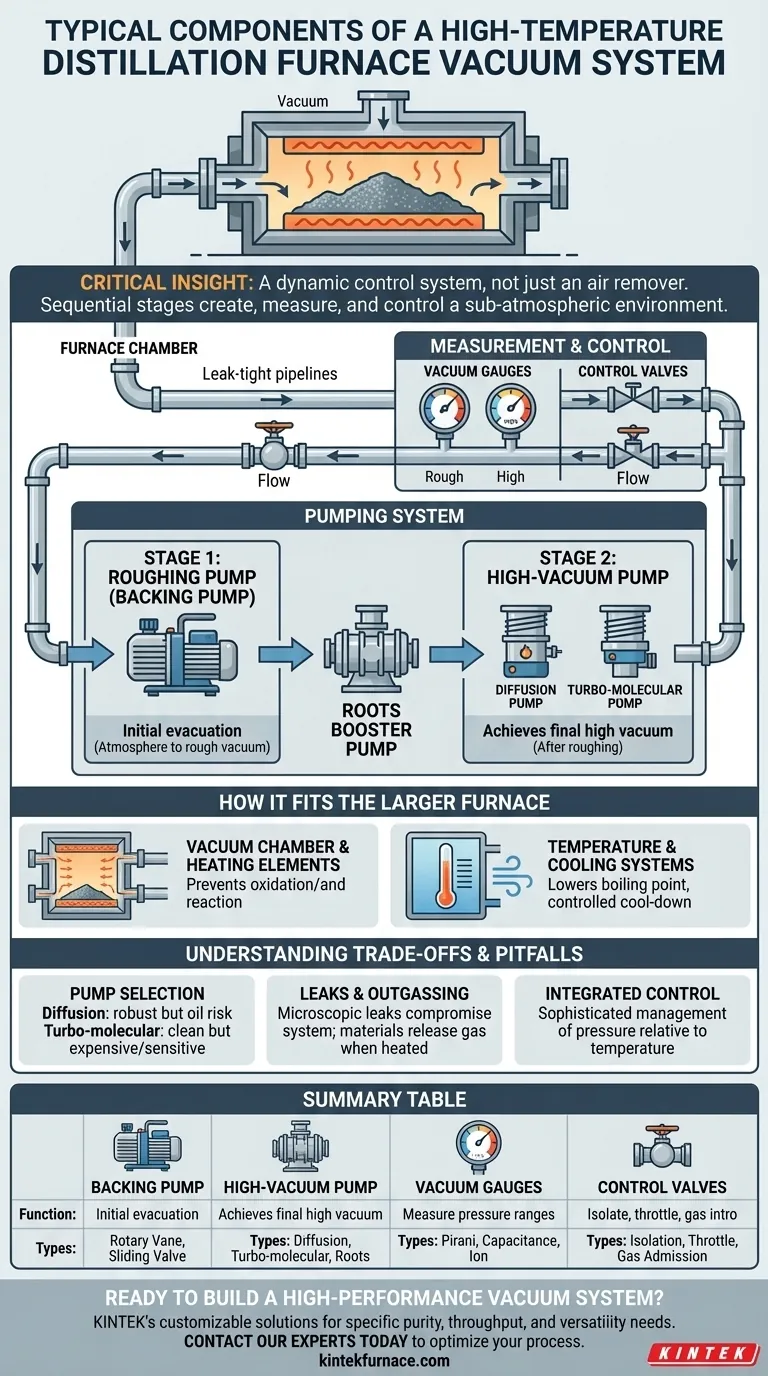

At its core, a complete vacuum system for a high-temperature distillation furnace is a multi-stage assembly designed to create, measure, and control a sub-atmospheric environment. The primary components are a vacuum pump set, which almost always includes both a backing pump and a high-vacuum pump, vacuum gauges to monitor pressure, and a series of control valves to manage the process. These elements are connected by leak-tight pipelines to the furnace chamber itself.

The critical insight is that a furnace vacuum system doesn't just remove air; it's a dynamic control system. Each component plays a sequential role, first creating a rough vacuum and then a high vacuum, allowing for precise management of the low-pressure environment essential for high-temperature distillation.

The Anatomy of a Furnace Vacuum System

A vacuum system's primary function is to evacuate the furnace chamber in stages. It must first remove the bulk of the air and then continue to pump out residual and released gases to reach and maintain the extremely low pressures required for distillation.

The Pumping System: The Engine of the Vacuum

The heart of any vacuum system is its set of pumps, which typically work in a two-stage process to efficiently reach the target pressure.

