The high-temperature electric furnace serves as the foundational stability mechanism for melting radiation shielding glass. It creates and maintains a precise 1000°C environment, which is critical for initiating the thermal decomposition of oxide powders and driving the physicochemical reactions necessary to achieve a uniform molten state. By strictly regulating temperature, the furnace controls the melt's viscosity and fluidity, directly dictating the quality of the final casting.

Core Takeaway The furnace is not merely a heating element; it is a control system for material consistency. Its primary function is to stabilize the melting environment at 1000°C, ensuring that viscosity and fluidity remain within the narrow window required for high-quality molding and effective radiation protection.

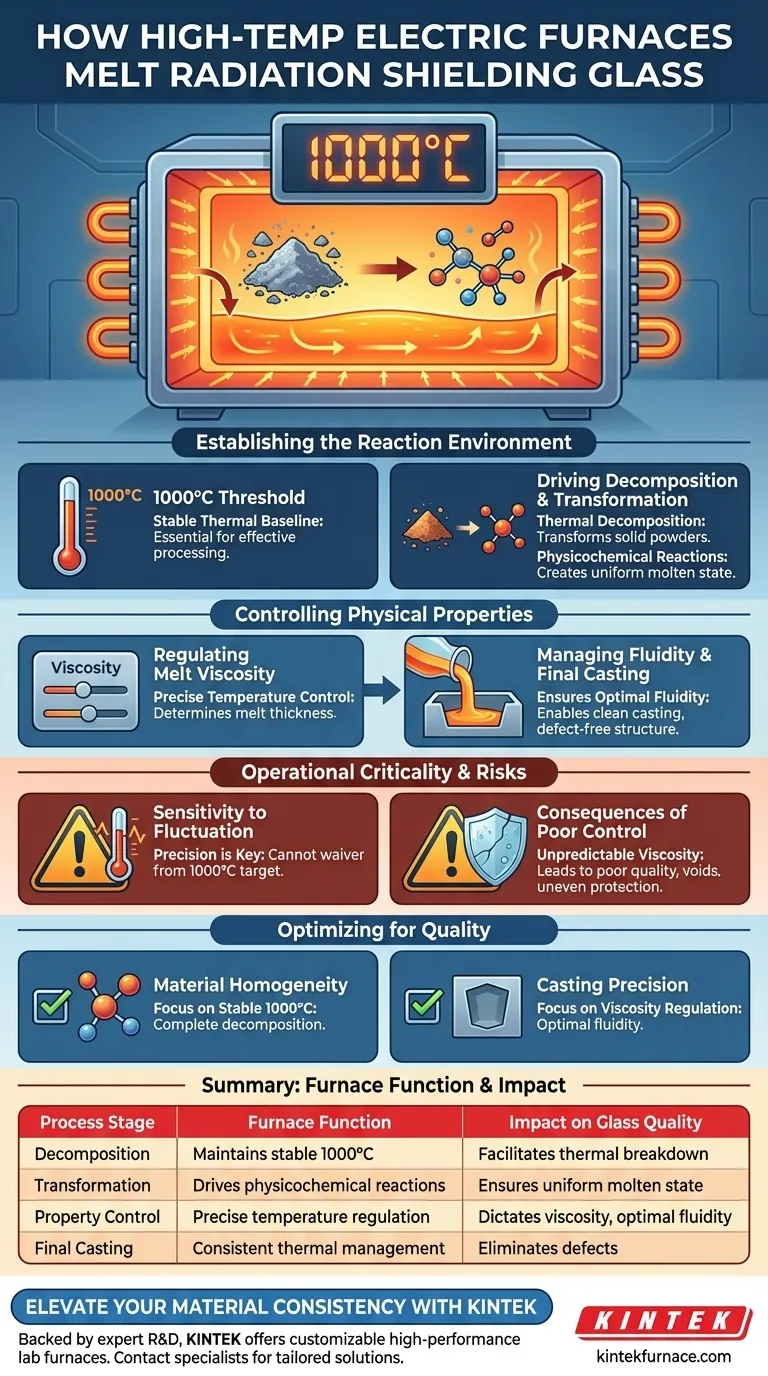

Establishing the Reaction Environment

The 1000°C Threshold

To process radiation shielding glass effectively, a specific thermal baseline is required. The high-temperature electric furnace provides a stable 1000°C environment.

