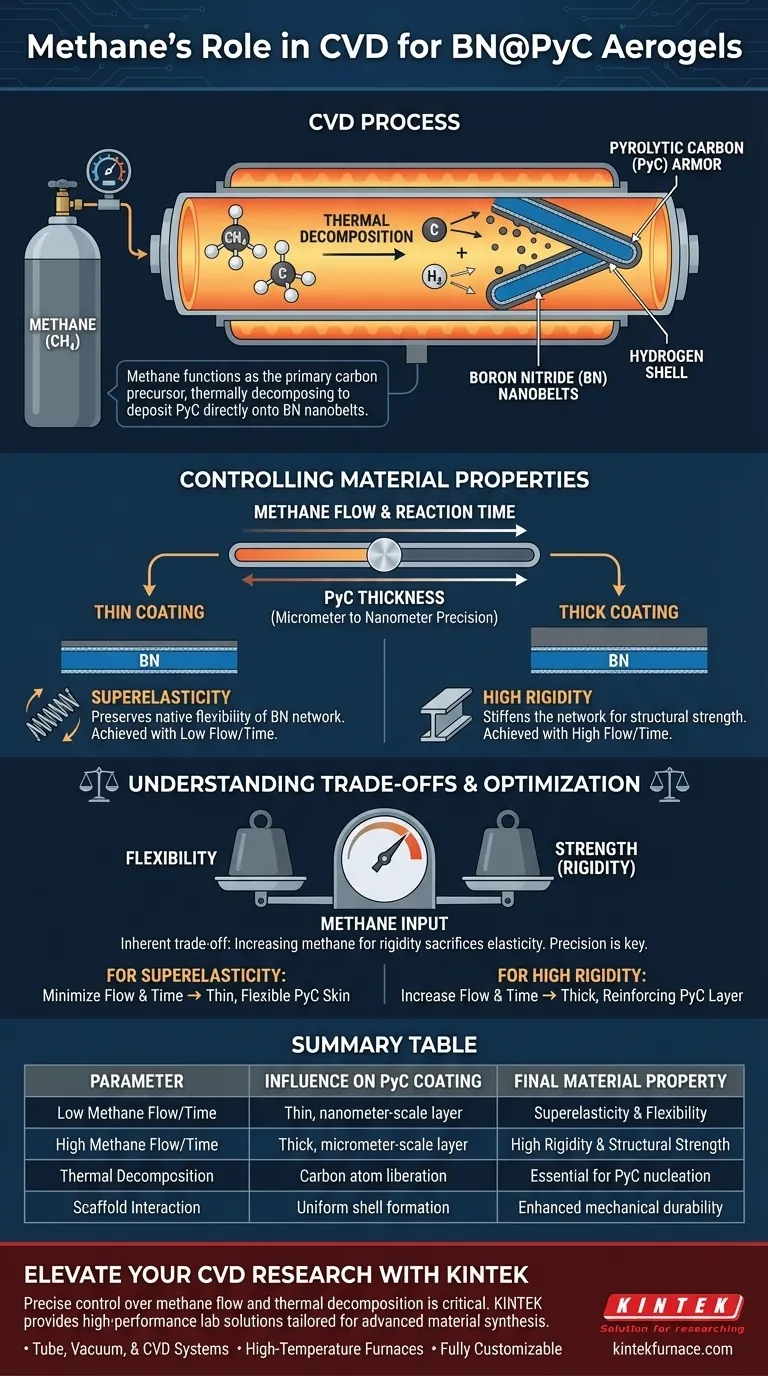

In the Chemical Vapor Deposition (CVD) process for BN@PyC aerogels, methane functions as the primary carbon precursor. It is introduced into a high-temperature tube furnace where it undergoes thermal decomposition, releasing carbon atoms that deposit as pyrolytic carbon (PyC) directly onto the surfaces of boron nitride (BN) nanobelts.

Methane acts as the tunable "armor" source for the aerogel structure. By regulating its flow and reaction time, you directly control the thickness of the carbon coating, allowing you to program the material’s mechanical properties from superelastic to highly rigid.

