In short, precise temperature control is the single most important factor for ensuring the quality, consistency, and structural integrity of materials processed in a crucible furnace. It moves the process from an art to a science, guaranteeing that the final product meets exact specifications by preventing defects and ensuring the desired chemical and physical properties are achieved.

The core issue is that temperature is not just about melting; it is a critical process variable. Every degree of deviation can alter a material's final composition, introduce structural flaws, and lead to wasted energy and materials, making precise control fundamental to both quality and operational efficiency.

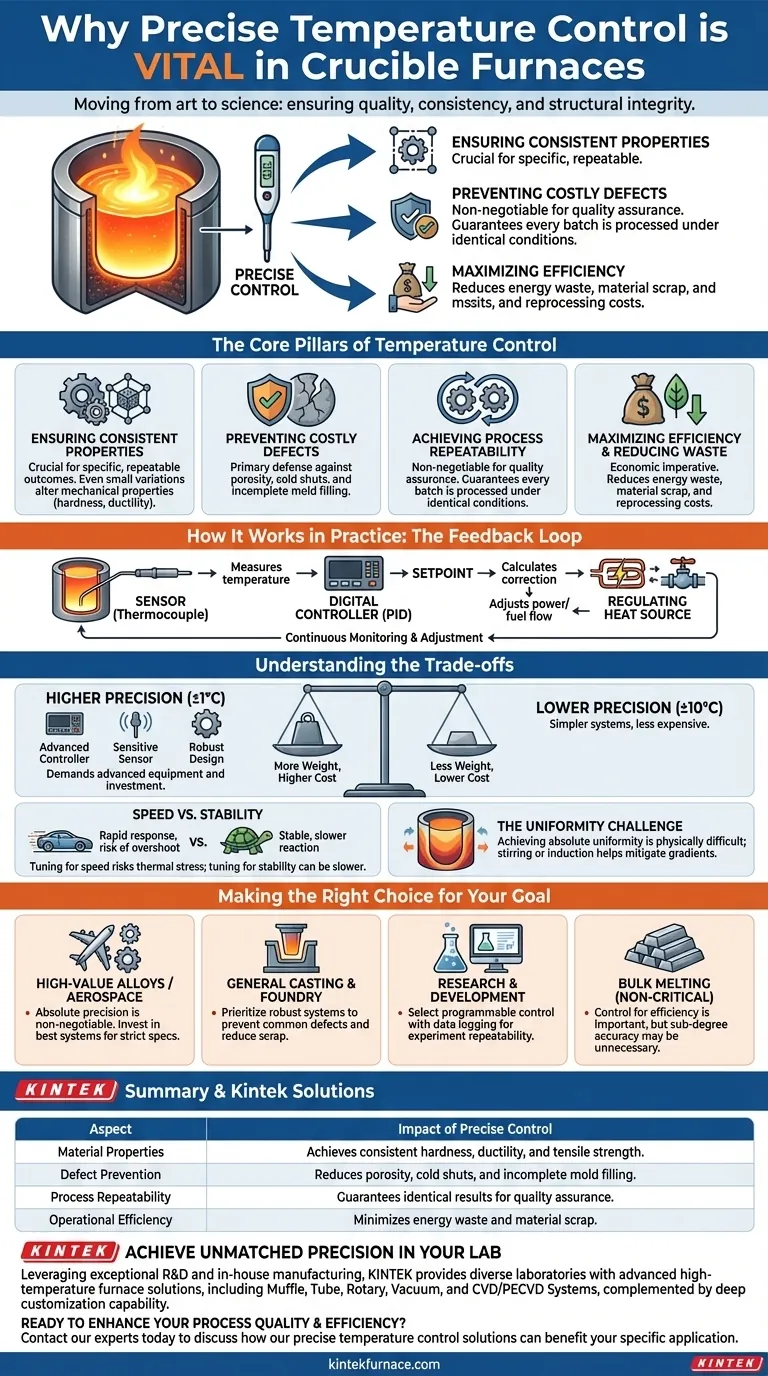

The Core Pillars of Temperature Control

Understanding why precision matters requires looking at how temperature directly impacts the material at a microscopic and macroscopic level. It influences everything from chemical composition to the final casted shape.

Ensuring Consistent Material Properties

Precise temperature management is crucial for achieving a specific, repeatable outcome. For metal alloys, even small temperature variations can significantly alter the final mechanical properties, such as hardness, ductility, and tensile strength.

Overheating can burn off critical alloying elements, changing the material's composition. Underheating can result in an incomplete reaction or an improper crystalline structure, failing to produce the desired characteristics.

Preventing Costly Defects

Many common casting and material defects are a direct result of poor temperature control. Maintaining a stable, correct temperature is your primary defense against these issues.

Defects like porosity are often caused by dissolved gases that come out of the solution as the metal cools. Incorrect pouring temperatures exacerbate this problem. Likewise, temperatures that are too low can cause the material to solidify prematurely, leading to incomplete mold filling and "cold shuts."

Achieving Process Repeatability

For both industrial manufacturing and scientific research, the ability to replicate results is non-negotiable. Precise temperature control ensures that every batch is processed under identical thermal conditions.

This repeatability is the foundation of quality assurance. It guarantees that the first part produced is identical to the last, a critical requirement for industries like aerospace, medical, and electronics.

Maximizing Efficiency and Reducing Waste

Temperature control is also an economic imperative. Overheating a furnace is a significant waste of energy, driving up operational costs with no added benefit to the product.

Furthermore, by preventing defects and ensuring complete mold filling, precise control minimizes the amount of scrapped material. This reduces waste and the energy required for reprocessing, leading to a more efficient and sustainable operation.

How Temperature Control Works in Practice

Modern furnaces achieve this precision through a sophisticated feedback loop. This system constantly measures and adjusts the energy input to hold the temperature at a desired setpoint.

The Sensor and Controller Loop

The heart of the system is a thermocouple, a robust sensor placed inside the furnace to measure the real-time temperature of the material or chamber.

This temperature reading is sent to a digital controller (often a PID controller), which compares the actual temperature to the user-defined setpoint. It then calculates the necessary correction.

Regulating the Heat Source

Based on the controller's calculation, the system adjusts the power delivered to the heat source. In an electric furnace, this means regulating the current flowing to the heating elements.

In a gas-fired furnace, the controller manipulates valves that manage the flow of fuel and air to the burners, increasing or decreasing the flame to maintain the target temperature.

Understanding the Trade-offs

While essential, achieving high precision involves balancing cost, performance, and physical limitations. No system is perfect, and understanding its constraints is key to effective use.

The Cost of Precision

Higher precision demands more advanced equipment. A system that can hold a temperature within ±1°C requires a more sensitive thermocouple, a more sophisticated PID controller, and potentially a more robust furnace design than one that only needs to be accurate to ±10°C.

Speed vs. Stability

A control system must be "tuned." A system tuned for a rapid response might reach the setpoint quickly but is at risk of overshooting it, causing thermal stress. A system tuned for stability will avoid overshooting but may react more slowly to temperature changes.

The Challenge of Uniformity

Even with a perfect controller, achieving absolute temperature uniformity throughout a large crucible of molten metal is physically difficult. There will always be a slight temperature gradient between the material near the heating elements and the material in the center. Stirring or induction currents can help mitigate this, but it remains a key consideration.

Making the Right Choice for Your Goal

The required level of precision is directly tied to your application. Use your end goal to determine how to prioritize temperature control in your process.

- If your primary focus is high-value alloys or aerospace parts: Absolute precision is non-negotiable. Invest in the best possible control system to meet strict metallurgical specifications and prevent failure.

- If your primary focus is general casting and foundry work: Prioritize a robust system that prevents common defects like porosity and ensures good mold flow to reduce scrap rates.

- If your primary focus is research and development: Select a system with programmable control and data logging to ensure experiment repeatability and provide accurate data for analysis.

- If your primary focus is bulk melting of non-critical materials: Control is still important for energy efficiency and preventing gross overheating, but sub-degree accuracy may be an unnecessary expense.

Ultimately, precise temperature control is the foundation upon which predictable, high-quality, and efficient thermal processing is built.

Summary Table:

| Aspect | Impact of Precise Temperature Control |

|---|---|

| Material Properties | Achieves consistent hardness, ductility, and tensile strength. |

| Defect Prevention | Reduces porosity, cold shuts, and incomplete mold filling. |

| Process Repeatability | Guarantees identical results for quality assurance. |

| Operational Efficiency | Minimizes energy waste and material scrap. |

Achieve Unmatched Precision in Your Lab

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Ready to enhance your process quality and efficiency? Contact our experts today to discuss how our precise temperature control solutions can benefit your specific application.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis