The Chemical Vapor Transport (CVT) method is preferred for synthesizing Janus RhSeCl single crystals because it effectively manages the extreme kinetic differences between the high melting point of metal Rhodium (Rh) and the low sublimation point of non-metal Selenium (Se). Unlike solid-phase reactions, CVT utilizes a gaseous transport agent to bypass these disparities, preventing compositional inconsistencies and enabling the growth of high-quality, large-scale Janus single crystals.

The critical advantage of CVT lies in its ability to facilitate gas-phase growth through a controlled temperature gradient. By converting solid precursors into a vapor, this method overcomes the physical limitations of disparate melting points, ensuring the formation of uniform, high-purity single crystals.

Overcoming Thermodynamic Barriers

The primary challenge in synthesizing RhSeCl is the fundamental mismatch in the thermal properties of its constituent elements.

The Melting Point Disparity

The synthesis requires combining metal Rhodium (Rh) and non-metal Selenium (Se). Rh has a very high melting point, while Se has a comparatively low sublimation point.

In a traditional solid-phase reaction, heating the mixture enough to react the Rh often causes the Se to volatilize uncontrollably. This results in an inability to maintain the correct stoichiometry.

Preventing Compositional Inhomogeneity

Because of these kinetic differences, solid-phase reactions frequently suffer from uneven mixing.

The reactants do not diffuse uniformly, leading to compositional inhomogeneities. This results in low-quality crystals that lack the precise structural integrity required for Janus materials.

The Mechanics of Gas-Phase Growth

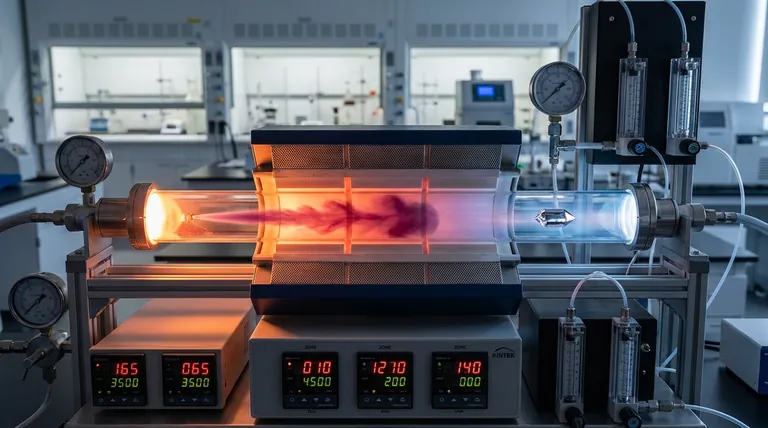

CVT solves the issues inherent to solid-state reactions by shifting the growth medium from solid to gas.

Utilizing a Transport Agent

Instead of relying on direct contact between solids, CVT employs a gaseous transport agent (such as iodine) within a vacuum-sealed quartz tube.

This agent reacts with the solid precursors to convert them into a gaseous phase. This bypasses the need to melt the Rhodium directly in contact with the Selenium solid.

The Role of Temperature Gradients

The process is driven by a precise temperature gradient.

The gaseous material migrates from the hotter source zone to a cooler growth zone. This controlled migration ensures that the material is deposited gradually and consistently.

Achieving High-Quality Structure

This method enables the growth of large-scale single crystals.

By controlling the vapor transport, the method ensures the resulting crystals are homogeneous. This is essential for producing the specific Janus structure and ensuring high material quality.

Understanding the Trade-offs

While CVT is superior for quality, it introduces complexities that must be managed.

Operational Complexity

CVT is significantly more complex than solid-phase reactions.

It requires the preparation of vacuum-sealed quartz tubes and precise control over multi-zone furnaces to maintain the necessary temperature gradients.

Time Intensity

The process relies on the migration and recrystallization of vapor.

This growth mechanism is inherently slower than direct solid-state sintering. Producing millimeter-sized crystals suitable for anisotropic study requires time and patience.

Making the Right Choice for Your Goal

To determine if CVT is the correct approach for your specific application, consider the following:

- If your primary focus is crystal purity and size: You must use CVT to navigate the kinetic mismatch between Rh and Se, ensuring a homogeneous single crystal.

- If your primary focus is rapid synthesis of polycrystalline powder: You might attempt solid-phase reactions, but you must accept a high risk of impurities and stoichiometric imbalance.

For complex materials like Janus RhSeCl, the precision of gas-phase transport is the only reliable path to structural integrity.

Summary Table:

| Feature | Solid-Phase Reaction | Chemical Vapor Transport (CVT) |

|---|---|---|

| Phase State | Direct solid-to-solid contact | Gas-phase mediated transport |

| Thermal Management | Struggles with disparate melting points | Bypasses melting points via vapor |

| Purity & Quality | Risk of impurities and inhomogeneities | High purity, large-scale single crystals |

| Mechanism | Diffusion-limited | Controlled temperature gradient |

| Complexity | Relatively simple | High (vacuum seals & multi-zone furnace) |

Optimize Your Advanced Material Synthesis with KINTEK

Achieve unmatched precision in your single crystal growth today. Backed by expert R&D and manufacturing, KINTEK offers specialized Tube, Vacuum, and CVD systems, alongside other laboratory high-temp furnaces—all fully customizable to manage the complex temperature gradients required for Chemical Vapor Transport.

Whether you are synthesizing Janus RhSeCl or other advanced materials, our equipment ensures the thermal stability and vacuum integrity your research demands.

Ready to elevate your lab's performance? Contact us today to discuss your unique synthesis needs!

References

- Kefeng Liu, Huiyang Gou. Optimized Synthesis and Characterization of Janus RhSeCl with Uniform Anionic Valences, Nonlinear Optical and Optoelectronic Properties. DOI: 10.1002/advs.202505279

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- How does a Molecular Turbo Pump contribute to ZTO thin film quality? Master High-Vacuum Deposition Precision

- What are the advantages of using a high-purity quartz tube in CVD? Unlock Superior Film Growth and Purity

- What are the techniques for vapor deposition? PVD vs. CVD for Superior Thin-Film Coatings

- What role do CVD furnaces play in the semiconductor industry? Essential for Precise Thin-Film Deposition in Chip Fabrication

- How does chemical vapor infiltration work? A Guide to High-Performance Composite Manufacturing

- What are the key considerations for selecting a CVD furnace for industrial applications? Optimize for Cost and Performance

- Why is an RTP furnace used for selenium thin films? Master Precision Recovery with Rapid Thermal Processing

- Why is a mixture of Argon and Hydrogen used for 2D In2Se3? Optimize Growth and Prevent Oxidation