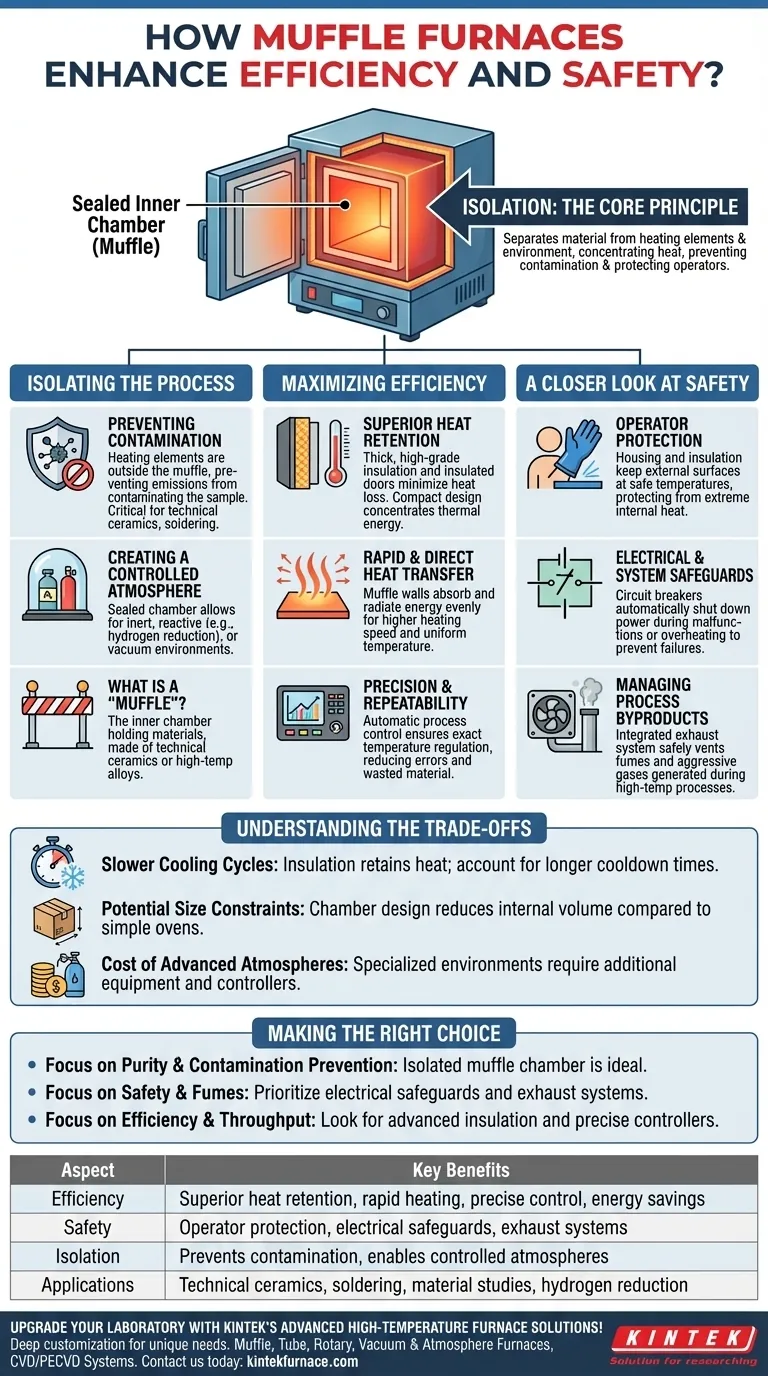

At their core, muffle furnaces enhance efficiency and safety through a single design principle: isolation. By creating a sealed inner chamber, or "muffle," the furnace completely separates the material being heated from the heating elements and the external environment. This ensures heat is concentrated where it's needed and protects both the sample from contamination and the operator from hazards.

The defining feature of a muffle furnace is its chamber-within-a-chamber design. This fundamental separation is the source of its primary benefits, enabling a pure, controlled heating environment that is inherently safer and more energy-efficient than direct-fire designs.

The Core Principle: Isolating the Process

A muffle furnace's unique advantages stem from its physical separation of the workload from the source of heat. This isn't just a minor feature; it is the entire basis of its operation.

What is a "Muffle"?

The "muffle" is the inner chamber that holds the materials. It is constructed from materials like technical ceramics or high-temperature metal alloys.

This chamber acts as a complete barrier, shielding the contents from the electric heating elements that surround it.

Preventing Contamination

Because the heating elements are on the outside of the muffle, any particles or gases they might emit cannot contaminate the sample.

This is critical for processes like producing technical ceramics, studying material properties, or soldering, where even trace amounts of impurities can ruin the outcome.

Creating a Controlled Atmosphere

The sealed muffle chamber makes it possible to maintain a specific controlled atmosphere.

This allows for processes that require inert gases, reactive gases like in a hydrogen reduction furnace, or a vacuum. The furnace provides a self-contained, predictable environment for this work.

How Muffle Furnaces Maximize Efficiency

Efficiency in a muffle furnace is achieved through intelligent heat management, ensuring that energy is used effectively and processes run without waste.

Superior Heat Retention

Muffle furnaces are built with thick, high-grade insulation and insulated doors to minimize heat loss to the surrounding area.

Their compact design means less empty space to heat, concentrating thermal energy on the workload and improving overall energy efficiency.

Rapid and Direct Heat Transfer

The walls of the muffle are designed to absorb energy from the external heating elements and radiate it evenly throughout the chamber.

This design results in a higher heating speed and uniform temperature, ensuring the entire sample is processed consistently.

Precision and Repeatability

By isolating the chamber, the furnace allows for automatic process control and precise temperature regulation. This ensures materials are heated to the exact specification every time, reducing errors, rework, and wasted material.

A Closer Look at Safety Mechanisms

The isolated design and robust construction of muffle furnaces create multiple layers of safety for both the operator and the facility.

Operator Protection

The furnace housing, often made of textured stainless steel, and the heavily insulated chamber walls keep external surfaces at a safe temperature. This protects operators from the extreme internal heat.

Electrical and System Safeguards

Modern muffle furnaces are equipped with circuit breakers that automatically shut down power in the event of a malfunction or overheat. This critical feature prevents catastrophic failures and damage.

Managing Process Byproducts

Many high-temperature processes generate fumes or aggressive gases. An integrated exhaust system is a key safety feature, safely venting these harmful byproducts and maintaining optimal conditions inside the chamber.

Understanding the Trade-offs

While highly effective, the design of a muffle furnace presents certain limitations that are important to understand.

Slower Cooling Cycles

The same excellent insulation that retains heat so efficiently also prevents the furnace from cooling down quickly. Unless a model has a forced cooling feature, you must account for longer cooldown times between cycles.

Potential Size Constraints

The chamber-within-a-chamber design and thick insulation mean that for a given external footprint, the internal working volume of a muffle furnace may be smaller than that of a simpler oven.

Cost of Advanced Atmospheres

A basic muffle furnace provides a clean air environment. Achieving a specialized, controlled atmosphere requires additional gas-handling equipment and controllers, which adds to the system's complexity and cost.

Making the Right Choice for Your Application

Selecting the right features depends entirely on your primary goal.

- If your primary focus is material purity and preventing contamination: The core benefit of the isolated muffle chamber makes this furnace type the ideal choice.

- If your primary focus is operational safety and managing hazardous fumes: Prioritize models with certified electrical safeguards and an integrated exhaust system for ventilation.

- If your primary focus is energy efficiency and throughput: Look for furnaces with advanced ceramic fiber insulation and precise digital temperature controllers for rapid and repeatable cycles.

By mastering the principles of isolation and containment, a muffle furnace delivers precise, repeatable results with uncompromising safety.

Summary Table:

| Aspect | Key Benefits |

|---|---|

| Efficiency | Superior heat retention, rapid heating, precise control, energy savings |

| Safety | Operator protection, electrical safeguards, exhaust systems for fumes |

| Isolation | Prevents contamination, enables controlled atmospheres |

| Applications | Technical ceramics, soldering, material studies, hydrogen reduction |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and safety. Contact us today to discuss how we can support your research and development goals!

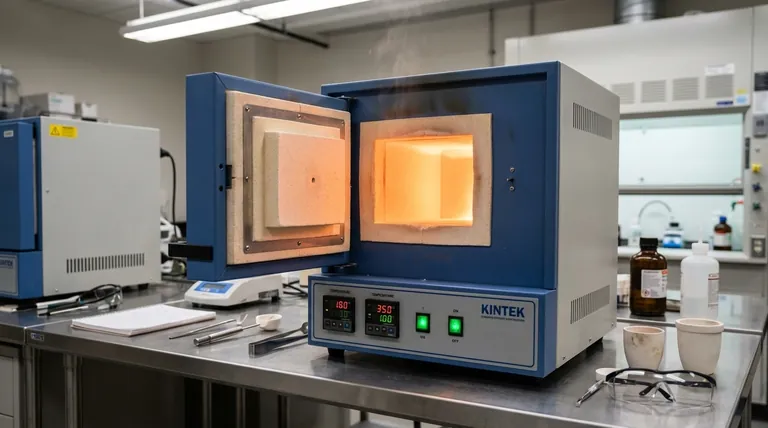

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization