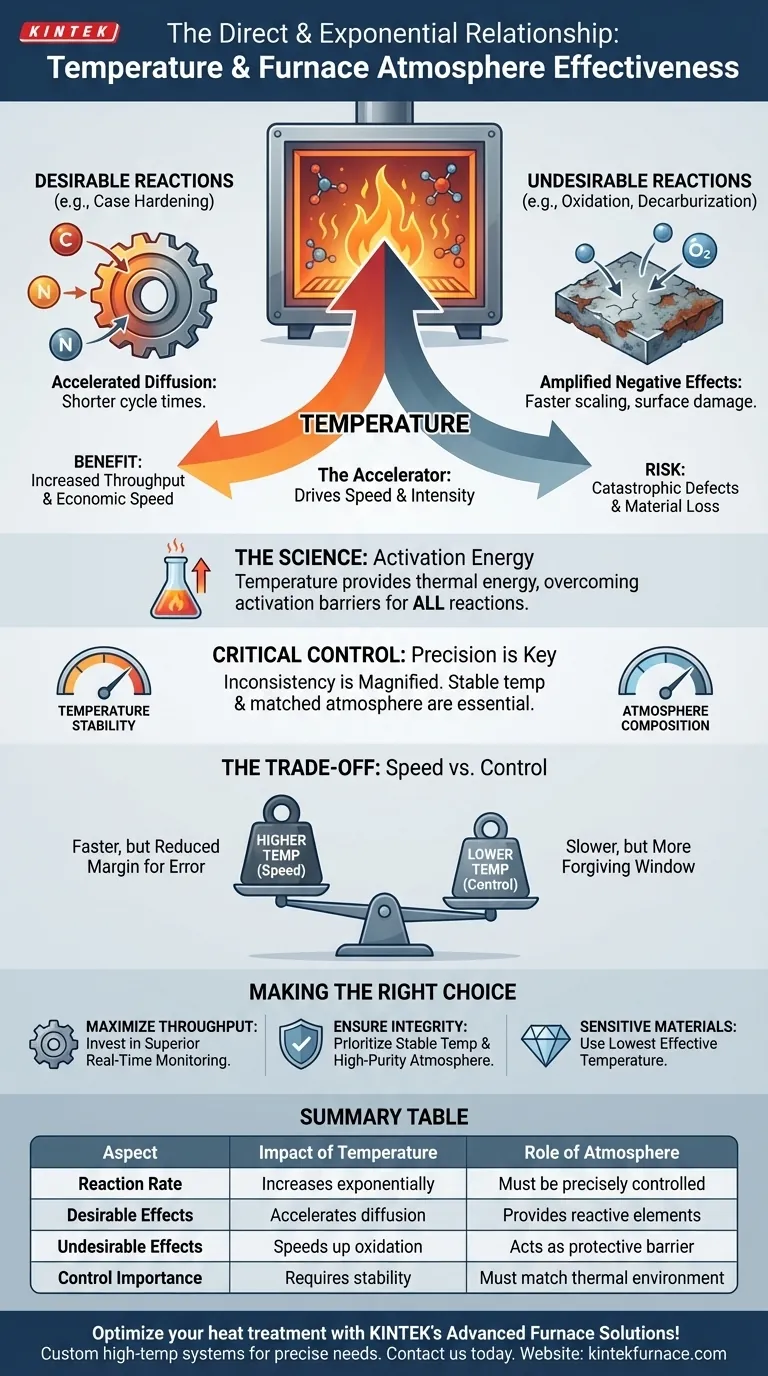

In any heat treatment process, the relationship between temperature and furnace atmosphere is one of direct and exponential influence. Temperature is the accelerator that determines the speed and intensity of all chemical reactions, both wanted and unwanted, between the atmosphere and the material's surface. A rise in temperature dramatically increases the reactivity of the system, making the composition and control of the atmosphere exponentially more critical.

The fundamental relationship is this: higher temperatures act as a catalyst, dramatically increasing the rate of all reactions. This makes precise control over both temperature and atmosphere composition essential for achieving desired material properties while preventing catastrophic defects.