- The Backing Pump (Roughing Pump): This is the workhorse pump that does the initial "heavy lifting." It removes the vast majority of air from the furnace chamber, taking it from atmospheric pressure down to a rough vacuum level. Common types include rotary vane and sliding valve pumps.

- The High-Vacuum Pump: This pump cannot operate at atmospheric pressure and only kicks in after the backing pump has done its job. It takes the pressure from a rough vacuum down to the final high-vacuum level needed for the process. Common types include Roots pumps (often used as a booster), diffusion pumps, or turbo-molecular pumps.

Measurement and Control: The Brains of the Operation

Creating a vacuum is useless without the ability to measure and control it. These components ensure the process is precise, repeatable, and safe.

- Vacuum Gauges: These are the sensors that provide continuous, real-time measurement of the pressure inside the furnace chamber. Different types of gauges are used to accurately measure different vacuum ranges, from rough to high vacuum.

- Control Valves: These components act as the gates within the vacuum plumbing. They are used to isolate the furnace chamber from the pumps, throttle the pumping speed, or allow for the controlled introduction of inert gases.

How the Vacuum System Fits into the Larger Furnace

The vacuum system is a critical subsystem that enables the proper function of the entire furnace assembly. It works in direct concert with the heating, control, and cooling systems.

The Vacuum Chamber and Heating Elements

The vacuum chamber (or furnace body) is the sealed vessel where the distillation occurs. The vacuum created within it is essential for two reasons: it prevents the high-temperature heating elements (like graphite) from oxidizing and burning out, and it prevents the material being processed from reacting with air.

Temperature and Cooling Systems

The temperature control system, typically using thermocouples and controllers, works alongside the vacuum system. By lowering the pressure, the vacuum system lowers the boiling point of materials, allowing distillation to occur at more manageable temperatures. Similarly, the cooling system often operates under vacuum or a controlled inert atmosphere to achieve specific material properties during the cool-down phase.

Understanding the Trade-offs and Pitfalls

Designing and operating a vacuum system involves balancing performance, cost, and complexity. Misunderstanding these trade-offs can lead to failed processes.

Pump Selection is Critical

The choice of high-vacuum pump has significant consequences. A diffusion pump is robust and cost-effective but uses oil, which creates a small risk of contaminating the furnace chamber (known as "backstreaming"). An oil-free turbo-molecular pump offers a cleaner vacuum but is more expensive and sensitive to mechanical shock.

The Constant Battle: Leaks and Outgassing

A vacuum system is only as good as its seals. Even a microscopic leak can prevent the system from reaching its target pressure, compromising the entire distillation process. Furthermore, materials inside the furnace (including the material being processed) will release trapped gases and moisture when heated under vacuum, a phenomenon called outgassing. The vacuum system must be powerful enough to overcome both leaks and outgassing to maintain the desired pressure.

The Complexity of Integrated Control

Achieving a successful distillation requires a sophisticated control system that manages the interplay between temperature ramps and vacuum levels. It is not a simple "on/off" operation; it's a carefully orchestrated sequence where pressure must be precisely managed relative to temperature to achieve the desired outcome.

How to Apply This to Your Project

Your choice of components should be directly driven by the specific requirements of your distillation process.

- If your primary focus is ultimate purity: Prioritize an oil-free high-vacuum pump (like a turbo-molecular pump) to eliminate any risk of hydrocarbon contamination.

- If your primary focus is high throughput and speed: A large backing pump paired with a Roots booster pump provides very fast pump-down times for industrial-scale operations.

- If your primary focus is process versatility: Invest in an advanced control system with high-precision gauges and automated valves to handle a wide range of materials and distillation profiles.

By understanding how these core components function and interact, you can ensure your vacuum system provides the precise environmental control necessary for successful material transformation.

Summary Table:

| Component | Primary Function | Key Types |

|---|---|---|

| Backing Pump | Initial evacuation from atmosphere to rough vacuum | Rotary Vane, Sliding Valve |

| High-Vacuum Pump | Achieves final high vacuum for the process | Diffusion, Turbo-molecular, Roots Booster |

| Vacuum Gauges | Measure pressure across different vacuum ranges | Pirani, Capacitance Manometer, Ion Gauge |

| Control Valves | Isolate, throttle flow, and manage gas introduction | Isolation, Throttle, Gas Admission Valves |

Ready to build a high-performance vacuum system for your high-temperature distillation process? KINTEK's advanced high-temperature furnaces, including our customizable Vacuum & Atmosphere models, are engineered for precision. Leveraging our exceptional R&D and in-house manufacturing, we provide robust solutions with integrated vacuum systems tailored to your specific purity, throughput, and versatility needs. Contact our experts today to discuss how we can optimize your material transformation process.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion