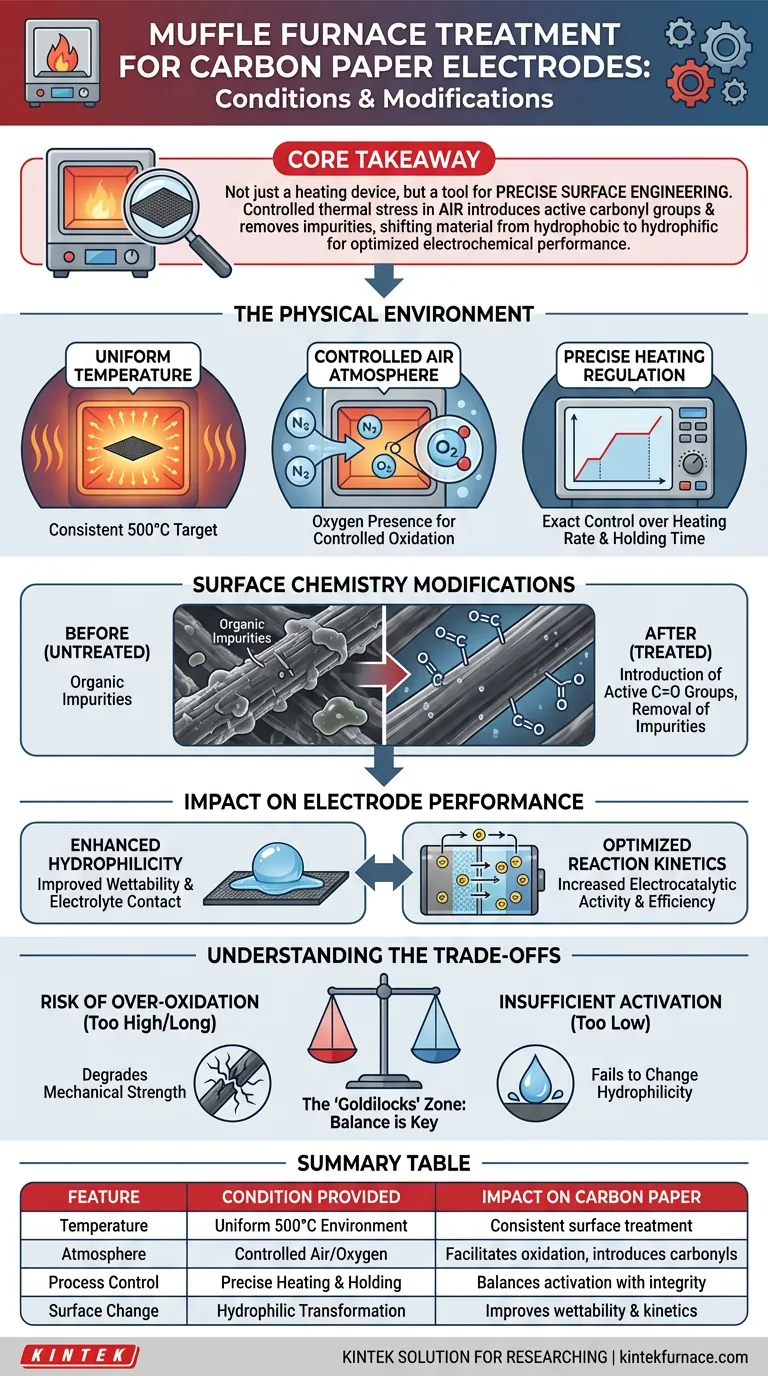

A muffle furnace provides a uniform, high-temperature environment specifically designed to facilitate controlled oxidation in an air atmosphere. For carbon paper electrodes, this typically involves maintaining a stable temperature around 500 degrees Celsius while offering precise regulation over heating rates and holding times to alter surface chemistry without destroying the material.

Core Takeaway The muffle furnace is not merely a heating device; it is a tool for precise surface engineering. By subjecting carbon paper to controlled thermal stress in air, it introduces active carbonyl groups and removes impurities, fundamentally shifting the material from hydrophobic to hydrophilic to optimize electrochemical performance.

The Physical Environment

To understand how a muffle furnace modifies carbon paper, one must look at the specific environmental conditions it creates.

Uniform Temperature Distribution

The furnace creates a highly uniform temperature field, typically targeting 500 degrees Celsius. This uniformity ensures that the entire surface area of the carbon paper is treated equally, preventing uneven modification that could lead to inconsistent battery performance.

Controlled Air Atmosphere

Unlike inert atmosphere furnaces, the muffle furnace utilizes an air atmosphere during this process. The presence of oxygen is a functional requirement, not a byproduct, as it is necessary to induce the specific chemical reactions required for surface activation.

Precise Heating Regulation

The equipment allows for exact control over the heating rate and holding time. Whether ramping up slowly or holding a steady temperature, these parameters dictate the depth and extent of the surface modification.

Surface Chemistry Modifications

The thermal environment provided by the muffle furnace drives specific molecular changes on the carbon fibers.

Introduction of Active Functional Groups

The combination of high heat and oxygen induces controlled oxidation on the carbon fiber surfaces. This process introduces oxygen-containing functional groups, specifically carbonyl (C=O) groups, which are critical for chemical reactivity.

Removal of Organic Impurities

The high operating temperature effectively burns off residual organic impurities on the fiber surface. This cleansing process exposes the raw carbon structure, ensuring that subsequent chemical reactions are not hindered by contaminants.

Impact on Electrode Performance

The physical and chemical changes induced by the furnace directly translate to improved functional characteristics of the electrode.

Enhanced Hydrophilicity

Untreated carbon paper is naturally hydrophobic (water-repelling). The thermal treatment significantly improves wettability, allowing the electrolyte to make efficient contact with the electrode surface.

Optimized Reaction Kinetics

The introduction of active functional groups increases the electrocatalytic activity of the material. This optimization is particularly vital for applications like vanadium redox flow batteries, where reaction kinetics determine overall efficiency.

Understanding the Trade-offs

While thermal treatment is beneficial, precise control is essential to avoid detrimental effects.

Risk of Over-Oxidation

If the temperature is too high or the holding time is too long, the carbon fibers may suffer from excessive oxidation. This can degrade the mechanical strength of the paper, making it brittle and unsuitable for use.

The Balance of Activation

Insufficient heating will fail to introduce enough functional groups to change the material's hydrophilicity. The process requires a "Goldilocks" zone—enough heat to activate the surface, but not enough to compromise structural integrity.

Making the Right Choice for Your Goal

When configuring a muffle furnace for carbon paper treatment, align your parameters with your specific electrochemical objectives.

- If your primary focus is increasing reaction speed: Prioritize a temperature protocol (e.g., 500°C) known to maximize the density of carbonyl (C=O) groups to boost electrocatalytic activity.

- If your primary focus is electrolyte wetting: Ensure the process allows for sufficient oxidation time to completely shift the surface property from hydrophobic to hydrophilic.

Mastering the conditions of the muffle furnace allows you to turn generic carbon paper into a high-performance interface for advanced energy storage.

Summary Table:

| Feature | Condition Provided | Impact on Carbon Paper |

|---|---|---|

| Temperature | Uniform 500°C Environment | Ensures consistent surface treatment across the material |

| Atmosphere | Controlled Air/Oxygen | Facilitates oxidation to introduce active carbonyl groups |

| Process Control | Precise Heating & Holding Time | Balances surface activation with material structural integrity |

| Surface Change | Hydrophilic Transformation | Improves electrolyte wettability and reaction kinetics |

Elevate Your Materials Research with KINTEK

Unlock the full potential of your carbon paper electrodes with KINTEK’s high-precision thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique laboratory requirements. Whether you are optimizing vanadium redox flow batteries or engineering advanced catalysts, our furnaces provide the temperature uniformity and atmospheric control essential for superior results.

Ready to transform your thermal treatment process? Contact us today to discuss your custom furnace needs!

Visual Guide

References

- Kavin Teenakul, Amirreza Khataee. Treatment of carbon electrodes with Ti<sub>3</sub>C<sub>2</sub>T<sub><i>x</i></sub> MXene coating and thermal method for vanadium redox flow batteries: a comparative study. DOI: 10.1039/d4ra01380h

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why use a high-temp box resistance furnace for Ca2.5Ag0.3Sm0.2Co4O9 sintering? Ensure Phase Purity and Alignment

- What applications does a muffle furnace have in coal quality analysis? Essential for Precise Coal Testing

- Why is a laboratory high-temperature oven necessary for hierarchical carbon fibers? Stabilize Residues for Success

- What maintenance checks are required for a muffle furnace? Ensure Safety and Accuracy in Your Lab

- What heating systems can Muffle Furnaces use? Choose Electric or Gas for Optimal Performance

- How is a muffle furnace utilized in the thermal oxidation of hematite nanostructures? Achieve Precise Phase Control

- How is a muffle furnace utilized in the post-treatment for B-doped SiC nanowires? Ensure High Purity & Integrity

- What is the role of a muffle furnace in the calcination of Co@BaAl2O4-x catalyst? Key Steps for Precision Synthesis