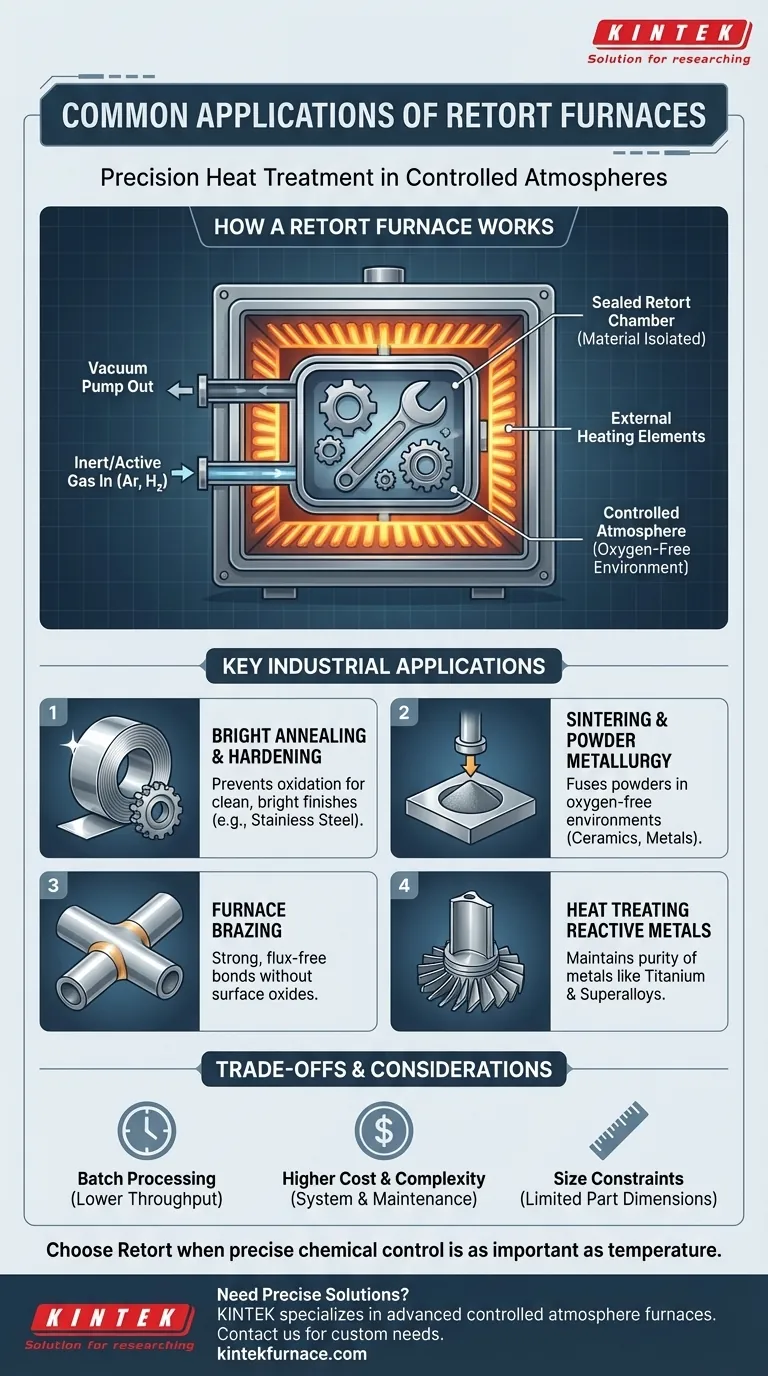

In short, retort furnaces are used for heat treatment processes where controlling the atmosphere is critical to the outcome. Their most common applications include the bright annealing of stainless steel, heat treating reactive metals like titanium, furnace brazing, and the sintering of powdered metals and ceramics. These processes require an environment free of oxygen to prevent oxidation and ensure material purity and integrity.

The defining feature of a retort furnace is not just its ability to get hot, but its ability to create a chemically controlled environment. It isolates the material inside a sealed container (the retort), allowing for processes that would be impossible in open air.

What Makes a Retort Furnace Unique?

A retort furnace isn't just a hot box; it's a high-precision tool. Its design is centered around a crucial component: the retort.

The Core Concept: A Sealed Chamber

The retort is a sealed, gas-tight container, typically made of high-temperature metal alloys or ceramic, that holds the material being processed.

This container is placed inside the furnace, which heats the retort from the outside. The material, therefore, is never directly exposed to the furnace's heating elements or the outside air.

The Power of a Controlled Atmosphere

This separation is the key. The air inside the retort can be pumped out to create a vacuum, or it can be replaced with a specific gas.

This controlled atmosphere is fundamental. Using inert gases like argon prevents chemical reactions, while using active gases like hydrogen can actively clean parts by reducing surface oxides. This is what enables processes like "bright annealing."

Key Industrial Applications

The ability to control the process atmosphere makes retort furnaces essential in metallurgy and advanced manufacturing.

Bright Annealing and Hardening

When steel is heated in air, it oxidizes, creating a dark, scaled surface. Bright annealing is a process that softens the metal without causing this discoloration.

By performing the annealing in a retort filled with an inert or reducing atmosphere, parts emerge from the furnace clean and "bright," eliminating the need for post-process cleaning. This is critical for stainless steel parts.

Sintering and Powder Metallurgy

Sintering is a process that fuses fine powders into a solid mass using heat, but without melting them. This is the basis of powder metallurgy and is used to make many ceramic and metal parts.

The vast surface area of fine powders makes them extremely reactive to oxygen. A retort furnace provides the necessary oxygen-free environment to successfully sinter these materials.

Furnace Brazing

Brazing joins two metal components using a filler metal that melts at a lower temperature than the base parts.

Performing this in a retort furnace under a vacuum or controlled atmosphere prevents oxides from forming on the joint surfaces. This results in a stronger, cleaner, and more reliable bond without the need for corrosive chemical fluxes.

Heat Treating Reactive Metals

Metals like titanium and certain superalloys are highly reactive with oxygen, nitrogen, and hydrogen at high temperatures.

Processing these materials in a retort furnace is often the only way to perform heat treatment without contaminating the metal and compromising its mechanical properties.

Understanding the Trade-offs

While powerful, a retort furnace is not the solution for every heating application. Objectivity requires acknowledging its limitations.

Batch Processing vs. Continuous Flow

Most retort furnaces operate in a batch process. You load the retort, run the cycle, cool it, and unload it. This is less efficient for extremely high-volume production compared to continuous belt furnaces.

Higher Cost and Complexity

The retort itself, along with the vacuum pumps and gas management systems, adds significant cost and complexity compared to a simple furnace that just heats in ambient air. Maintenance of the seals and retort integrity is critical.

Size and Throughput Constraints

The physical size of the retort limits the dimensions of the parts that can be processed. The need to heat and cool the entire retort vessel for each batch can also lead to longer overall cycle times.

Making the Right Choice for Your Goal

Selecting the correct thermal processing equipment depends entirely on the material requirements and your desired outcome.

- If your primary focus is preventing any surface oxidation: A retort furnace is the definitive choice for processing stainless steel, copper alloys, or any part where a clean, bright finish is required.

- If your primary focus is processing reactive metals or powders: The controlled atmosphere of a retort furnace is non-negotiable for materials like titanium, superalloys, and for all powder metallurgy or sintering.

- If your primary focus is simple heating where oxidation is acceptable: For applications like tempering carbon steel, where a subsequent cleaning step is planned, a less complex and more cost-effective atmospheric furnace is often sufficient.

Ultimately, a retort furnace is chosen when precise control over the chemical environment is just as important as control over the temperature.

Summary Table:

| Application | Key Benefit |

|---|---|

| Bright Annealing | Prevents oxidation for clean, bright metal finishes |

| Sintering | Enables powder fusion in oxygen-free environments |

| Furnace Brazing | Ensures strong, flux-free bonds without surface oxides |

| Heat Treating Reactive Metals | Maintains purity of metals like titanium |

Need precise heat treatment solutions? KINTEK specializes in advanced high-temperature furnaces, including Retort Furnaces, designed for controlled atmosphere processes. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization to meet your unique experimental needs. Contact us today to enhance your lab's efficiency and achieve superior material outcomes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios