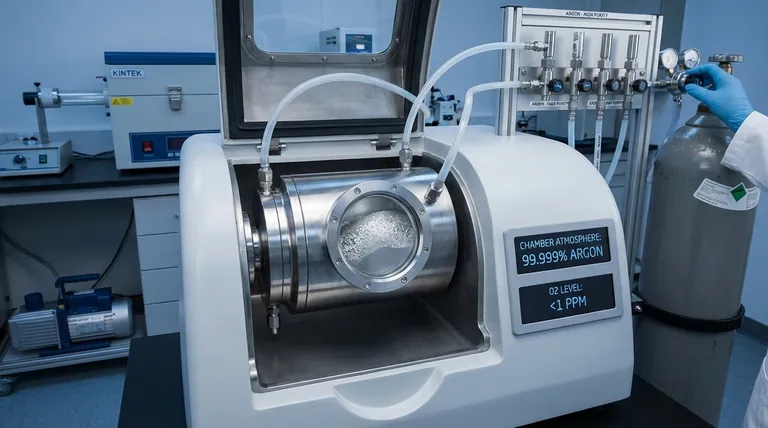

A high-purity argon atmosphere acts as a critical barrier against chemical contamination. During mechanical alloying, the combination of high-energy impacts and generated heat makes metal powders—particularly chemically active ones like molybdenum—highly susceptible to oxidation. The argon gas displaces oxygen and nitrogen, creating an inert environment that strictly preserves the chemical integrity of the material inside the milling jars.

Mechanical alloying drastically increases the surface area and temperature of powders, rendering them chemically hyper-active. Argon protection is mandatory to prevent these unstable surfaces from reacting with air, which would otherwise cause brittleness and degrade the final material's performance.

The Physics of Contamination

High Specific Surface Area

Mechanical alloying breaks bulk materials down into extremely fine powders. This process significantly increases the specific surface area of the material.

With more surface area exposed, the material becomes exponentially more sensitive to its environment. Without a protective barrier, there is simply too much surface area available for detrimental reactions with oxygen.

Reactivity of Fresh Surfaces

When a particle fractures during milling, it exposes "fresh" metal surfaces. These newly created surfaces are chemically unstable and highly reactive.

These fresh surfaces will instantly attempt to stabilize themselves by bonding with reactive elements in the air, such as oxygen or nitrogen. Argon prevents this by blanketing these fresh fractures in non-reactive atoms.

Heat-Induced Oxidation

The kinetic energy from the milling balls impacting the powder is largely converted into heat. This rise in temperature acts as a catalyst, accelerating chemical reactions.

Even materials that are relatively stable at room temperature may oxidize rapidly under the heat generated by high-energy impact. Argon ensures this thermal energy does not trigger unwanted chemical changes.

Consequences of Poor Atmosphere Control

Grain Boundary Embrittlement

One of the most severe consequences of insufficient argon protection is grain boundary embrittlement.

If oxides form, they often segregate to the boundaries between the metal grains. This weakens the cohesion of the material, making the final composite prone to cracking and structural failure.

Compromised Phase Purity

For the final product to perform as intended, the chemical composition must remain pure. This is particularly critical for complex alloys, such as Molybdenum or Co-9Al-9W systems.

Oxidation during the milling stage introduces impurities that persist through subsequent processing. This degrades the quality of sintering and alters the mechanical properties of the final component.

Understanding the Trade-offs

The Necessity of "High Purity"

It is not enough to simply use standard argon; the gas must be of high purity. Trace amounts of moisture or oxygen within lower-grade argon can still react with the highly active powder surfaces over long milling durations.

Sealing Integrity vs. Gas Quality

Even the purest gas is ineffective if the milling jar seal is compromised. Because mechanical alloying is often a prolonged process, even a microscopic leak can allow enough atmospheric air to enter and ruin the powder batch.

Making the Right Choice for Your Goal

To ensure the success of your mechanical alloying process, select your atmospheric controls based on your specific material objectives:

- If your primary focus is Structural Reliability: Prioritize argon quality to prevent oxide segregation, specifically avoiding grain boundary embrittlement that causes premature fracture.

- If your primary focus is Sintering Quality: Maintain a strict inert environment to ensure high phase purity, allowing for optimal densification during the heating stages.

By rigorously maintaining an inert argon atmosphere, you convert a chaotic, high-energy process into a controlled method for creating superior composite materials.

Summary Table:

| Factor | Impact on Milling | Role of Argon Protection |

|---|---|---|

| Surface Area | Drastic increase leads to hyper-reactive powder | Prevents oxygen/nitrogen from bonding with new surfaces |

| Heat Generation | Impact energy converts to heat, accelerating oxidation | Acts as an inert thermal barrier preventing chemical reactions |

| Phase Purity | Contaminants degrade sintering and mechanical traits | Maintains chemical integrity and precise alloy composition |

| Grain Boundaries | Oxides cause embrittlement and structural failure | Ensures strong cohesion and resistance to cracking |

Master Your Material Purity with KINTEK

Don't let oxidation compromise your research or production. Backed by expert R&D and manufacturing, KINTEK offers specialized milling jars and high-temperature systems including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique mechanical alloying needs. Whether you are working with Molybdenum or complex Co-9Al-9W systems, our technology ensures the strict atmospheric control required for superior composite performance.

Ready to elevate your lab's precision? Contact us today to find your custom solution!

References

- Haochen Guan, Zhangjian Zhou. The Effect of Cr Addition on the Strength and High Temperature Oxidation Resistance of Y2O3 Dispersion Strengthened Mo Composites. DOI: 10.3390/ma17112550

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- Why are retort furnaces significant in industrial applications? Unlock Precision Heat Treatment and Superior Material Quality

- Why use nitrogen atmosphere control in chromite reduction? Ensure Process Integrity and Prevent Oxidation

- What are the common types of inert atmosphere furnaces? Choose the Best for Your Materials

- What are the main application fields of atmosphere furnaces? Essential for Metal, Electronics, and R&D

- What is an atmosphere box furnace and what are its primary uses? Essential for Controlled Heat Processing

- How does a reactive furnace atmosphere benefit heat treatment? Enhance Surface Hardness and Wear Resistance

- Why is it necessary to use an atmosphere furnace with argon gas? Ensure Precise Alloy Austenitization & Protection

- Why is high-purity inert gas protection necessary in a laboratory furnace? Ensure Integrity for Sensitive Ceramics