Driving Decomposition

At this temperature, the furnace facilitates the thermal decomposition of raw oxide powders. This breakdown is the first step in transforming solid raw materials into a workable liquid state.

Physicochemical Transformation

Beyond simple melting, the furnace enables complex physicochemical reactions. These reactions are essential for integrating the oxides into a cohesive glass structure, resulting in a completely uniform molten state.

Controlling Physical Properties

Regulating Melt Viscosity

The most critical contribution of the furnace during the melt is precise temperature control. This regulation directly determines the viscosity of the glass melt.

Managing Fluidity

Viscosity dictates fluidity. The furnace ensures the molten glass is fluid enough to move through the production process without premature hardening or stagnation.

Impact on Final Casting

The quality of the final product is a direct result of this thermal management. Proper fluidity ensures that casting and molding are executed cleanly, resulting in a defect-free structure.

Operational Criticality and Risks

Sensitivity to Fluctuation

The process described is highly sensitive to thermal instability. The "trade-off" of using this method is the absolute necessity for precision; the furnace must not waiver from the 1000°C target.

Consequences of Poor Control

If the furnace fails to maintain precise control, viscosity becomes unpredictable. This leads to poor molding quality, potential voids, or uneven protection in the final shielding glass.

Optimizing for Quality

If you are evaluating furnace performance for radiation shielding glass, consider these specific goals:

- If your primary focus is material homogeneity: Ensure the furnace can maintain a stable 1000°C to guarantee complete thermal decomposition of oxide powders.

- If your primary focus is casting precision: Prioritize temperature control systems that tightly regulate viscosity to ensure optimal fluidity during molding.

The high-temperature electric furnace is the critical link between raw chemical potential and a safe, finished glass product.

Summary Table:

| Process Stage | Furnace Function | Impact on Glass Quality |

|---|---|---|

| Decomposition | Maintains stable 1000°C | Facilitates thermal breakdown of oxide powders |

| Transformation | Drives physicochemical reactions | Ensures a completely uniform molten state |

| Property Control | Precise temperature regulation | Dictates viscosity and optimal melt fluidity |

| Final Casting | Consistent thermal management | Eliminates defects during molding and casting |

Elevate Your Material Consistency with KINTEK

Precision in temperature is the difference between a flawed casting and a high-performance radiation shield. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other specialized lab high-temp furnaces—all fully customizable to meet your unique thermal decomposition and melting requirements.

Don't let temperature fluctuations compromise your glass homogeneity. Contact our specialists today to discover how our tailored heating solutions can optimize your production quality and operational efficiency.

Visual Guide

References

- Mohamed Elsafi, Taha A. Hanafy. Experimental study of different oxides in B2O3–ZnO–BaO glass system for gamma-ray shielding. DOI: 10.1038/s41598-025-85230-9

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why are muffle furnaces popular in industrial sectors? Discover Their Key Benefits for Clean, Precise Heating

- What are the common uses of box type electric furnaces in heat treatment processes? Achieve Precise Material Property Control

- How do muffle furnaces enhance efficiency and safety? Boost Your Lab's Performance with Isolated Heating

- How does an industrial-grade box-type high-temperature furnace contribute to the formation of the NaY(WO4)2 crystal phase?

- What core role does a high-temperature box resistance furnace play in the production of doped Nickel Oxide nanopowders?

- What are the key high-temperature applications of a digital muffle furnace? Unlock Precision in Materials Processing

- How does a laboratory muffle furnace contribute to the thermal processing of Ti-Zr-Nb alloy sheets?

- What heat treatment processes can be performed using Box Furnaces? Master Versatile Thermal Processing