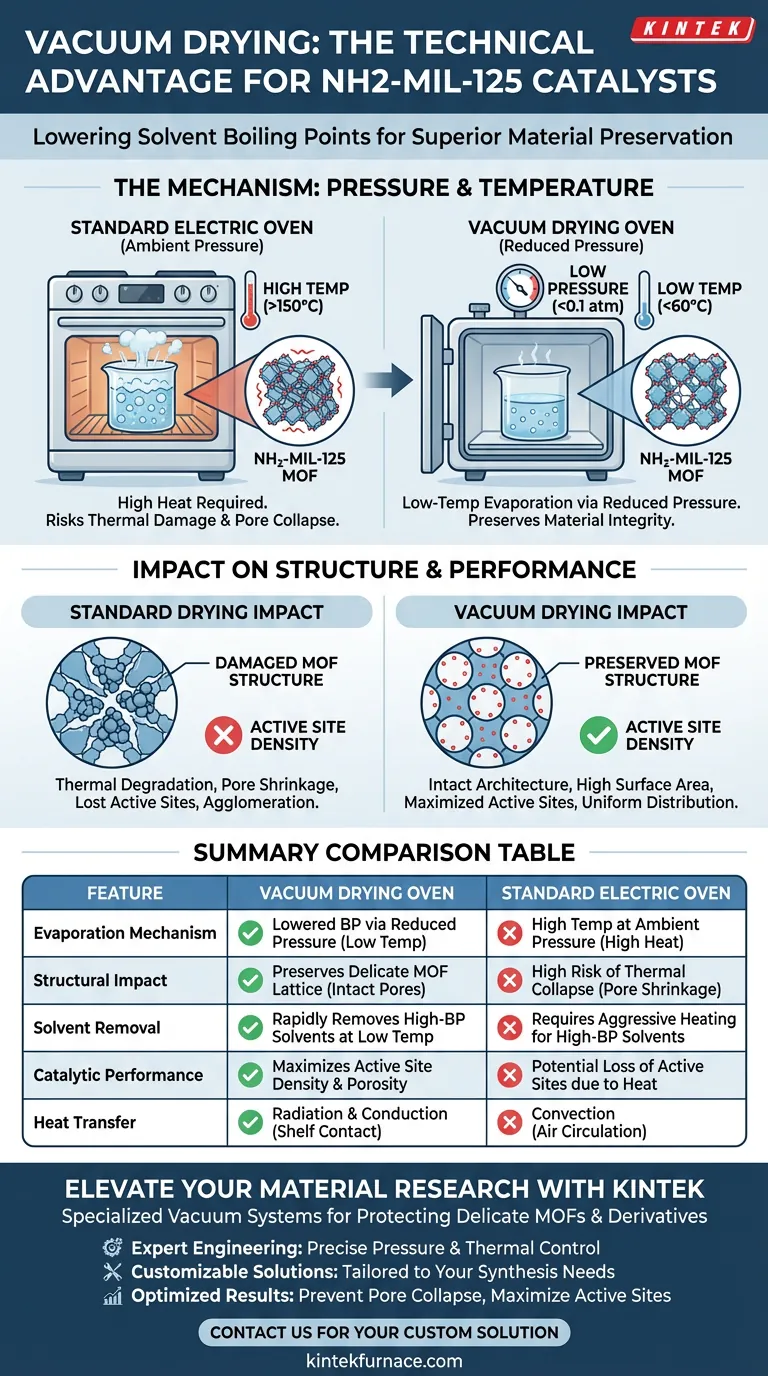

Vacuum drying ovens provide a critical advantage over standard electric ovens by lowering the boiling point of solvents through reduced pressure. This technical capability allows for the rapid evaporation of high-boiling solvents like dimethylformamide (DMF) at significantly lower temperatures, preventing thermal damage to the material.

Core Takeaway Processing NH2-MIL-125 requires the removal of stubborn solvents without subjecting the delicate Metal-Organic Framework (MOF) to destructive heat. Vacuum drying decouples temperature from evaporation, ensuring the preservation of the catalyst's porous architecture and active site density, which are directly correlated to catalytic performance.

The Mechanism of Low-Temperature Evaporation

Overcoming High Boiling Points

Standard electric ovens rely on ambient pressure, requiring temperatures to exceed a solvent's boiling point for efficient removal. Solvents commonly used in NH2-MIL-125 synthesis, such as dimethylformamide (DMF), have high boiling points that necessitate aggressive heating in a standard environment.

The Vacuum Advantage

By reducing the ambient pressure, vacuum ovens significantly lower the boiling threshold of these solvents. This allows residual DMF and ethanol to evaporate rapidly at much cooler temperatures. You achieve thorough solvent removal without ever reaching the thermal thresholds that endanger the material.

Preserving Structural Integrity

Protecting the MOF Architecture

NH2-MIL-125 is a delicate metal-organic framework. Exposure to the high temperatures required by standard ovens can cause the collapse of its intricate crystal lattice. Vacuum drying mitigates this risk entirely by keeping the thermal load minimal.

Maintaining Porosity in Derivatives

For derivatives like N-doped TiO2@C, the porous structure is essential for functionality. Standard high-heat drying can induce thermal degradation that shrinks or closes these pores. Vacuum processing ensures the high specific surface area is retained, keeping the material open and accessible for chemical reactions.

Impact on Catalytic Activity

Active Site Conservation

The catalytic power of NH2-MIL-125 depends on the availability of its active sites. High heat can denature or obscure these sites. By utilizing a low-temperature vacuum process, you ensure the active site integrity remains uncompromised.

Preventing Agglomeration

While standard drying can lead to particle migration or clumping due to thermal effects, vacuum drying stabilizes the material structure. This results in a more uniform distribution of the catalyst, maximizing its electrochemical or photochemical efficiency.

Understanding the Trade-offs

Equipment Complexity and Cost

Vacuum drying systems are inherently more complex than standard convection ovens. They require a reliable vacuum pump, distinct seals, and regular maintenance to ensure pressure stability. This increases both the initial capital investment and operational overhead.

Throughput Limitations

Vacuum ovens typically offer smaller chamber capacities compared to industrial standard electric ovens. Furthermore, the heat transfer in a vacuum is primarily radiative or conductive (via shelf contact), which can sometimes lead to uneven drying if the samples are not layered correctly.

Making the Right Choice for Your Goal

To maximize the performance of your NH2-MIL-125 and derivative catalysts, align your drying method with your specific processing needs:

- If your primary focus is maximizing surface area and catalytic activity: Use a vacuum drying oven to remove DMF and ethanol at low temperatures, preventing pore collapse and preserving active sites.

- If your primary focus is bulk drying of non-sensitive precursor materials: A standard electric oven may be sufficient, provided the materials are thermally stable and high-boiling solvents are not present.

The integrity of your final catalyst is determined not just by how you synthesize it, but by how gently you remove the solvent.

Summary Table:

| Feature | Vacuum Drying Oven | Standard Electric Oven |

|---|---|---|

| Evaporation Mechanism | Lowered boiling point via reduced pressure | High temperature at ambient pressure |

| Structural Impact | Preserves delicate MOF crystal lattice | High risk of thermal collapse/pore shrinkage |

| Solvent Removal | Rapidly removes DMF at low temperatures | Requires high heat for high-boiling solvents |

| Catalytic Performance | Maximizes active site density/porosity | Potential loss of active sites due to heat |

| Heat Transfer | Radiation & Conduction | Convection |

Elevate Your Material Research with KINTEK

Don't let aggressive heating compromise your delicate NH2-MIL-125 architectures. KINTEK provides industry-leading vacuum drying systems designed specifically to protect the integrity of Metal-Organic Frameworks and their derivatives.

Our value to you:

- Expert Engineering: Backed by professional R&D and manufacturing, our systems ensure precise pressure control and uniform thermal management.

- Customizable Solutions: Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, we tailor our high-temp lab furnaces to your unique catalytic synthesis requirements.

- Optimized Results: Prevent pore collapse and maintain maximum active site density in your N-doped TiO2@C and other advanced materials.

Ready to achieve superior catalyst performance? Contact us today to find your custom solution!

Visual Guide

References

- Wenbin Wang, Dongping Sun. NH2-MIL-125-Derived N-Doped TiO2@C Visible Light Catalyst for Wastewater Treatment. DOI: 10.3390/polym16020186

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What safety concerns are mentioned regarding the vacuum chamber? Avoid Catastrophic Implosion Risks

- What are the different heating methods in vacuum sintering furnaces? Choose the Best for Your Materials

- Why is a high vacuum environment necessary during the SPS of CoCrFeMnNi alloy powders? Ensure Purity and Density

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What are the essential requirements for a high-temperature vacuum furnace? Optimize Your Metal Solidification Research

- What are the key indicators for measuring the performance of vacuum heat treatment equipment? Optimize Your Process with KINTEK

- What are refractory metals and which one is most commonly used for heating elements in vacuum furnaces? Molybdenum is the top choice for its balance of performance and cost.

- Is vacuum brazing better than brazing? Unlock Superior Joint Quality for Critical Applications