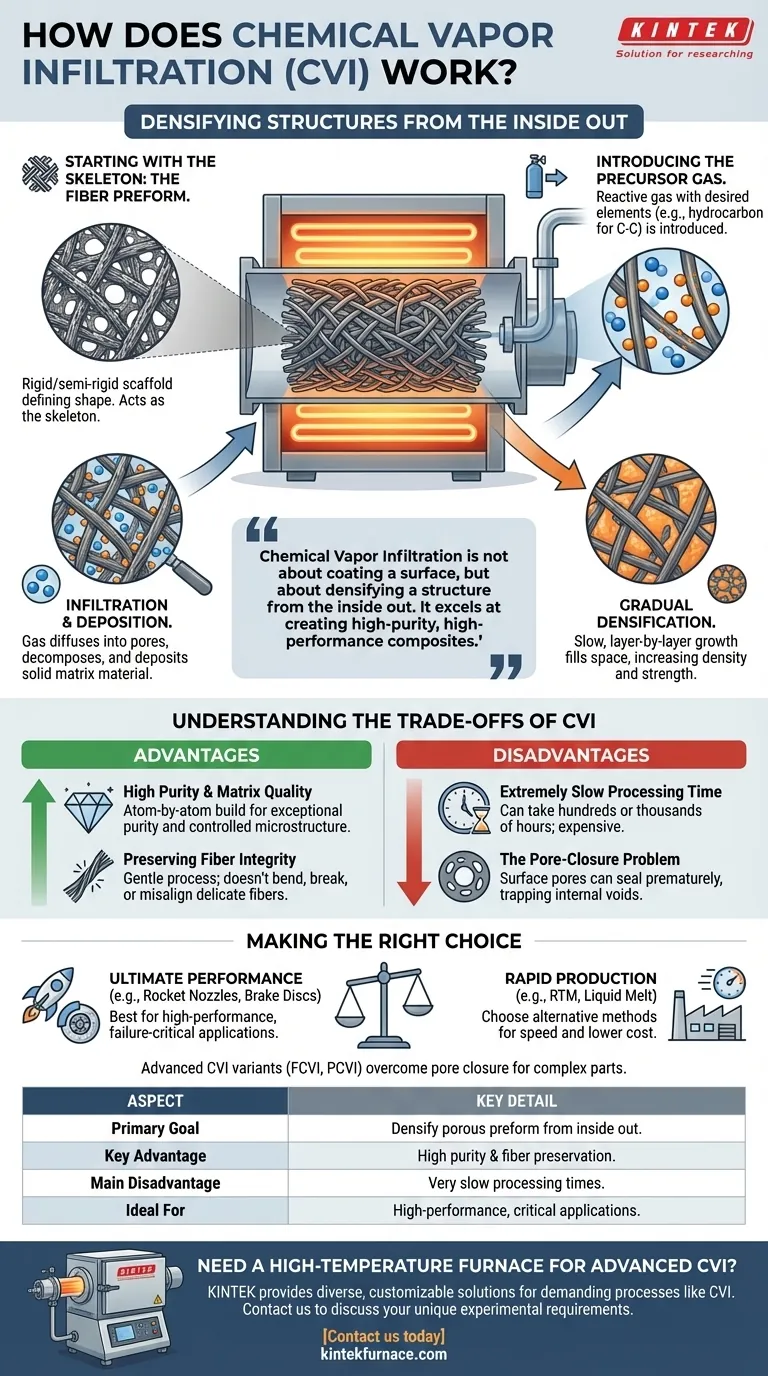

At its core, Chemical Vapor Infiltration (CVI) is a manufacturing process used to build a dense solid material inside a porous fibrous structure. It works by placing a fiber "preform"—like a scaffold of carbon or ceramic fibers—into a high-temperature furnace and introducing a reactive gas. This gas penetrates the pores of the preform and decomposes, depositing a solid matrix material directly onto the fibers and gradually filling the empty space.

Chemical Vapor Infiltration is not about coating a surface, but about densifying a structure from the inside out. It excels at creating high-purity, high-performance composites without damaging the fiber skeleton, but this precision comes at the significant cost of very long processing times.

The Goal of CVI: Building a Composite from the Inside Out

The fundamental purpose of CVI is to transform a lightweight, porous fiber preform into a solid, dense, and incredibly robust composite material. This is achieved through a meticulous, multi-step process.

Starting with the Skeleton: The Fiber Preform

The process begins with a preform, which is a rigid or semi-rigid structure made of woven or non-woven fibers. This preform acts as the skeleton for the final component, defining its shape and providing its primary directional strength. Common materials include carbon, silicon carbide (SiC), or alumina fibers.

Introducing the Precursor Gas

The fiber preform is placed inside a reactor furnace. A carefully chosen precursor gas is then introduced. This gas contains the chemical elements needed to form the desired solid matrix. For example, to create a carbon matrix in a carbon-fiber preform (for a Carbon-Carbon composite), a hydrocarbon gas like methane or propane is used.

The Infiltration and Deposition Step

This is the critical stage. The precursor gas molecules diffuse into the network of pores throughout the preform. The high temperature inside the furnace triggers a chemical reaction, causing the gas to decompose. The solid component of the gas—for instance, carbon atoms from the methane—deposits directly onto the surface of the individual fibers.

Gradual Densification

This deposition is not instantaneous. It is a slow, layer-by-layer growth process. As the matrix material builds up on the fibers, the pores within the preform become progressively smaller. The fibers become bonded together by the newly formed matrix, increasing the density and strength of the entire component.

Understanding the Trade-offs of CVI

Like any advanced manufacturing process, CVI involves a specific set of advantages and disadvantages that make it suitable for some applications but impractical for others.

Advantage: High Purity and Matrix Quality

Because the matrix is built atom by atom from a gaseous phase, the resulting material is exceptionally pure and has a highly controlled microstructure. This leads to superior thermal and mechanical properties compared to matrix materials formed from liquid-based methods.

Advantage: Preserving Fiber Integrity

CVI is a gentle, low-stress process. Unlike methods that involve forcing molten metal or viscous resin into a preform under high pressure, CVI does not bend, break, or misalign the delicate fibers. This preserves the intended structural integrity of the fiber skeleton.

Disadvantage: Extremely Slow Processing Time

The primary drawback of CVI is its speed. The process relies on slow gas diffusion into tiny pores and gradual deposition. Fully densifying a part can take hundreds or even thousands of hours, making it expensive and unsuitable for high-volume production.

Disadvantage: The Pore-Closure Problem

In the simplest form of CVI, deposition can occur faster on the outer surfaces of the preform. This can cause the surface pores to seal shut prematurely, trapping voids deep inside the component and creating a weak, incompletely densified part. Advanced techniques like thermal-gradient CVI were developed specifically to combat this issue by forcing deposition to occur from the inside out.

Making the Right Choice for Your Goal

Selecting CVI depends entirely on balancing the need for ultimate performance against the constraints of time and cost.

- If your primary focus is ultimate material performance and purity: CVI is the superior choice for creating components like carbon-carbon brake discs, rocket nozzles, or turbine engine parts where failure is not an option.

- If your primary focus is rapid production and lower cost: You should explore alternative methods like Resin Transfer Molding (RTM) or liquid melt infiltration, which are significantly faster but yield different material properties.

- If you are dealing with a complex, thick-walled component: Consider advanced CVI variants like thermal-gradient (FCVI) or pressure-pulsed (PCVI) to overcome pore closure and accelerate densification.

Understanding these core principles allows you to select the right densification strategy for your specific material and performance requirements.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Goal | Densify a porous fiber preform from the inside out. |

| Key Advantage | High-purity matrix & preservation of delicate fiber integrity. |

| Main Disadvantage | Extremely slow processing times (hundreds to thousands of hours). |

| Ideal For | High-performance applications like rocket nozzles & brake discs where failure is not an option. |

Need a High-Temperature Furnace for Advanced CVI Processes?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions precisely engineered for demanding processes like Chemical Vapor Infiltration. Our product line, including Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements and overcome challenges like pore-closure.

Contact us today to discuss how our furnace solutions can help you achieve superior composite performance.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation