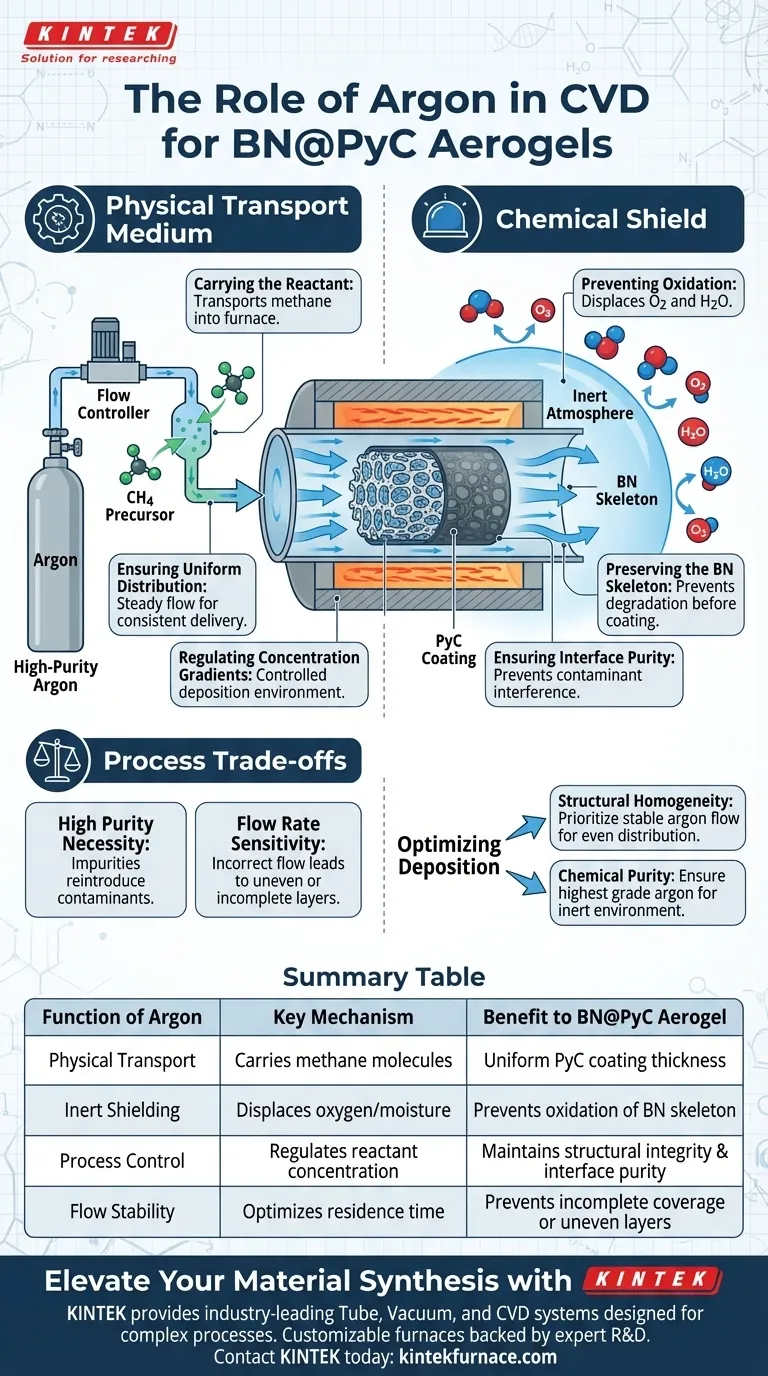

High-purity argon serves two fundamental functions during the Chemical Vapor Deposition (CVD) of BN@PyC aerogels: it acts as a physical transport medium and a chemical shield. Specifically, it carries methane molecules into the furnace to ensure they are distributed evenly, while simultaneously creating an inert atmosphere that prevents the oxidation of the boron nitride (BN) skeleton and the pyrolytic carbon (PyC) coating.

High-purity argon facilitates the precise, uniform delivery of carbon precursors while eliminating oxidative threats, ensuring the structural integrity and stable interface bonding of the final aerogel composite.

The Mechanism of Precursor Transport

Carrying the Reactant

In this CVD process, methane acts as the carbon precursor required to form the PyC coating. Argon serves as the carrier gas, physically transporting these methane molecules into the high-temperature tube furnace.

Ensuring Uniform Distribution

The flow of argon is not merely about movement; it is about consistency. By acting as a steady vehicle for the reactants, argon ensures that methane is delivered uniformly throughout the reaction zone.

Regulating Concentration Gradients

The stability of the argon flow directly influences the concentration gradient of the reactants. A stable flow allows for a controlled deposition environment, which is critical for achieving a uniform coating thickness on the BN nanobelts.

The Protective Role of the Inert Atmosphere

Preventing Oxidation

At the high temperatures required for CVD, materials become highly reactive and susceptible to degradation. Argon creates an inert protective atmosphere that displaces oxygen and water vapor from the system.

Preserving the BN Skeleton

The boron nitride (BN) skeleton serves as the structural foundation of the aerogel. The argon shield prevents this skeleton from oxidizing, which would otherwise compromise the mechanical properties of the aerogel before the coating is even applied.

Ensuring Interface Purity

For the composite to function correctly, the bond between the BN skeleton and the new PyC layer must be strong. Argon ensures chemical purity at this interface by preventing contaminants from interfering with the bonding process.

Understanding Process Trade-offs

The Necessity of High Purity

The benefits of argon are entirely dependent on its quality. You must use high-purity argon; any impurities in the gas stream can reintroduce the very oxygen or moisture you are trying to exclude.

Flow Rate Sensitivity

While argon aids uniformity, the flow rate must be calibrated precisely. An incorrect flow rate can alter the residence time of the methane, potentially leading to uneven PyC armor layers or incomplete coverage.

Optimizing Deposition for Your Goals

To achieve the best results in fabricating BN@PyC aerogels, you must balance the transport and protective functions of the carrier gas.

- If your primary focus is Structural Homogeneity: Prioritize the stability of the argon flow rate to ensure the methane precursor is distributed evenly across the entire aerogel structure.

- If your primary focus is Chemical Purity: Ensure the argon source is of the highest possible grade to strictly maintain an inert environment and prevent interface oxidation.

Mastering the use of argon is not just about moving gas; it is about creating the precise thermodynamic environment required for high-performance material synthesis.

Summary Table:

| Function of Argon | Key Mechanism | Benefit to BN@PyC Aerogel |

|---|---|---|

| Physical Transport | Carries methane molecules into the furnace | Ensures uniform PyC coating thickness |

| Inert Shielding | Displaces oxygen and moisture | Prevents oxidation of the BN skeleton |

| Process Control | Regulates reactant concentration | Maintains structural integrity & interface purity |

| Flow Stability | Optimizes residence time | Prevents incomplete coverage or uneven layers |

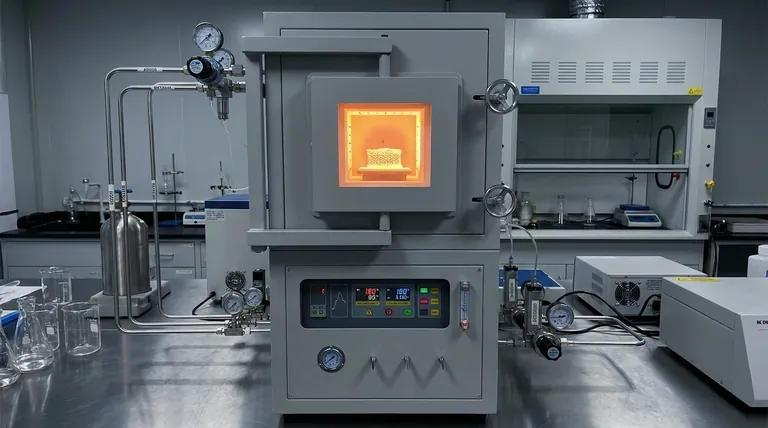

Elevate Your Material Synthesis with KINTEK

Precise gas control is only half the battle; high-performance results require the right thermal environment. KINTEK provides industry-leading Tube, Vacuum, and CVD systems designed to handle complex chemical vapor deposition processes with unmatched stability.

Whether you are synthesizing advanced BN@PyC aerogels or developing new composite materials, our customizable laboratory furnaces are backed by expert R&D to meet your unique specifications.

Ready to optimize your deposition process? Contact KINTEK today to discover how our high-temperature solutions can bring precision to your lab.

Visual Guide

References

- Meng Lan, Qiangang Fu. Armoring Boron Nitride with Pyrolytic Carbon Layers for Tunable Rigidity and Flexibility. DOI: 10.1002/advs.202504649

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is CVT preferred over solid-phase reaction for Janus RhSeCl? Key Advantages in Crystal Growth

- What are the main synthetic methods for 2D materials? Choose the Right Method for Your Application

- What is the function of methane as a reaction gas source in CVD for BN@PyC aerogels? Master Material Rigidity

- How do CVD coatings compare to spray-on PTFE coatings? Discover Superior Performance and Safety

- What are the two main types of CVD reactors? Choose the Right One for Your Application

- What are the different types of chemical vapour deposition? A Guide to Selecting the Right CVD Process

- Why must a CVD system use high-precision MFCs? Achieve Atomic Perfection in Your Material Synthesis

- How does chemical vapor infiltration work? A Guide to High-Performance Composite Manufacturing