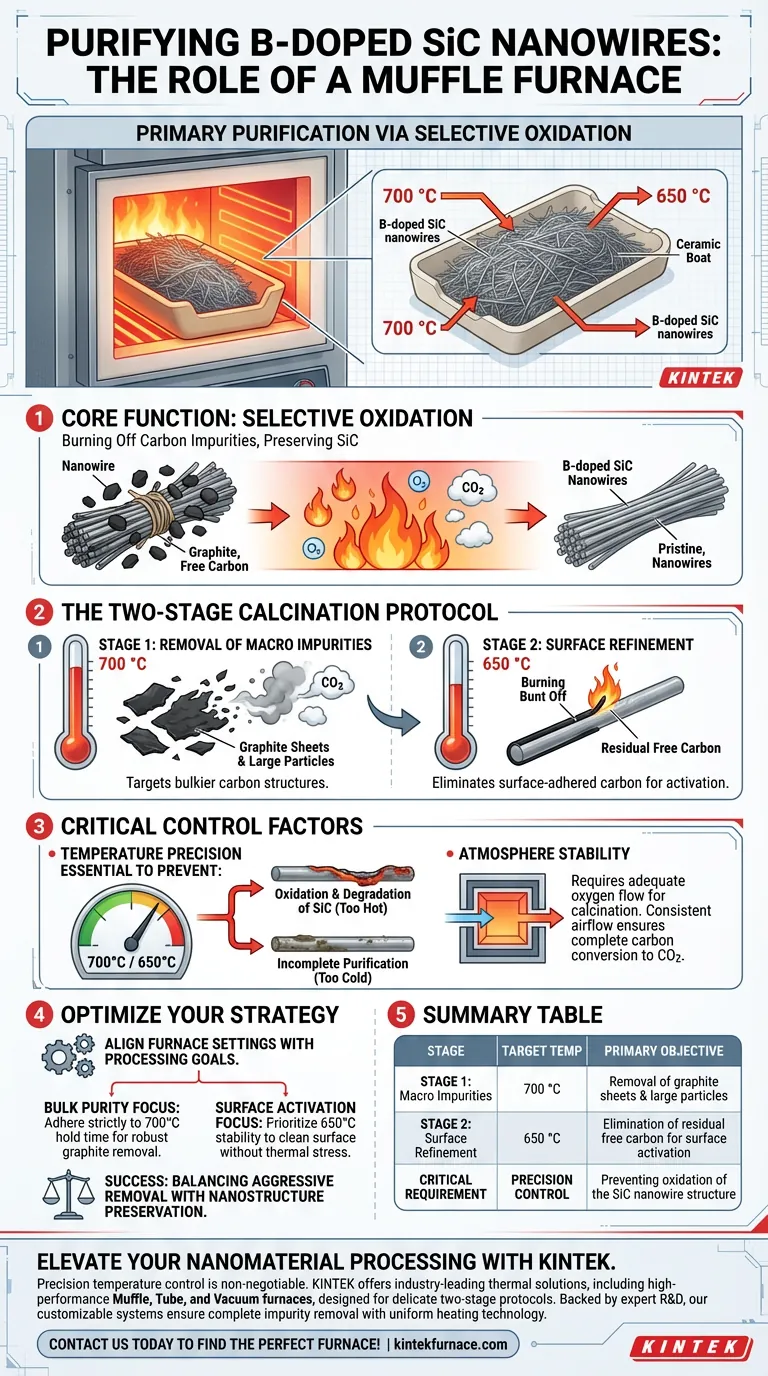

A muffle furnace serves as the primary purification instrument during the post-treatment of Boron-doped Silicon Carbide (SiC) nanowires. It is utilized to execute a precise, two-stage calcination process that selectively oxidizes carbon-based impurities without compromising the structural integrity of the nanowires themselves.

The core function of the muffle furnace in this context is selective oxidation. By leveraging specific temperature thresholds—700°C and 650°C—the furnace effectively burns off graphite and free carbon contaminants while leaving the thermally stable SiC nanowires intact.

The Purification Protocol

The effectiveness of this treatment relies on a distinct, two-step thermal cycle. The muffle furnace provides the stable, industrial-grade environment necessary to maintain these specific temperatures for the required duration.

Stage 1: Removal of Macro Impurities

The first phase of the post-treatment involves heating the material to 700 °C.

At this temperature, the furnace environment facilitates the oxidation of bulkier carbon structures. Specifically, this stage targets and removes graphite sheets and large particle impurities that may have formed alongside the nanowires during synthesis.

Stage 2: Surface Refinement

Following the initial burn-off, the temperature is adjusted to 650 °C for the second stage of calcination.

This lower-temperature phase is critical for cleaning the nanowire interface. It focuses on eliminating residual free carbon that adheres to the surface of the nanowires. Removing this layer is essential for exposing the active surface area of the B-doped SiC.

Precision and Structural Integrity

The defining advantage of using a muffle furnace for this process is temperature uniformity.

SiC nanowires are robust, but they can be sensitive to extreme thermal fluctuations or excessive oxidation. The furnace ensures that the oxidation of carbonaceous impurities occurs efficiently, yet the temperature remains within a safe window that prevents damage to the SiC nanowire structure itself.

Critical Control Factors

While the process is straightforward, the operational precision of the muffle furnace is the variable that determines success or failure.

The Risk of Temperature Deviation

Precise control is not merely a feature; it is a requirement. If the furnace temperature drifts significantly above the target range, you risk oxidizing the SiC nanowires themselves, degrading their electrical and mechanical properties.

Conversely, if the temperature drops below the optimal calcination points, the carbon impurities will not fully decompose. This results in "dirty" nanowires with reduced performance characteristics in practical applications.

Atmosphere Stability

The muffle furnace isolates the workload from direct fuel combustion, creating a clean environment.

However, because this is a calcination process, an adequate supply of oxygen (usually ambient air in an industrial furnace) is required to facilitate the conversion of solid carbon into gaseous carbon dioxide. Ensuring consistent airflow within the chamber is vital for complete purification.

Optimizing Your Post-Treatment Strategy

To achieve the highest quality B-doped SiC nanowires, align your furnace settings with your specific processing goals.

- If your primary focus is bulk purity: Strictly adhere to the 700 °C first-stage hold time to ensure the complete removal of robust graphite sheets before attempting surface cleaning.

- If your primary focus is surface activation: prioritize the stability of the 650 °C second stage to maximize the removal of free carbon without inducing thermal stress on the nanowire surface.

Success in this process ultimately relies on balancing aggressive impurity removal with the careful preservation of the nanostructure.

Summary Table:

| Purification Stage | Target Temperature | Primary Objective |

|---|---|---|

| Stage 1: Macro Impurities | 700 °C | Removal of graphite sheets and large particles |

| Stage 2: Surface Refinement | 650 °C | Elimination of residual free carbon for surface activation |

| Critical Requirement | Precision Control | Preventing oxidation of the SiC nanowire structure |

Elevate Your Nanomaterial Processing with KINTEK

Precision temperature control is non-negotiable for successful SiC nanowire purification. KINTEK provides industry-leading thermal solutions, including high-performance Muffle, Tube, and Vacuum furnaces, specifically designed to handle delicate two-stage calcination protocols.

Backed by expert R&D and manufacturing, our systems are fully customizable to meet the unique needs of your lab or industrial facility. Don't risk structural degradation—ensure complete impurity removal with KINTEK’s uniform heating technology.

Contact us today to find the perfect furnace for your application!

Visual Guide

References

- Tensile Strength and Electromagnetic Wave Absorption Properties of B-Doped SiC Nanowire/Silicone Composites. DOI: 10.3390/nano15171298

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How is a laboratory muffle furnace utilized during the debinding stage of HAp green bodies? Precision Thermal Control

- What are the benefits of front loading furnaces? Boost Efficiency and Safety in Your Lab

- How does a high-temperature box resistance furnace synthesize WC/C@N-S nanocatalysts? Precision Thermal Control

- What materials are used in the construction of the muffle furnace? Discover the Key Components for High-Temp Performance

- What is a muffle furnace and how does it generally function? Master Indirect Heating for Pure Results

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the main advantage of a muffle furnace? Ensure Purity and Longevity in High-Temp Processes

- What functions do muffle furnaces serve in the petrochemical industry? Essential Catalyst Prep and Quality Control