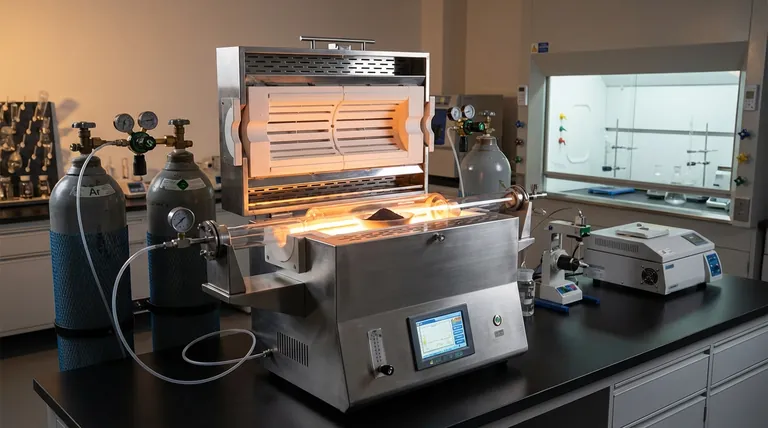

Atmosphere control within a tube furnace is the single most critical variable for synthesizing high-purity Cobalt Sulfide and Carbon Nanotube (Co1-xS@CNT) composites. It ensures phase purity by maintaining a sealed, inert environment—typically using flowing Argon—which simultaneously prevents the combustion of the carbon backbone and eliminates oxygen that would otherwise contaminate the metal sulfide phase.

Core Takeaway A tube furnace guarantees phase purity by creating a sealed ecosystem where inert gas flow excludes atmospheric oxygen. This protects the structural integrity of Carbon Nanotubes at high temperatures while forcing the Cobalt precursor to undergo complete sulfidation rather than oxidation.

The Mechanics of Phase Purity

Preserving the Carbon Backbone

At the high temperatures required for synthesis (often around 500–600°C), carbon nanotubes are highly susceptible to oxidation. Without a strictly controlled atmosphere, the carbon structural components would react with oxygen and burn off as CO2.

The tube furnace provides a continuous flow of inert gas, such as Argon. This blankets the material, ensuring the Carbon Nanotubes remain intact to serve as the conductive framework for the composite.

Preventing Oxide Contamination

To achieve the pure Cobalt Sulfide (Co1-xS) phase, you must suppress the formation of unwanted metal oxides. In an uncontrolled environment, Cobalt prefers to bond with oxygen.

By sealing the reaction chamber and purging it with inert gas, the furnace removes competitive oxidizers. This forces the Cobalt to react exclusively with the sulfur source, ensuring the final product is a pure sulfide rather than a mixed oxide-sulfide hybrid.

Facilitating Uniform Sulfidation

The conversion from the precursor (typically Co3O4) to Cobalt Sulfide is a gas-solid reaction. The furnace heats sulfur until it sublimates into a vapor.

The controlled atmosphere allows this sulfur vapor to flow uniformly over the solid Cobalt-CNT precursor. This precise regulation ensures the chemical conversion is complete throughout the entire material, not just on the surface.

Critical Process Controls

The Necessity of Sealing

Gas flow alone is insufficient if the system is not hermetically sealed. Even microscopic leaks can introduce enough atmospheric oxygen to ruin phase purity.

Proper sealing creates a closed loop where the partial pressure of oxygen is effectively zero. This is non-negotiable for preventing the re-oxidation of the Cobalt species during the heating or cooling stages.

Regulation of Gas Flow

The rate of inert gas flow plays a dual role: it acts as a carrier and a barrier.

It carries the sublimated sulfur to the reaction site while simultaneously flushing out any volatile byproducts. Precise flow control ensures the reduction and sulfidation environment remains stable for the duration of the synthesis.

Common Pitfalls and Trade-offs

The Risk of "Dead Zones"

While tube furnaces differ from vacuum furnaces, flow dynamics are still critical. If the gas flow is too low, "dead zones" may occur where sulfur vapor does not penetrate the CNT network.

This results in a composite where the core remains unreacted (oxide) while the shell is converted to sulfide, degrading the material's electrochemical performance.

Over-Flowing the System

Conversely, an excessively high flow rate can "sweep" the sulfur vapor away too quickly.

This reduces the contact time between the sulfur gas and the cobalt precursor. The trade-off requires balancing flow speed to maintain an inert environment without diluting the reactant concentration.

Making the Right Choice for Your Goal

To maximize the quality of your Co1-xS@CNT composites, you must tailor your atmosphere control strategy to your specific performance metrics.

- If your primary focus is Electrical Conductivity: Prioritize the purity of the Argon source and seal integrity to ensure zero degradation of the Carbon Nanotube network.

- If your primary focus is High Specific Capacity: Focus on optimizing the residence time of the gas flow to ensure complete chemical conversion from Cobalt Oxide to Cobalt Sulfide.

Success in this synthesis relies not just on temperature, but on the absolute exclusion of oxygen to force the desired chemical pathway.

Summary Table:

| Variable | Function in Co1-xS@CNT Synthesis | Impact on Phase Purity |

|---|---|---|

| Inert Gas (Argon) | Prevents combustion of Carbon Nanotubes | Maintains conductive carbon framework |

| Hermetic Sealing | Excludes atmospheric oxygen/moisture | Prevents unwanted Cobalt Oxide formation |

| Sulfur Vapor Flow | Facilitates gas-solid reaction | Ensures uniform and complete sulfidation |

| Flow Rate Control | Balances reactant contact time | Eliminates unreacted "dead zones" in the material |

Achieve Unmatched Material Purity with KINTEK

Precise atmosphere control is the difference between a high-performance composite and a failed batch. KINTEK provides industry-leading Tube, Vacuum, and CVD systems engineered specifically for rigorous R&D and advanced manufacturing requirements.

Our customizable high-temperature furnaces offer the hermetic sealing and gas-flow precision necessary to protect sensitive Carbon Nanotubes and ensure the complete sulfidation of Cobalt precursors.

Ready to optimize your synthesis process? Contact our expert team today to find the perfect furnace solution for your unique laboratory needs.

References

- Changwei Shan, Liwei Mi. Co<sub>1−<i>x</i></sub>S@CNT composite with a three-dimensional skeleton for high-performance magnesium–lithium hybrid batteries. DOI: 10.1039/d3ma01089a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- Why is a high-precision annealing furnace necessary for optical fibers? Control Nanoparticle Growth for Peak Performance

- What kind of atmosphere is typically used in low vacuum atmosphere furnaces? Optimize Your Heat Treatment with Inert Gases

- Why is a high-purity argon atmosphere necessary during the mechanical alloying of aluminum matrix composites?

- Why must NaFePO4 carbonization be in an inert atmosphere furnace? Ensure High Conductivity and Material Stability

- What is the relationship between temperature and furnace atmosphere effectiveness? Master Heat Treatment Control

- Why must a high-purity argon protective atmosphere be maintained during mechanical alloying? Ensure Peak Material Purity

- What are some common applications of retort furnaces? Essential for Controlled Atmosphere Heat Treatment

- What is an atmospheric furnace? Understand the Risks & Efficiency of Your Home Heating