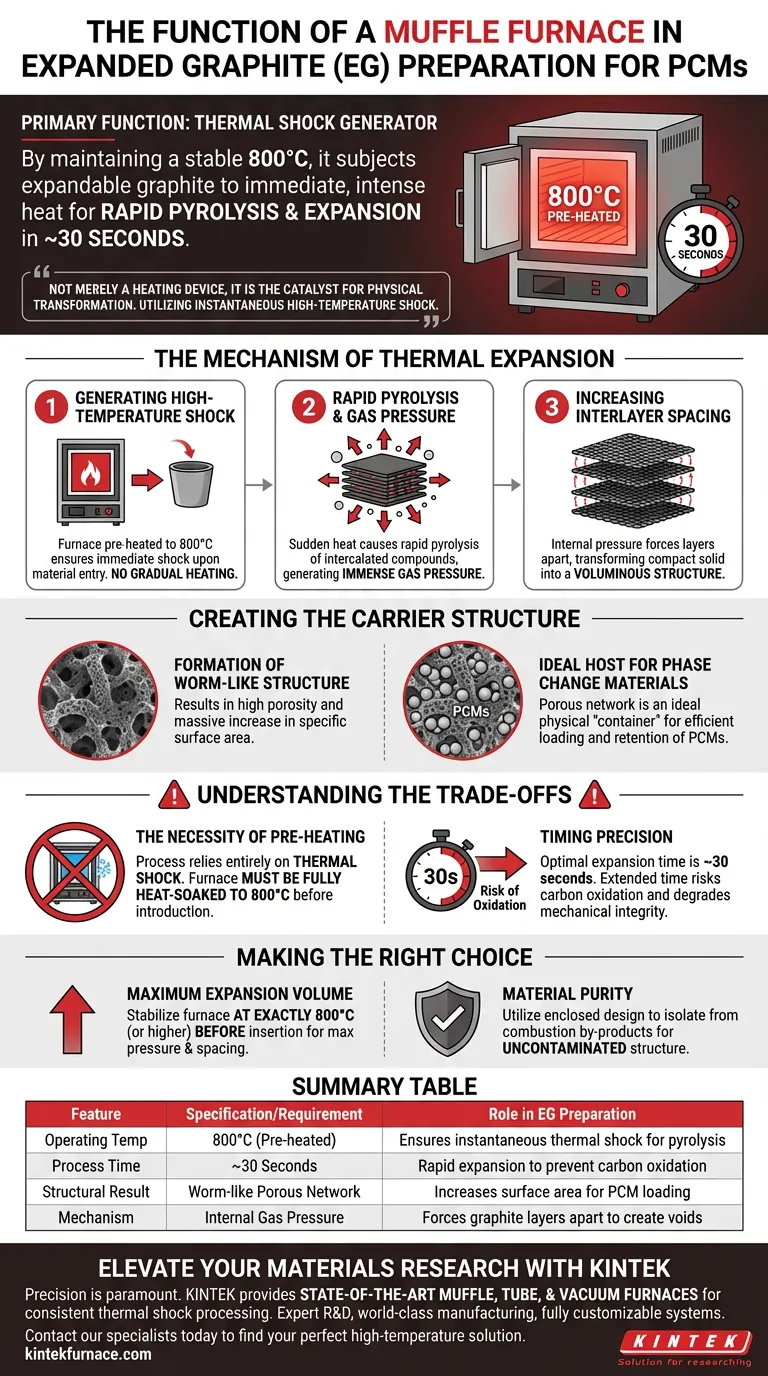

The primary function of a muffle furnace in this context is to act as a thermal shock generator. By maintaining a stable environment at 800°C, it subjects expandable graphite to immediate, intense heat, triggering rapid pyrolysis and expansion within approximately 30 seconds.

The muffle furnace is not merely a heating device; it is the catalyst for a physical transformation. It utilizes instantaneous high-temperature shock to convert dense graphite layers into a highly porous, worm-like structure essential for holding phase change materials.

The Mechanism of Thermal Expansion

The preparation of expanded graphite (EG) relies on a specific sequence of physical reactions that the muffle furnace facilitates.

Generating High-Temperature Shock

Unlike processes that require gradual heating, EG preparation demands an instantaneous high-temperature environment. The muffle furnace is pre-heated to 800°C to ensure that as soon as the material enters, it undergoes immediate thermal shock.

Rapid Pyrolysis and Gas Pressure

This sudden exposure to heat causes the intercalated compounds within the graphite to undergo rapid pyrolysis. This reaction generates immense gas pressure between the graphite layers almost instantly.

Increasing Interlayer Spacing

The internal pressure forces the graphite layers apart. This significantly increases the interlayer spacing, transforming the material from a compact solid into a voluminous structure.

Creating the Carrier Structure

The ultimate goal of using the muffle furnace is to engineer a physical space capable of hosting other substances.

Formation of Worm-like Structure

The expansion process results in a distinct worm-like porous structure. This architecture is characterized by high porosity and a massive increase in specific surface area compared to the raw material.

Ideal Host for Phase Change Materials

This newly created porous network serves as an ideal physical "container." The expanded voids allow for the efficient loading and retention of phase change materials (PCMs), which is the ultimate objective of the preparation process.

Understanding the Trade-offs

While the muffle furnace is effective, understanding its operational constraints is vital for consistent results.

The Necessity of Pre-heating

The process relies entirely on thermal shock, not gradual heating. A common pitfall is placing materials in a cold furnace and ramping the temperature up; this will fail to generate the rapid gas pressure required for proper expansion. The furnace must be fully heat-soaked to 800°C before the material is introduced.

Timing Precision

The primary reference notes an expansion time of roughly 30 seconds. Extended residence time beyond this window yields diminishing returns and may risk oxidation of the carbon structure, potentially degrading the carrier's mechanical integrity.

Making the Right Choice for Your Goal

To ensure optimal expanded graphite preparation, align your furnace usage with your specific project needs.

- If your primary focus is Maximum Expansion Volume: Ensure the furnace is stabilized at exactly 800°C (or slightly higher) before insertion to maximize the pressure differential and interlayer spacing.

- If your primary focus is Material Purity: Utilize the muffle furnace's enclosed design to isolate the graphite from fuel combustion by-products, ensuring the porous structure remains uncontaminated for PCM loading.

The muffle furnace converts thermal energy into structural utility, turning raw graphite into a sophisticated sponge for thermal energy storage.

Summary Table:

| Feature | Specification/Requirement | Role in EG Preparation |

|---|---|---|

| Operating Temp | 800°C (Pre-heated) | Ensures instantaneous thermal shock for pyrolysis |

| Process Time | ~30 Seconds | Rapid expansion to prevent carbon oxidation |

| Structural Result | Worm-like Porous Network | Increases surface area for PCM loading |

| Mechanism | Internal Gas Pressure | Forces graphite layers apart to create voids |

Elevate Your Materials Research with KINTEK

Precision is paramount when preparing expanded graphite carriers. KINTEK provides state-of-the-art muffle, tube, and vacuum furnaces designed to deliver the stable, high-temperature environments essential for consistent thermal shock processing.

Backed by expert R&D and world-class manufacturing, our systems are fully customizable to meet the unique demands of your lab. Whether you are developing phase change materials or advanced carbon structures, KINTEK offers the thermal reliability you need to succeed.

Ready to optimize your thermal expansion process? Contact our specialists today to find the perfect high-temperature solution for your laboratory.

Visual Guide

References

- Jin Tang, Cuiping Wang. Thermal Performance Improvement of Composite Phase-Change Storage Material of Octanoic Acid–Tetradecanol by Modified Expanded Graphite. DOI: 10.3390/en17174311

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a secondary annealing treatment in a muffle furnace necessary for coated ceramic sensor components?

- What are the key specifications of a typical muffle furnace? Essential Guide for Lab Efficiency

- What are the common uses of muffle furnaces? Essential for Material Analysis, Heat Treatment, and Synthesis

- What role does a muffle furnace play in BCZY712 electrolyte powder production? Achieve Perfect Phase Purity

- Why is precise temperature control important in crucible furnaces? Ensure Quality & Efficiency in Thermal Processing

- What role does a muffle furnace play in Al2O3/PTFE composites? Optimize Sintering for Superior Performance

- What conditions does a muffle furnace provide for carbon paper electrodes? Optimize Your Electrode Surface Chemistry

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength