At its core, Chemical Vapor Deposition (CVD) is a sophisticated process for building solid materials from gas. Inside a specialized furnace, one or more volatile chemical gases, known as precursors, are introduced into a high-temperature chamber containing a substrate. The intense heat triggers chemical reactions that cause the precursors to decompose and deposit a thin, solid film onto the substrate's surface, constructing a new material layer by atomic layer.

CVD is not simply a coating technique; it is a highly controlled chemical synthesis process. By precisely manipulating gas, temperature, and pressure within a furnace, you can engineer a material's composition, thickness, and structure on a surface with exceptional accuracy.

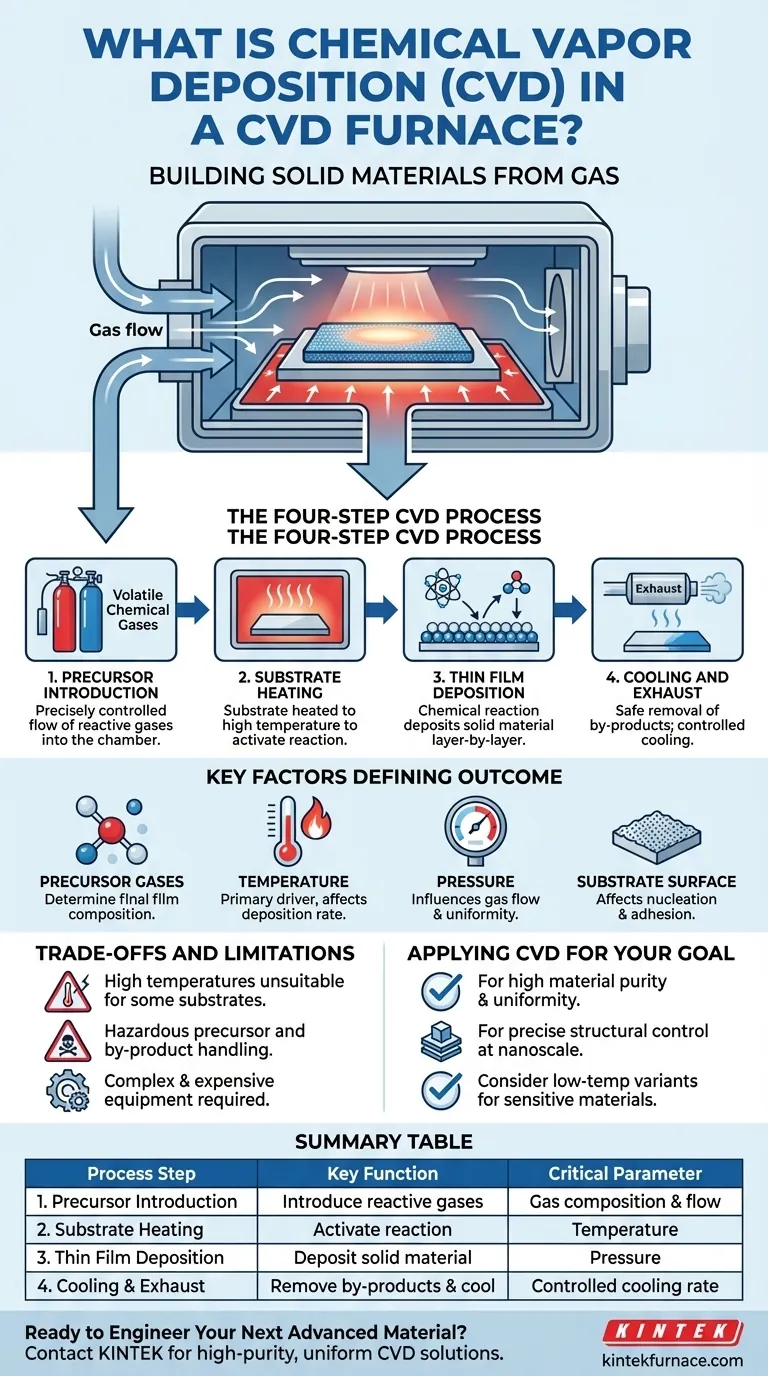

The Four-Step CVD Process Explained

The operation of a CVD furnace is a sequential process where each step is critical for the final quality of the film. Understanding this sequence provides a clear mental model of how a gas is transformed into a solid coating.

1. Precursor Introduction

The process begins by introducing specific precursor gases into the furnace's reaction chamber. The flow of these gases is precisely controlled to ensure the correct chemical mixture is available for the reaction.

2. Substrate Heating

Simultaneously, the furnace heats the substrate to a specific, high temperature. This temperature provides the necessary thermal energy to initiate the chemical reactions on or near the substrate surface.

3. Thin Film Deposition

As the hot precursor gases make contact with the heated substrate, they undergo a chemical reaction or decomposition. This reaction results in a solid material that deposits onto the substrate, forming a uniform and solid thin film.

4. Cooling and Exhaust

Once the desired film thickness is achieved, the process is stopped. Unreacted precursor gases and gaseous by-products from the reaction are safely removed from the chamber through a vacuum or exhaust system. The furnace and coated substrate are then cooled in a controlled manner.

Key Factors That Define the Outcome

The final properties of the deposited film are not accidental; they are a direct result of several tightly controlled process parameters. Mastering these variables is the key to achieving a desired result.

Precursor Gases

The specific chemical composition of the precursor gases directly determines the composition of the final film. Different precursors are used to create films of silicon, carbon, metal oxides, nitrides, and other materials.

Temperature

Temperature is the primary driver of the chemical reaction. It dictates the rate of deposition and influences the film's microstructure and crystalline quality.

Pressure

The pressure inside the chamber, which can range from a deep vacuum to atmospheric pressure, affects the flow of gas and the pathways of the chemical reactions. It is a critical factor in ensuring uniform coating, especially on complex shapes.

The Substrate Surface

The deposition process is sensitive to the condition of the substrate. Its surface roughness and chemical composition can influence how the film nucleates and grows, affecting the final adhesion and structure.

Understanding the Trade-offs and Limitations

While powerful, the CVD process has inherent complexities and constraints that must be considered for any practical application.

The Need for High Temperatures

Traditional thermal CVD requires very high temperatures to activate the chemical reactions. This makes it unsuitable for substrates that cannot withstand extreme heat, such as many plastics or pre-processed semiconductor wafers.

Precursor and By-product Handling

The precursor gases used in CVD can be toxic, flammable, or corrosive, requiring sophisticated safety and handling protocols. Likewise, the chemical by-products exhausted from the chamber may be hazardous and require treatment before release.

Process and Equipment Complexity

Achieving the high purity and uniformity that CVD is known for requires a complex system with precise control over gas flow, temperature, and pressure. This translates to expensive equipment and a high degree of operational expertise.

Applying CVD for Your Specific Goal

The decision to use CVD hinges on whether its unique capabilities align with your primary objective.

- If your primary focus is material purity and uniformity: CVD is an exceptional choice for creating high-quality, dense films with minimal defects, even across complex and intricate surfaces.

- If your primary focus is precise structural control: The layer-by-layer nature of CVD allows for engineering films with specific microstructures and thicknesses down to the nanometer scale.

- If you are working with temperature-sensitive substrates: You must carefully consider the high temperatures required for thermal CVD and explore lower-temperature variants or alternative deposition methods.

By understanding the interplay between these fundamental principles, you can effectively leverage CVD to build materials with precisely engineered properties.

Summary Table:

| CVD Process Step | Key Function | Critical Parameter |

|---|---|---|

| 1. Precursor Introduction | Introduce reactive gases into the chamber | Precursor gas composition & flow rate |

| 2. Substrate Heating | Activate the chemical reaction | Temperature (primary driver) |

| 3. Thin Film Deposition | Deposit solid material layer-by-layer | Pressure (for uniformity) |

| 4. Cooling & Exhaust | Safely remove by-products and cool the system | Controlled cooling rate |

Ready to Engineer Your Next Advanced Material with Precision?

KINTEK's advanced CVD furnace solutions are engineered for researchers and manufacturers who demand the highest levels of purity, uniformity, and structural control. Our deep customization capabilities ensure your specific process requirements—from unique precursor handling to complex temperature profiles—are met precisely.

Let's build your material future, atom by atom. Contact our experts today to discuss your project!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What are the main components of a PECVD system? Unlock Low-Temperature Thin Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection