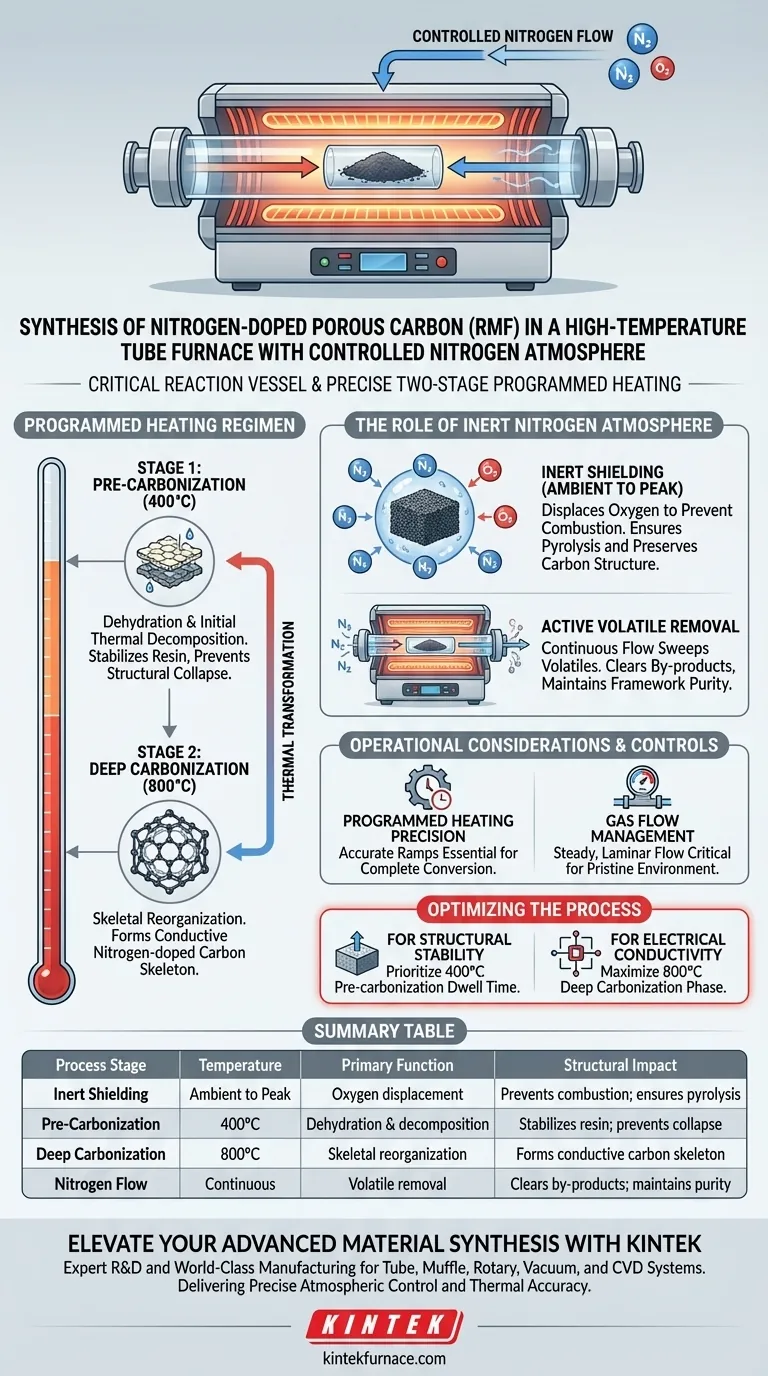

The high-temperature tube furnace serves as the critical reaction vessel for synthesizing Nitrogen-doped Porous Carbon (RMF). It facilitates a precise, two-stage programmed heating regimen under a protective nitrogen shield to convert organic precursors into a stable carbon framework. By maintaining an strictly oxygen-free environment, the system prevents combustion while driving the thermal decomposition and skeletal reorganization necessary for high conductivity.

The controlled nitrogen atmosphere enables deep carbonization by efficiently removing volatile by-products and preventing oxidation, transforming the precursor resin into a robust nitrogen-doped carbon skeleton through a strictly managed thermal cycle.

The Mechanics of Thermal Transformation

The Role of the Inert Atmosphere

The primary function of the nitrogen atmosphere is to create an inert environment. At the high temperatures required for this process, the presence of oxygen would cause the organic resin to burn rather than carbonize.

By displacing oxygen, nitrogen allows the material to undergo pyrolysis. This ensures the chemical changes are strictly thermal, preserving the carbon structure rather than converting it to ash or carbon dioxide.

Stage 1: Pre-Carbonization at 400°C

The first phase of the programmed heating process raises the RMF precursor to 400°C. This stage is critical for preparing the material structure for final hardening.

During this phase, the material undergoes dehydration and initial thermal decomposition. This step stabilizes the organic resin, preventing structural collapse before the higher temperatures are reached.

Stage 2: Deep Carbonization at 800°C

Following pre-carbonization, the temperature is elevated to 800°C for deep carbonization. This high-energy state triggers the fundamental skeletal reorganization of the material.

It is during this phase that the material's final properties are locked in. The process converts the pre-carbonized resin into a highly conductive Nitrogen-doped carbon skeleton, granting the RMF its functional electronic characteristics.

Active Removal of Volatiles

As the organic resin decomposes, it releases gaseous by-products. The continuous flow of nitrogen acts as a sweeping mechanism.

This flow physically carries these volatile by-products out of the furnace tube. Removing these gases is essential to prevent them from re-depositing on the material or interfering with the purity of the carbonization process.

Operational Considerations and Controls

Importance of Programmed Heating

The success of this synthesis relies heavily on the accuracy of the temperature ramp. The distinction between the 400°C and 800°C stages is not arbitrary; skipping the pre-carbonization step can lead to structural defects or incomplete conversion.

Gas Flow Management

While the nitrogen atmosphere prevents oxidation, the rate of flow is equally important. Inadequate flow may fail to clear volatile by-products efficiently, potentially contaminating the porous structure.

Conversely, turbulent flow could disrupt the thermal stability around the sample. The goal is a steady, laminar flow that ensures a pristine environment for skeletal reorganization.

Optimizing the Synthesis Process

To ensure the highest quality Nitrogen-doped Porous Carbon (RMF), align your process controls with your specific material goals.

- If your primary focus is Structural Stability: Prioritize the precision of the 400°C pre-carbonization dwell time to ensure complete dehydration before increasing thermal stress.

- If your primary focus is Electrical Conductivity: Ensure the 800°C deep carbonization phase is maintained sufficiently long to maximize skeletal reorganization and graphitization.

Mastering the balance between thermal staging and inert gas flow is the key to unlocking the full potential of RMF materials.

Summary Table:

| Process Stage | Temperature | Primary Function | Structural Impact |

|---|---|---|---|

| Inert Shielding | Ambient to Peak | Oxygen displacement | Prevents combustion; ensures pyrolysis |

| Pre-Carbonization | 400°C | Dehydration & decomposition | Stabilizes resin; prevents structural collapse |

| Deep Carbonization | 800°C | Skeletal reorganization | Forms conductive nitrogen-doped carbon skeleton |

| Nitrogen Flow | Continuous | Volatile removal | Clears by-products; maintains framework purity |

Elevate Your Advanced Material Synthesis with KINTEK

Precise atmospheric control and thermal accuracy are the cornerstones of high-performance Nitrogen-doped Porous Carbon (RMF) production. At KINTEK, we understand that your research depends on the reliability of your thermal environment.

Backed by expert R&D and world-class manufacturing, we provide high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to meet the most rigorous scientific standards. Whether you require a standard high-temperature tube furnace or a fully customizable system for unique carbonization needs, our equipment delivers the laminar gas flow and programmed heating precision necessary for superior conductivity and structural stability.

Ready to optimize your lab's high-temperature processes?

Contact KINTEK today to discuss your custom furnace requirements.

Visual Guide

References

- Qi Chen, Licheng Ling. Enhanced Electrochemical Performance of Dual-Ion Batteries with T-Nb2O5/Nitrogen-Doped Three-Dimensional Porous Carbon Composites. DOI: 10.3390/molecules30020227

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does a tube vacuum furnace ensure quality during the solution treatment of aluminum matrix composites? Unlock Precision and Purity for Superior Materials

- What is the function of a high-temperature tube furnace in the synthesis of SPC-Fe? Master Graphitic Carbon Production

- Can a quartz tube furnace be used for melting materials? Unlock Precise Melting with Visual Control

- How does the direct annealing process in a tube furnace affect iridium-based inverse opals? Expert Insights

- What physical conditions does a dual-zone tube furnace provide for CVT? Master Precision Thermal Gradient Control

- What is the function of a Tube Furnace in the preparation of WSe2 thin films? Master Precise Atomic Deposition

- What are the key features of an atmosphere tube furnace? Unlock Precise Heat and Gas Control

- What is the core function of a laboratory tube furnace in torrefaction? Optimize Fruit and Vegetable Waste Conversion