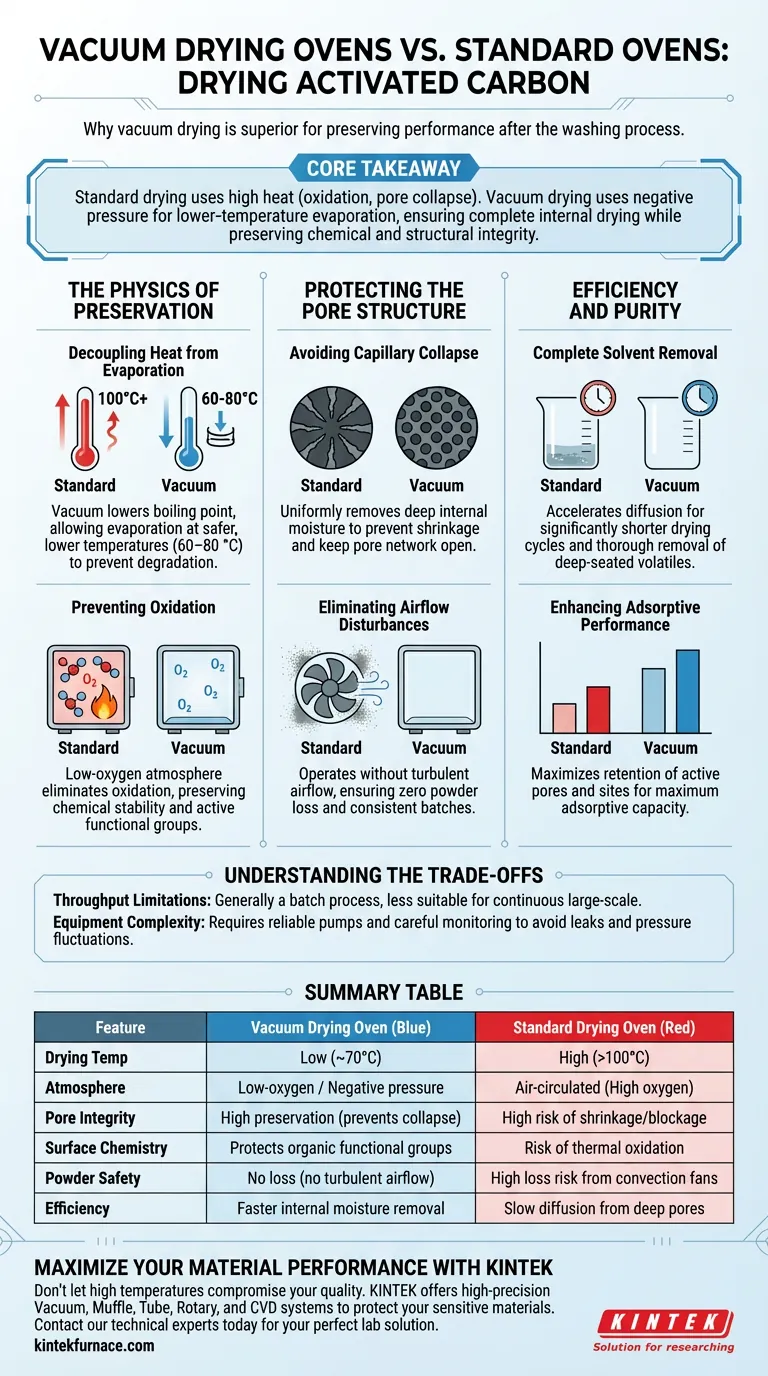

Core Takeaway Standard drying relies on high heat to drive out moisture, which risks oxidizing the carbon surface and collapsing the very pores you are trying to create. Vacuum drying utilizes negative pressure to lower the boiling point of water, ensuring complete internal drying while preserving the chemical and structural integrity of the activated carbon.

The Physics of Preservation

Decoupling Heat from Evaporation

In a standard oven, you must raise the temperature to 100 °C or higher to boil off water effectively. This high thermal load is often detrimental to porous carbon materials.

By reducing the pressure inside the chamber, a vacuum oven lowers the boiling point of water and residual solvents.

This allows rapid evaporation at much safer temperatures, typically between 60 °C and 80 °C, protecting the material from thermal degradation.

Preventing Oxidation

Activated carbon is sensitive to oxidation, particularly when wet and heated in the presence of air.

A standard oven circulates hot air, which supplies a constant stream of oxygen that can react with the carbon surface.

The vacuum environment creates a low-oxygen atmosphere, effectively eliminating oxidation reactions. This preserves the chemical stability of the surface and retains the active functional groups essential for adsorption.

Protecting the Pore Structure

Avoiding Capillary Collapse

Drying is not just about removing surface water; it is about emptying the internal microstructure.

Standard high-temperature drying can cause rapid evaporation at the surface, leading to "surface hardening" or crust formation. This traps moisture inside and can cause the internal pores to shrink or collapse due to capillary forces.

Vacuum drying pulls moisture from the deep internal pores uniformly. This prevents shrinkage and ensures the pore network remains open and accessible.

Eliminating Airflow Disturbances

Standard drying ovens often rely on convection (fans) to distribute heat.

For fine powders like activated carbon, forced air can cause powder loss or agglomeration.

Vacuum ovens operate without turbulent airflow. This ensures zero powder loss and prevents light particles from being blown around the chamber, maintaining the consistency of the batch.

Efficiency and Purity

Complete Solvent Removal

After washing, activated carbon may retain residual solvents or moisture deep within complex agglomerates.

Atmospheric drying often fails to remove these deep-seated volatiles without excessive heating times.

The negative pressure of a vacuum oven accelerates the diffusion of these molecules to the surface, significantly shortening the drying cycle while ensuring thorough removal.

Enhancing Adsorptive Performance

The ultimate goal of activated carbon is a high surface area for adsorption.

High-temperature atmospheric drying can destroy organic functional groups and block active pores, reducing the Effective Electrochemical Active Surface Area (ECSA).

By using vacuum drying, you maximize the retention of these sites, ensuring the final product maintains its maximum adsorptive capacity.

Understanding the Trade-offs

Throughput Limitations

While vacuum drying offers superior quality, it is generally a batch process.

It may not match the continuous throughput capabilities of large-scale industrial conveyor dryers used for lower-grade materials.

Equipment Complexity

Vacuum ovens require a reliable pump system and seals.

You must monitor the vacuum levels carefully; a leak can lead to pressure fluctuations that disrupt the drying profile or reintroduce oxygen.

Making the Right Choice for Your Goal

To determine if vacuum drying is strictly necessary for your specific batch, consider your performance targets:

- If your primary focus is preserving maximum surface area: Vacuum drying is non-negotiable to prevent pore shrinkage and collapse.

- If your primary focus is surface chemistry and functional groups: Use vacuum drying to eliminate oxygen and prevent thermal oxidation of specific organic sites.

- If your primary focus is bulk drying of coarse, low-grade carbon: A standard convection oven may suffice, provided the temperature is carefully controlled.

Vacuum drying is the only method that guarantees the structural and chemical fidelity of high-performance activated carbon.

Summary Table:

| Feature | Vacuum Drying Oven | Standard Drying Oven |

|---|---|---|

| Drying Temp | Low (approx. 70°C) | High (>100°C) |

| Atmosphere | Low-oxygen / Negative pressure | Air-circulated (High oxygen) |

| Pore Integrity | High preservation (prevents collapse) | High risk of shrinkage/blockage |

| Surface Chemistry | Protects organic functional groups | Risk of thermal oxidation |

| Powder Safety | No loss (no turbulent airflow) | High loss risk from convection fans |

| Efficiency | Faster internal moisture removal | Slow diffusion from deep pores |

Maximize Your Material Performance with KINTEK

Don't let high temperatures compromise your research or production quality. Backed by expert R&D and manufacturing, KINTEK offers high-precision Vacuum, Muffle, Tube, Rotary, and CVD systems designed to protect your sensitive materials. Whether you are processing activated carbon or advanced ceramics, our customizable lab high-temperature furnaces ensure structural integrity and chemical purity every time.

Ready to upgrade your drying process? Contact our technical experts today to find the perfect solution for your unique laboratory needs.

Visual Guide

References

- Kyfti Yolanda Siburian, Agung Nugroho. Effect of CoO loading on electrochemical properties of activated carbon from sugarcane bagasse. DOI: 10.5599/jese.2439

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How is forced cooling achieved in hot wall vacuum furnaces? Optimize Metallurgical Properties with Precision Cooling

- What are the typical components of a vacuum system used in a high-temperature distillation furnace? Ensure Process Precision

- What technical advantages do vacuum drying ovens offer for NH2-MIL-125? Preserve MOF Integrity with Precision Drying

- What are the advantages of vacuum carburizing over conventional atmosphere-carburizing methods? Boost Quality and Efficiency in Case Hardening

- What is the function of a high-pressure stainless steel autoclave in hydrothermal carbonization? Unlock Superior Carbon

- What role does a vacuum oven play in electrode prep? Optimize Lithium-Ion Battery Performance and Adhesion

- Which materials are suitable for a double-chamber oil quenching air-cooled vacuum furnace? Ideal for Alloy Steels

- What is a vacuum furnace and how does it function? Achieve Superior Material Purity and Performance