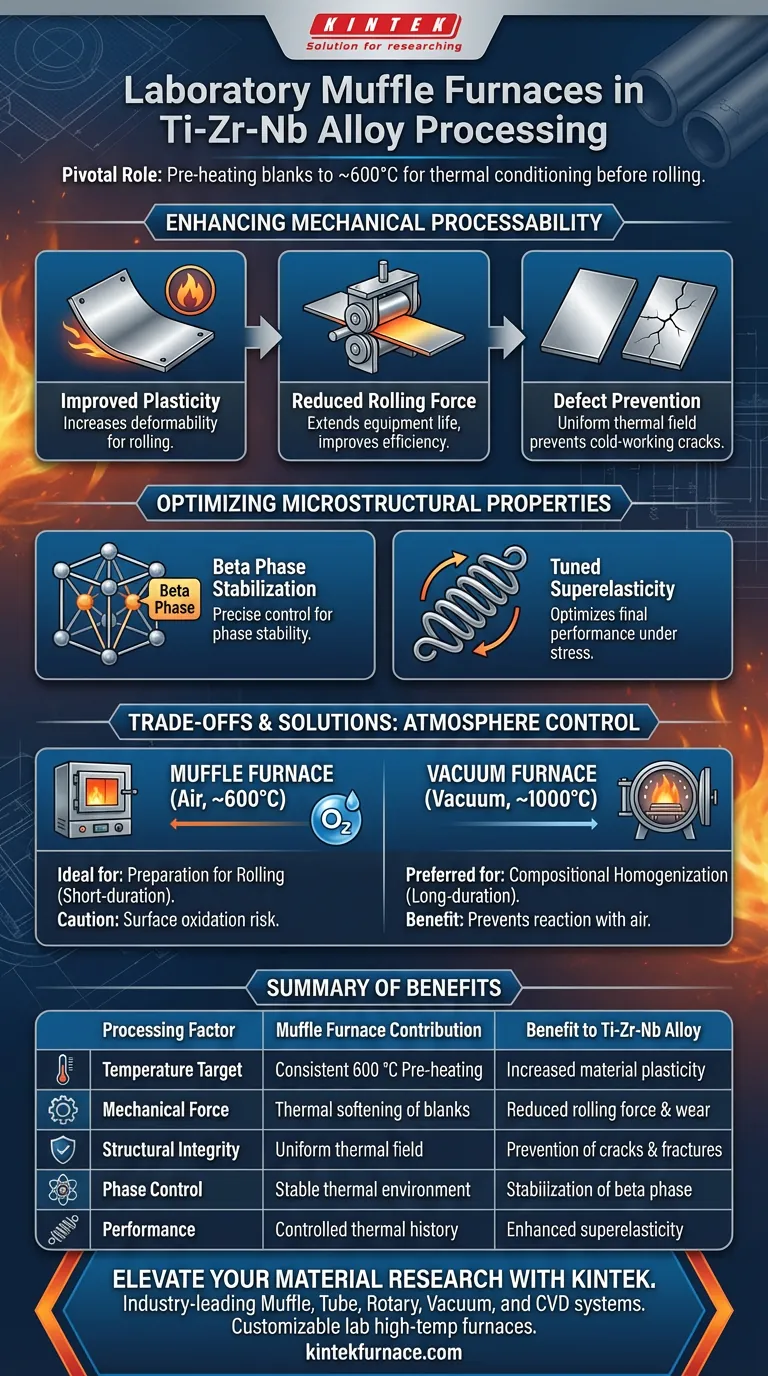

A laboratory muffle furnace plays a pivotal role in the pre-rolling stage of processing Ti-Zr-Nb alloy sheets by providing a stable, high-temperature environment. Specifically, it is utilized to pre-heat alloy blanks to approximately 600 °C, ensuring the material is thermally conditioned for subsequent mechanical deformation.

By establishing a precise thermal field, the muffle furnace optimizes the alloy's plasticity and stabilizes its internal phase structure. This not only prevents structural failures during rolling but also defines the material's final superelastic capabilities.

Enhancing Mechanical Processability

Improving Material Plasticity

The primary function of the muffle furnace in this context is to prepare the alloy for physical deformation.

By pre-heating the Ti-Zr-Nb blanks to 600 °C, the furnace significantly increases the material's plasticity. This thermal softening is a prerequisite for successful rolling operations.

Reduction of Rolling Force

Proper thermal conditioning directly impacts the efficiency of the rolling machinery.

When the alloy maintains optimal plasticity, the force required to deform the sheet is substantially reduced. This extends the lifespan of rolling equipment and improves energy efficiency during processing.

Prevention of Structural Defects

Temperature stability is the main defense against material failure.

Without the precise pre-heating provided by the muffle furnace, the alloy is susceptible to cold-working cracks. The furnace ensures a uniform thermal field that mitigates these stress-induced fractures.

Optimizing Microstructural Properties

Stabilization of the Beta Phase

Beyond simple heating, the muffle furnace acts as a tool for phase control.

Precise temperature regulation is critical for stabilizing the metastable beta phase within the Ti-Zr-Nb alloy. This phase stability is the microstructural foundation for the alloy's advanced performance characteristics.

Tuning Superelastic Performance

The ultimate goal of this thermal processing is functional performance.

By controlling the thermal history of the blank, the muffle furnace helps optimize the superelasticity of the final sheet. This ensures the material behaves predictably under stress in its end-use application.

Understanding the Trade-offs

Atmosphere Control Limitations

While effective for pre-heating, standard muffle furnaces typically operate with an air atmosphere.

Ti-Zr-Nb alloys are highly reactive to oxygen at elevated temperatures. Extended exposure in a standard muffle furnace can lead to surface oxidation or embrittlement.

Suitability for Process Stages

It is crucial to distinguish between pre-heating and long-term homogenization.

For short-duration rolling preparation, the muffle furnace is ideal. However, for long-duration treatments like homogenization annealing (often at 1000 °C), a vacuum resistance furnace is preferred to prevent reaction with air and ensure chemical consistency.

Making the Right Choice for Your Goal

To maximize the quality of your Ti-Zr-Nb alloy sheets, align your furnace selection with your specific processing stage:

- If your primary focus is Preparation for Rolling: Utilize a muffle furnace at ~600 °C to maximize plasticity and minimize rolling force.

- If your primary focus is Compositional Homogenization: Choose a vacuum resistance furnace to eliminate dendritic segregation without risking oxidation.

Precise thermal management is the critical link between a raw alloy blank and a high-performance, crack-free superelastic component.

Summary Table:

| Processing Factor | Muffle Furnace Contribution | Benefit to Ti-Zr-Nb Alloy |

|---|---|---|

| Temperature Target | Consistent 600 °C Pre-heating | Increased material plasticity for rolling |

| Mechanical Force | Thermal softening of blanks | Reduced rolling force and equipment wear |

| Structural Integrity | Uniform thermal field | Prevention of cold-working cracks and fractures |

| Phase Control | Stable thermal environment | Stabilization of the metastable beta phase |

| Performance | Controlled thermal history | Enhanced superelasticity in the final sheet |

Elevate Your Material Research with KINTEK

Precise thermal management is the difference between material failure and high-performance innovation. KINTEK provides industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems, all engineered to meet the rigorous demands of advanced metallurgy.

Whether you are processing reactive Ti-Zr-Nb alloys or developing new superelastic components, our expert R&D and manufacturing team can deliver customizable lab high-temp furnaces tailored to your exact specifications.

Ready to optimize your thermal processing? Contact KINTEK today to discuss your project requirements with our technical specialists.

Visual Guide

References

- K. V. Sergienko, A. G. Kolmakov. Physical and Mechanical Properties of Ti-Zr-Nb Alloys for Medical Use. DOI: 10.3390/met14111311

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the proper procedure after completing an experiment with the muffle furnace? Ensure Safety and Accuracy in Your Lab

- What role does a laboratory high-temperature muffle furnace play in converting calcified pollen into bioceramics?

- What is the function of a muffle furnace in preparing expanded graphite? Achieve High-Efficiency PCM Carriers

- Why is a muffle furnace essential for Ni and Zn-doped MgO nanoparticles? Master Calcination for Pure Phase Synthesis

- What are the key features of the muffle furnace's design? Discover Precision Heating and Safety

- What are the main structural components of a box furnace? Essential Guide for Efficient Material Processing

- How is a laboratory box furnace utilized in the production of nanomaterials? Mastering Hydrothermal Synthesis

- What is the function of a muffle furnace during Cu–Ce/HZSM-5 production? Optimize Calcination & Regeneration Stages