The Mechanism of Deposition

Thermal Decomposition

Inside the reaction chamber, the high thermal energy causes the methane gas to break down chemically. This decomposition is the critical first step, liberating carbon from the gaseous state so it is available for solid-state deposition.

Creating the PyC Armor

The released carbon does not float aimlessly; it nucleates and grows on the boron nitride (BN) scaffold. This forms a continuous shell of pyrolytic carbon (PyC) around the nanobelts, effectively jacketing the underlying ceramic structure.

Controlling Material Properties

Precision at the Nano-Scale

The interaction between the methane supply and the aerogel is highly controllable. By adjusting the methane flow rate and the reaction time, you can dictate the thickness of the deposited PyC layer with micrometer or nanometer precision.

Transitioning Mechanical States

This control over thickness is the key to determining the final physical behavior of the aerogel. The methane-derived coating drives a mechanical transition in the material.

A thinner coating preserves the native superelasticity of the BN network. A thicker coating, achieved through higher flow or longer exposure, stiffens the network, resulting in high rigidity.

Understanding the Trade-offs

The Sensitivity of Process Parameters

While methane allows for property tuning, the relationship between flow rate and final rigidity is sensitive. A lack of precision in controlling the gas source can lead to unintentional mechanical properties.

Balancing Flexibility and Strength

There is an inherent trade-off dictated by the methane input. Increasing the methane flow to maximize structural strength (rigidity) inherently sacrifices the aerogel's elasticity. You cannot maximize both properties simultaneously; the methane parameters forces a choice between flexibility and stiffness.

Optimizing the Coating Process

To achieve the specific mechanical performance required for your application, focus on manipulating the methane exposure variables.

- If your primary focus is Superelasticity: Minimize the methane flow rate and reaction time to create a nanometer-scale, flexible PyC skin.

- If your primary focus is High Rigidity: Increase the methane flow rate and extend the reaction time to build a thicker, micrometer-scale reinforcing layer.

The function of methane is ultimately to serve as the dial that sets the mechanical identity of your final aerogel product.

Summary Table:

| Parameter | Influence on PyC Coating | Final Material Property |

|---|---|---|

| Low Methane Flow/Time | Thin, nanometer-scale layer | Superelasticity & Flexibility |

| High Methane Flow/Time | Thick, micrometer-scale layer | High Rigidity & Structural Strength |

| Thermal Decomposition | Carbon atom liberation | Essential for PyC nucleation |

| Scaffold Interaction | Uniform shell formation | Enhanced mechanical durability |

Elevate Your CVD Research with KINTEK

Precise control over methane flow and thermal decomposition is critical for engineering the next generation of BN@PyC aerogels. KINTEK provides high-performance lab solutions tailored for advanced material synthesis. Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Tube, Vacuum, and CVD systems, as well as high-temperature furnaces—all fully customizable to meet your unique research requirements.

Ready to achieve nanometer-scale precision in your deposition process? Contact us today to find the perfect furnace solution for your lab!

Visual Guide

References

- Meng Lan, Qiangang Fu. Armoring Boron Nitride with Pyrolytic Carbon Layers for Tunable Rigidity and Flexibility. DOI: 10.1002/advs.202504649

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What future trends are expected in the development of CVD tube furnaces? Discover Smarter, More Versatile Systems

- What is the key difference between PVD and CVD? Choose the Best Coating Method for Your Needs

- What is the role of a vertical tube FCCVD system? Scalable High-Volume Synthesis of SWCNTs

- What is chemical vapor deposition in a CVD furnace? Build Materials with Atomic Precision

- Importance of Quartz Boat Positioning in CVD Growth of Beta-Cu2-xSe: Achieve Precise Phase Purity

- What are the benefits of CVD coating? Achieve Unmatched Conformality and Superior Adhesion

- What are the characteristics of the coating film produced by CVD? Achieve Superior Thin Films for Your Applications

- What are the advantages of chemical vapor deposition? Achieve Superior, Conformal Films for Complex 3D Structures