Why Temperature is the Engine of Atmosphere Reactions

To control a heat treatment process, you must understand that temperature provides the energy that drives atmospheric reactions. Without the correct thermal energy, even the perfect atmosphere is ineffective.

The Science of Activation Energy

Every chemical reaction, from beneficial carburizing to detrimental oxidation, requires a minimum amount of energy to begin, known as activation energy. Temperature provides this thermal energy. As the temperature rises, more energy is available, allowing reactions to proceed much more quickly and efficiently.

Accelerating Desirable Reactions

Many heat treatment processes, such as case hardening, rely on the diffusion of elements from a reactive atmosphere (like carbon or nitrogen) into the steel. Higher temperatures accelerate this diffusion rate, allowing for shorter cycle times. This is the primary reason for processing at elevated temperatures.

Amplifying Undesirable Reactions

However, this same acceleration applies to negative reactions. The protective purpose of an atmosphere is often to prevent oxidation (scaling) or decarburization. As temperatures climb, these undesirable reactions also speed up, placing a much higher demand on the purity and stability of the furnace atmosphere to counteract them.

The Critical Role of Precision Control

Because temperature amplifies the effect of the atmosphere, any inconsistency in one variable will be magnified by the other. This makes precise, integrated control the cornerstone of successful heat treatment.

The Need for Stable Temperature

As noted in advanced furnace designs, a precise temperature control system is not just a feature; it is a necessity. Fluctuations in temperature create an unstable environment where reaction rates are unpredictable. This leads to inconsistent case depths, variable hardness, and a lack of process repeatability.

Matching Atmosphere to Temperature

The choice of atmosphere is entirely dependent on the process temperature and the material being treated. An atmosphere that is perfectly inert or protective at 800°C might become reactive or fail to prevent oxidation at 1100°C. The atmosphere's composition must be engineered specifically for the thermal environment it will operate in.

Understanding the Trade-offs: Speed vs. Control

The decision to increase process temperature is a calculated risk that balances the economic benefit of speed against the technical risk of losing material control.

The Lure of Higher Temperatures

The primary driver for using higher temperatures is economic: faster reaction and diffusion rates lead to shorter cycle times and increased furnace throughput. This can significantly reduce the cost per part.

The Risk of Losing Control

The trade-off is a dramatically reduced margin for error. At high temperatures, a small deviation in atmosphere composition—such as a minor air leak introducing oxygen—can cause rapid, irreversible damage to the material. The process becomes less forgiving.

The Pitfall of Mismatched Systems

A common failure mode is upgrading a furnace's heating capability without simultaneously upgrading its atmosphere control system. Pushing an older atmosphere generator or control panel to keep up with a higher temperature range is a recipe for inconsistent quality and scrap parts.

Making the Right Choice for Your Process

Optimizing your furnace operations requires treating temperature and atmosphere as a single, interconnected system. Your primary goal will dictate where you focus your efforts.

- If your primary focus is maximizing throughput: You must invest in superior, real-time atmosphere monitoring and control systems, as high temperatures leave no room for error.

- If your primary focus is ensuring material integrity: Prioritize a stable, tightly-controlled temperature profile and a high-purity atmosphere, even if it requires longer cycle times.

- If you are processing highly sensitive or expensive materials: Use the lowest effective temperature possible to minimize the risk of unwanted surface reactions and create a more forgiving process window.

Ultimately, mastering heat treatment means viewing the furnace not as a heater with a gas, but as a complex chemical reactor where temperature dictates the entire outcome.

Summary Table:

| Aspect | Impact of Temperature | Role of Atmosphere |

|---|---|---|

| Reaction Rate | Increases exponentially with temperature | Must be precisely controlled to manage reactions |

| Desirable Effects | Accelerates diffusion (e.g., case hardening) | Provides reactive elements (e.g., carbon, nitrogen) |

| Undesirable Effects | Speeds up oxidation and decarburization | Acts as a protective barrier against surface damage |

| Control Importance | Requires stable temperature for repeatability | Composition must match thermal environment |

Optimize your heat treatment processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise matching to your unique experimental needs, enhancing throughput and material integrity. Contact us today to discuss how our expertise can elevate your results and efficiency!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What does nitrogen do in a furnace? Create an Inert, Oxygen-Free Atmosphere for Superior Results