Selecting an industrial CVD furnace is a critical decision that balances core technical capabilities with the practical demands of large-scale manufacturing. The key is to match the furnace's specifications—such as its temperature range, atmosphere control, and gas flow precision—with your specific industrial requirements for throughput, process consistency, and long-term cost of ownership.

The most effective approach is not to purchase the furnace with the highest specifications, but to select the one whose capabilities are precisely aligned with your specific material, required production volume, and operational budget. A mismatch in any of these areas leads to inefficiency and unnecessary cost.

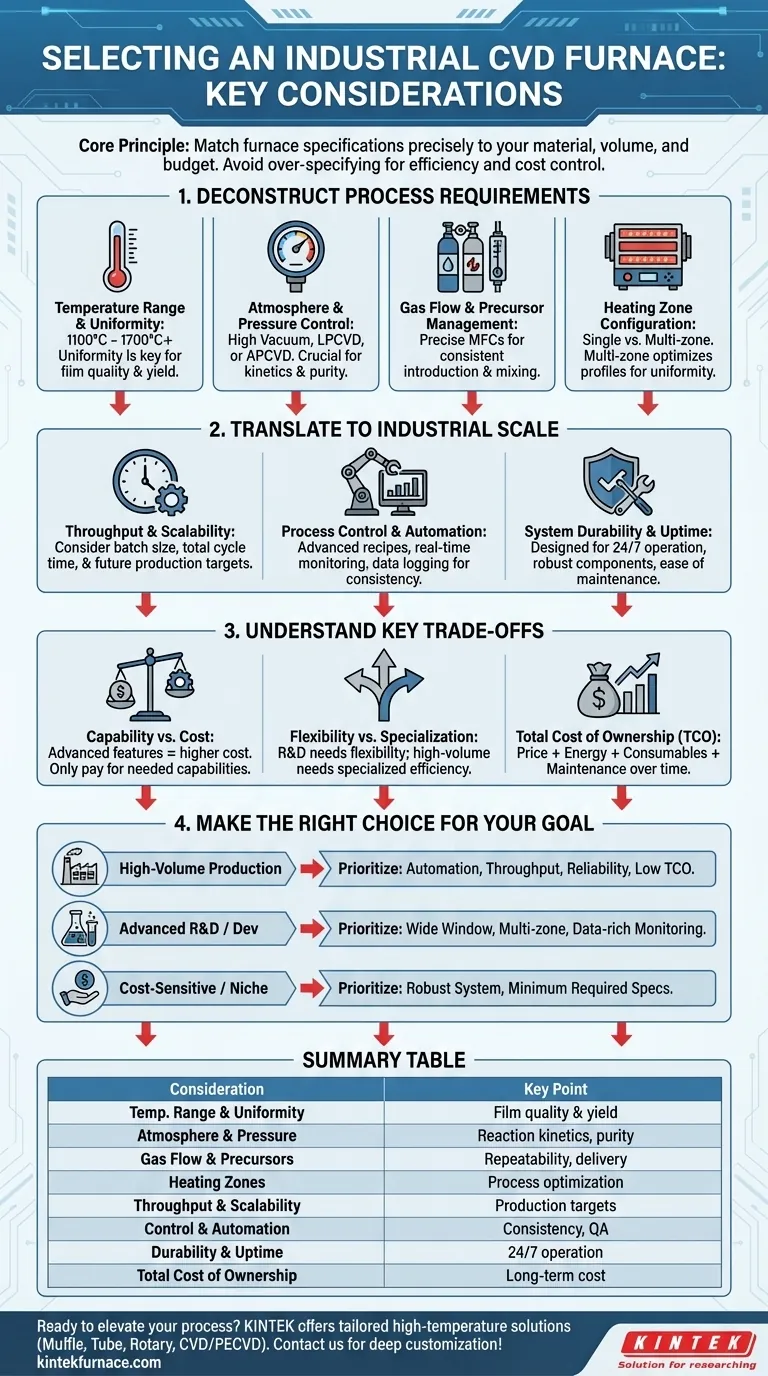

Deconstructing Your Process Requirements

Before evaluating any hardware, you must have a complete understanding of your chemical vapor deposition (CVD) process. The furnace is the environment where this process lives; its parameters define your success.

Temperature Range and Uniformity

Your choice of materials and desired film properties dictate the required operating temperature. Furnaces are often grouped by their maximum temperature, with common ranges falling between 1100°C, 1400°C, and 1700°C or higher.

Just as important is temperature uniformity across the entire heating zone. Poor uniformity leads to variations in film thickness and quality, directly impacting product yield and performance.

Atmosphere and Pressure Control

The furnace must reliably create and maintain the specific atmosphere your process needs. This can range from a high vacuum to low-pressure (LPCVD) or atmospheric pressure (APCVD) environments.

Precise pressure control is essential for managing reaction kinetics and ensuring the deposited film has the desired morphology and purity.

Gas Flow and Precursor Management

A CVD furnace is useless without a precise gas delivery system. This involves mass flow controllers (MFCs) that regulate the flow of precursor gases, carrier gases, and reactants with high accuracy.

The system's ability to introduce, mix, and purge these gases consistently recipe after recipe is fundamental to achieving repeatable results.

Heating Zone Configuration

Furnaces can have a single heating zone or multiple zones. A single zone is simpler and often sufficient for smaller or less sensitive processes.

Multi-zone furnaces offer superior control over the temperature profile along the length of the process tube. This is critical for optimizing deposition uniformity on large substrates or for running complex, temperature-sensitive reactions.

Translating Process Needs to Industrial Scale

A furnace that works in a lab may not be suitable for a factory floor. Industrial applications introduce a new set of demands focused on economics and reliability.

Throughput and Scalability

This is a primary industrial driver. You must evaluate the furnace's capacity, such as the number of wafers or substrates it can process in a single batch.

Consider the entire cycle time, including loading, pump-down, heating, deposition, cooling, and unloading. The design must be scalable to meet future production targets.

Process Control and Automation

To ensure consistency across thousands of runs, advanced automation is non-negotiable. Modern industrial furnaces use computer control to execute complex recipes without operator intervention.

Look for features like automated data logging, real-time process monitoring, and closed-loop feedback controls. This ensures every run is identical and provides a complete history for quality assurance.

System Durability and Uptime

An industrial furnace is a workhorse that must run 24/7 with minimal interruption. Its construction must be robust, using high-quality components designed for longevity in a demanding environment.

Factor in the ease of maintenance and the availability of support and spare parts. Excessive downtime for repairs or scheduled maintenance directly erodes profitability.

Understanding Key Trade-offs and Pitfalls

Choosing a furnace involves balancing competing priorities. Being aware of these trade-offs prevents costly mistakes.

Capability vs. Cost

The most advanced, high-temperature, multi-zone furnace is also the most expensive. Over-specifying your furnace means paying for capabilities you will never use. A rigorous analysis of your actual process needs is the best defense against this.

Flexibility vs. Specialization

A furnace designed for maximum flexibility (e.g., a wide variety of processes and materials) is ideal for R&D but is often less efficient for high-volume manufacturing.

Conversely, a highly specialized furnace optimized for one process will deliver the highest throughput and lowest cost per part, but it cannot be easily repurposed if your product mix changes.

Ignoring the Total Cost of Ownership (TCO)

The initial purchase price is only one part of the equation. You must calculate the TCO, which includes installation, energy consumption, process gases, consumables, and scheduled maintenance. A cheaper furnace with high energy costs or frequent downtime can be far more expensive in the long run.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary strategic objective.

- If your primary focus is high-volume, stable production: Prioritize automation, throughput, reliability, and a low cost of ownership over flexibility.

- If your primary focus is advanced R&D or process development: Prioritize a wide operating window, multi-zone control, and data-rich monitoring to explore new materials and processes.

- If your primary focus is a cost-sensitive or niche application: Concentrate on a robust system that meets your minimum required specifications without over-investing in non-essential features.

A systematic evaluation of these factors will ensure you invest not just in a piece of equipment, but in a capability that drives your organization's success.

Summary Table:

| Consideration | Key Points |

|---|---|

| Temperature Range & Uniformity | Dictated by materials; affects film quality and yield. |

| Atmosphere & Pressure Control | Essential for reaction kinetics and film purity. |

| Gas Flow & Precursor Management | Ensures repeatability with precise gas delivery. |

| Heating Zone Configuration | Single or multi-zone for process optimization. |

| Throughput & Scalability | Batch capacity and cycle time for production targets. |

| Process Control & Automation | Enables consistency and quality assurance. |

| Durability & Uptime | Robust design for minimal downtime and maintenance. |

| Total Cost of Ownership | Includes energy, gases, and maintenance costs. |

Ready to elevate your industrial processes with a tailored CVD furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production requirements, boosting efficiency and reducing costs. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

People Also Ask

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What temperature ranges can a CVD Tube Furnace achieve with different tube materials? Unlock High-Temp Precision for Your Lab

- Where is a CVD Tube Furnace commonly used? Essential for High-Tech Materials and Electronics

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision

- What is the working principle of a CVD tube furnace? Achieve Precise Thin Film Deposition for Your Lab