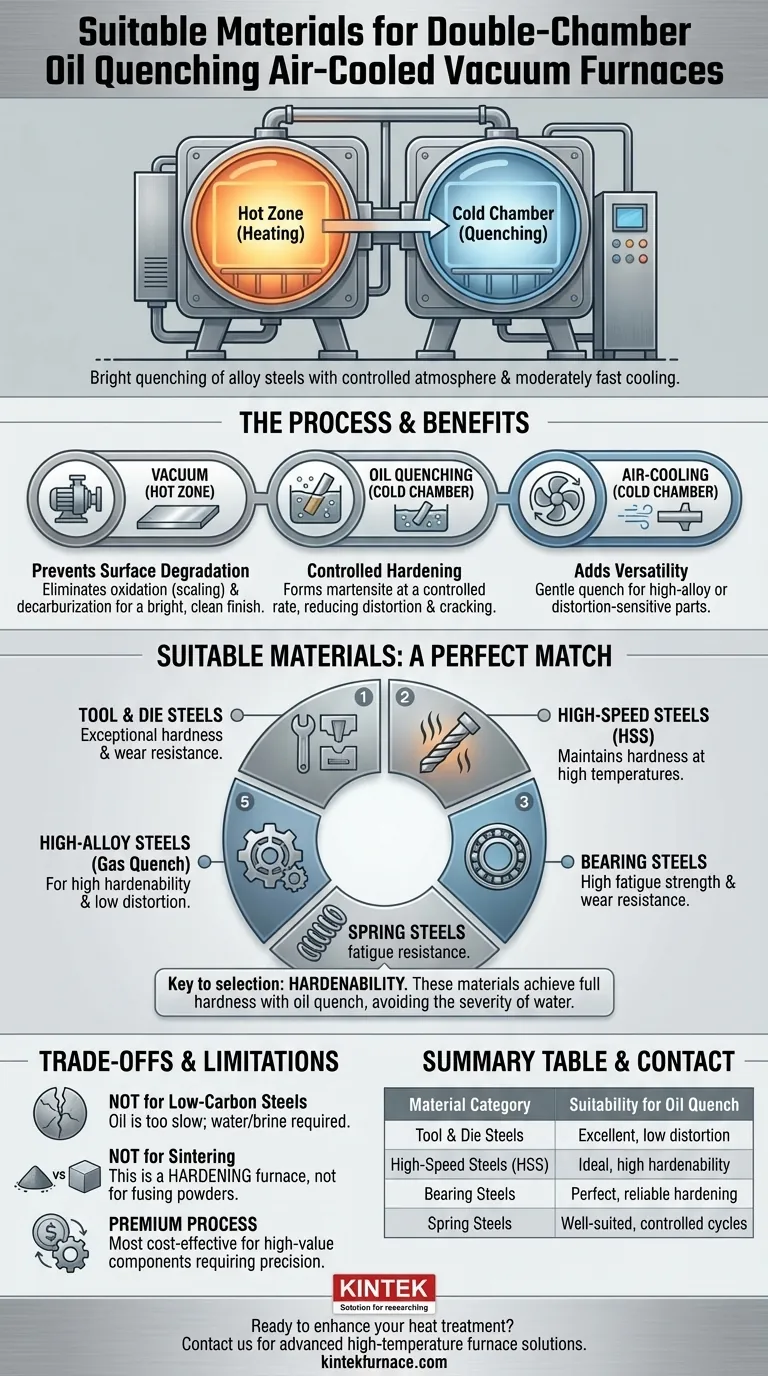

In short, a double-chamber oil quenching air-cooled vacuum furnace is specifically designed for the bright quenching of alloy steels that require a controlled atmosphere and a moderately fast cooling rate. The most suitable materials include tool steel, die steel, high-speed steel, bearing steel, and spring steel.

The key to selecting the right material is understanding its hardenability. This furnace is ideal for steels that can achieve full hardness with an oil quench, which is faster than air but less severe than water, all while using a vacuum to prevent surface oxidation and decarburization.

Why These Materials Are a Perfect Match

A double-chamber vacuum furnace offers distinct stages—a hot zone for heating and a separate cold chamber for quenching. This design provides precise control over the entire heat treatment cycle, which is critical for high-performance steels.

The Role of Vacuum: Preventing Surface Degradation

The primary purpose of using a vacuum is to create a pure, controlled atmosphere. When steel is heated, it readily reacts with oxygen in the air.

This process, called oxidation (scaling) and decarburization (loss of surface carbon), ruins the part's surface finish and compromises its mechanical properties.

A vacuum environment eliminates these reactions, resulting in a clean, scale-free, or "bright" surface finish straight out of the furnace. This often reduces or eliminates the need for post-treatment cleaning or machining.

The Science of Oil Quenching: Controlled Hardening

Hardening steel involves heating it to a critical temperature (austenitizing) and then cooling it rapidly enough to transform its internal structure into martensite, a very hard and brittle phase.

The "critical cooling rate" is the minimum speed required to achieve this transformation. Materials like high-carbon and alloy steels have good hardenability, meaning they don't require an extremely fast quench.

Oil provides a cooling rate that is ideal for these steels. It is fast enough to form martensite but slower and less severe than water, significantly reducing the risk of distortion or cracking in complex or high-value parts.

The Air-Cooling Function: Adding Versatility

The air-cooling (or gas quenching) capability makes the furnace highly versatile. Some high-alloy steels, like certain grades of high-speed steel or hot-work die steels, can be hardened effectively with a rapid flow of inert gas.

This provides an even gentler quench than oil, making it suitable for extremely distortion-sensitive components or materials with very high hardenability.

A Closer Look at Suitable Steel Categories

The suitability of a material is directly tied to its composition and intended application.

Tool & Die Steels

This category includes high-carbon and high-chromium steels. They are chosen for their exceptional hardness, wear resistance, and ability to hold a cutting edge. Oil quenching provides the necessary hardness without the high risk of fracture associated with water quenching.

High-Speed Steels (HSS)

High-speed steels are designed to maintain their hardness even at the elevated temperatures generated by cutting operations. Their high alloy content gives them excellent hardenability, making them perfectly suited for either oil or gas quenching in a vacuum furnace.

Bearing & Spring Steels

These steels require a unique combination of high hardness, wear resistance, and exceptional fatigue strength. The precise, repeatable control offered by a vacuum furnace with an oil quench ensures these materials achieve the ideal microstructure for reliability under cyclic loads.

Understanding the Trade-offs and Limitations

While powerful, this type of furnace is not a universal solution. Its effectiveness is tied to using it for the right materials and processes.

The Quenching Rate Is Specific

This furnace is not suitable for plain low-carbon steels or shallow-hardening alloys that require the extremely rapid cooling rate of water or brine to achieve full hardness. Using oil on these materials will result in a soft part with poor mechanical properties.

This Is a Hardening Furnace, Not a Sintering Furnace

Do not confuse a vacuum quenching furnace with a vacuum sintering furnace. While both use a vacuum, their functions are fundamentally different. Sintering involves fusing powders (like ceramics or metal injection molded parts) at high temperatures. A quenching furnace is designed to heat and rapidly cool solid metal parts to alter their properties.

Precision Comes at a Cost

Vacuum heat treatment is a premium process. It is most cost-effective for high-value components where a bright finish, minimal distortion, and repeatable properties are critical. For simple parts made from materials that don't require a vacuum, a less expensive atmospheric furnace may be more appropriate.

Making the Right Choice for Your Application

Selecting the correct material and process is essential for achieving your desired outcome. Use the furnace's capabilities to match the material's requirements.

- If your primary focus is maximum hardness and wear resistance for tools or dies: High-carbon tool steels (like D2) and high-speed steels (like M2) are ideal candidates for the oil quench.

- If your primary focus is fatigue life and durability for moving parts: Bearing steels (like 52100) and spring steels are perfectly suited for the repeatable results of a vacuum oil quench.

- If your primary focus is hardening highly alloyed, distortion-sensitive parts: Consider using the furnace's gas or air-cooling function as a gentler alternative for materials with sufficient hardenability.

Ultimately, successful heat treatment comes from precisely matching the material's metallurgical needs with the specific capabilities of your furnace.

Summary Table:

| Material Category | Key Characteristics | Suitability for Oil Quench |

|---|---|---|

| Tool & Die Steels | High hardness, wear resistance | Excellent for achieving full hardness with low distortion |

| High-Speed Steels | Maintains hardness at high temperatures | Ideal due to high hardenability |

| Bearing Steels | High fatigue strength, wear resistance | Perfect for reliable, repeatable hardening |

| Spring Steels | Exceptional fatigue resistance | Well-suited for controlled quenching cycles |

Ready to enhance your heat treatment process with precision and reliability? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet the unique experimental requirements of laboratories working with alloy steels like tool, die, high-speed, bearing, and spring steels. Contact us today via our contact form to discuss how our vacuum furnaces can deliver bright, oxidation-free results and superior performance for your high-value components!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance