To properly maintain a muffle furnace, you must perform regular checks on its electrical wiring, temperature sensor (thermocouple), and controller. It is also critical to follow specific procedural maintenance, such as drying the furnace before its first use or after long periods of inactivity, to ensure safe and accurate operation. These actions prevent equipment damage, ensure user safety, and guarantee reliable experimental results.

Muffle furnace maintenance is not merely a checklist of periodic repairs; it is a proactive system of inspection and procedural discipline. The goal is to ensure operational safety, maintain temperature accuracy, and extend the functional life of the equipment.

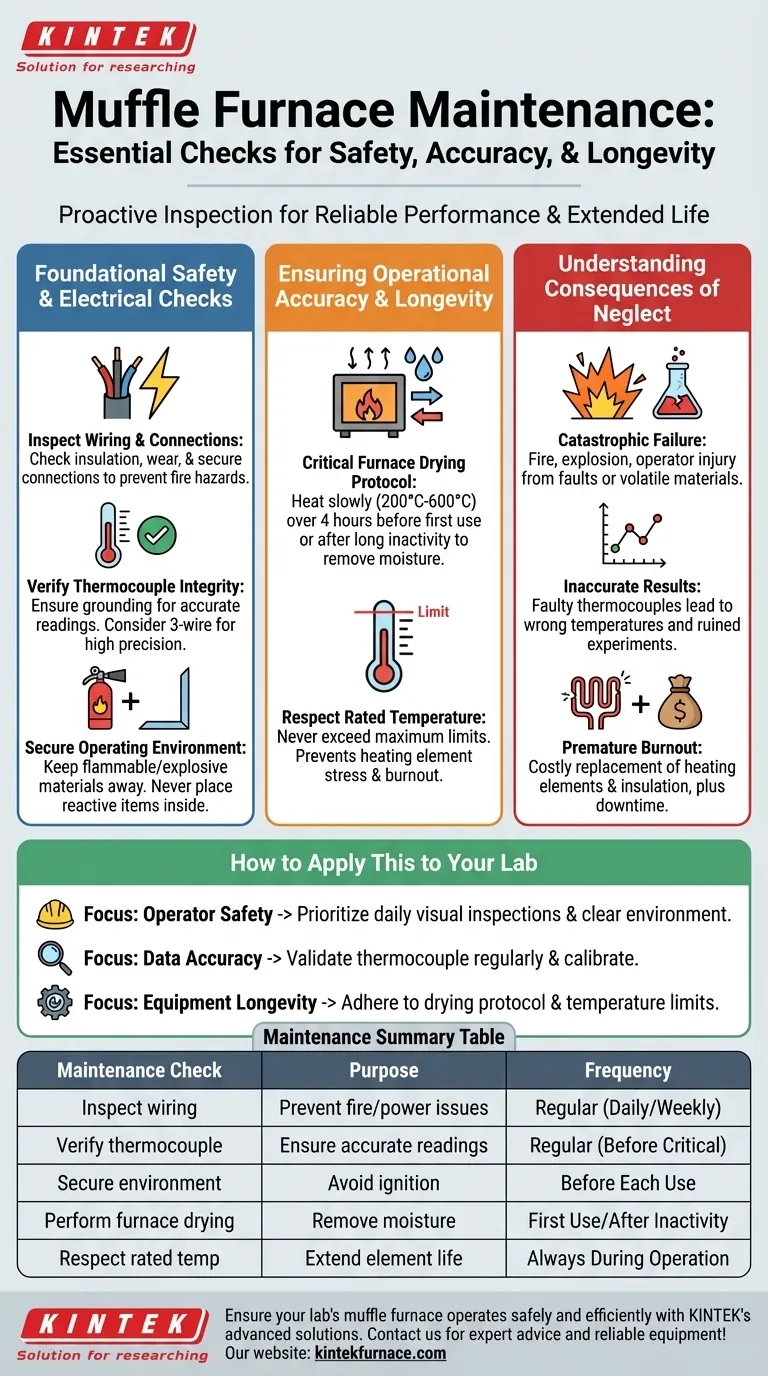

Foundational Safety and Electrical Checks

The most frequent and critical maintenance tasks revolve around ensuring the furnace's electrical integrity and the safety of its immediate environment. These checks prevent the most common causes of accidents and equipment failure.

Inspecting Wiring and Connections

All wiring for the furnace and its controller must be inspected regularly. Look for signs of wear, brittleness, or damage to the insulation.

Damaged wiring is a significant fire hazard and can lead to short circuits that damage the controller or heating elements. A secure connection is essential for consistent power delivery.

Verifying the Thermocouple's Integrity

The thermocouple is your only source of truth for the internal temperature. Its condition is paramount for both safety and accuracy.

Ensure the thermocouple is well-grounded to prevent electrical noise from causing erroneous temperature readings. For applications requiring high precision, using a three-wire thermocouple can further reduce measurement errors.

Securing the Operating Environment

The area around the muffle furnace must be kept clear of all flammable and explosive materials. A high-temperature furnace is a potent ignition source.

Never place any explosive, volatile, or dangerously reactive materials inside the furnace itself. This can lead to uncontrolled pressure buildup, explosions, and catastrophic failure.

Ensuring Operational Accuracy and Longevity

Beyond daily safety checks, certain procedures are vital for the long-term health and accuracy of the furnace. These are less frequent but equally important.

The Critical Furnace Drying Protocol

Before using a muffle furnace for the very first time, or after it has been shut down for a long period, it must be dried. This process removes accumulated moisture from the insulating materials.

To do this, heat the furnace slowly over four hours to a temperature between 200°C and 600°C. Skipping this step can cause steam to form within the insulation, potentially cracking the furnace chamber or damaging the heating elements due to rapid thermal change.

Respecting the Rated Temperature

Never operate the furnace above its maximum rated temperature. Doing so puts extreme stress on the heating elements, significantly shortening their lifespan and risking burnout.

The PID (Proportional-Integral-Derivative) controller is designed to precisely regulate temperature, but it cannot protect the hardware if the setpoint exceeds the design limits of the heating elements.

Understanding the Consequences of Neglect

Failing to perform these checks has direct and serious consequences. Understanding these risks underscores the importance of a consistent maintenance routine.

The Risk of Catastrophic Failure

The most severe risk is operator injury or facility damage. An electrical fault can cause a fire, and heating volatile materials can cause an explosion. These are not theoretical risks; they are the direct result of neglecting basic safety protocols.

The Cost of Inaccurate Results

A faulty or poorly grounded thermocouple provides incorrect temperature data to the controller. This can lead to the furnace running hundreds of degrees hotter or colder than the display indicates, completely invalidating experimental results and ruining samples.

The Expense of Premature Burnout

Skipping the drying procedure or consistently exceeding the maximum temperature will degrade and ultimately destroy the core components of the furnace. The cost of replacing heating elements and refractory insulation is substantial and results in significant equipment downtime.

How to Apply This to Your Lab

Your maintenance strategy should align with your operational priorities. Use these guidelines to structure your approach.

- If your primary focus is operator safety: Prioritize daily visual inspections of all wiring and ensure the area is clear of combustible materials before every use.

- If your primary focus is data accuracy: Regularly validate your thermocouple's condition and grounding, and consider periodic calibration checks against a known standard.

- If your primary focus is equipment longevity: Strictly adhere to the initial drying protocol and never exceed the furnace's maximum rated temperature.

A disciplined approach to maintenance is the single most effective way to ensure your muffle furnace remains a safe, reliable, and long-lasting asset.

Summary Table:

| Maintenance Check | Purpose | Frequency |

|---|---|---|

| Inspect wiring and connections | Prevent fire hazards and power issues | Regular (e.g., daily or weekly) |

| Verify thermocouple integrity | Ensure accurate temperature readings | Regular (e.g., before critical experiments) |

| Secure operating environment | Avoid ignition of flammable materials | Before each use |

| Perform furnace drying | Remove moisture to prevent damage | First use or after long inactivity |

| Respect rated temperature | Extend heating element life | Always during operation |

Ensure your lab's muffle furnace operates safely and efficiently with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we offer high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet your unique needs. Contact us today for expert advice and reliable equipment!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?