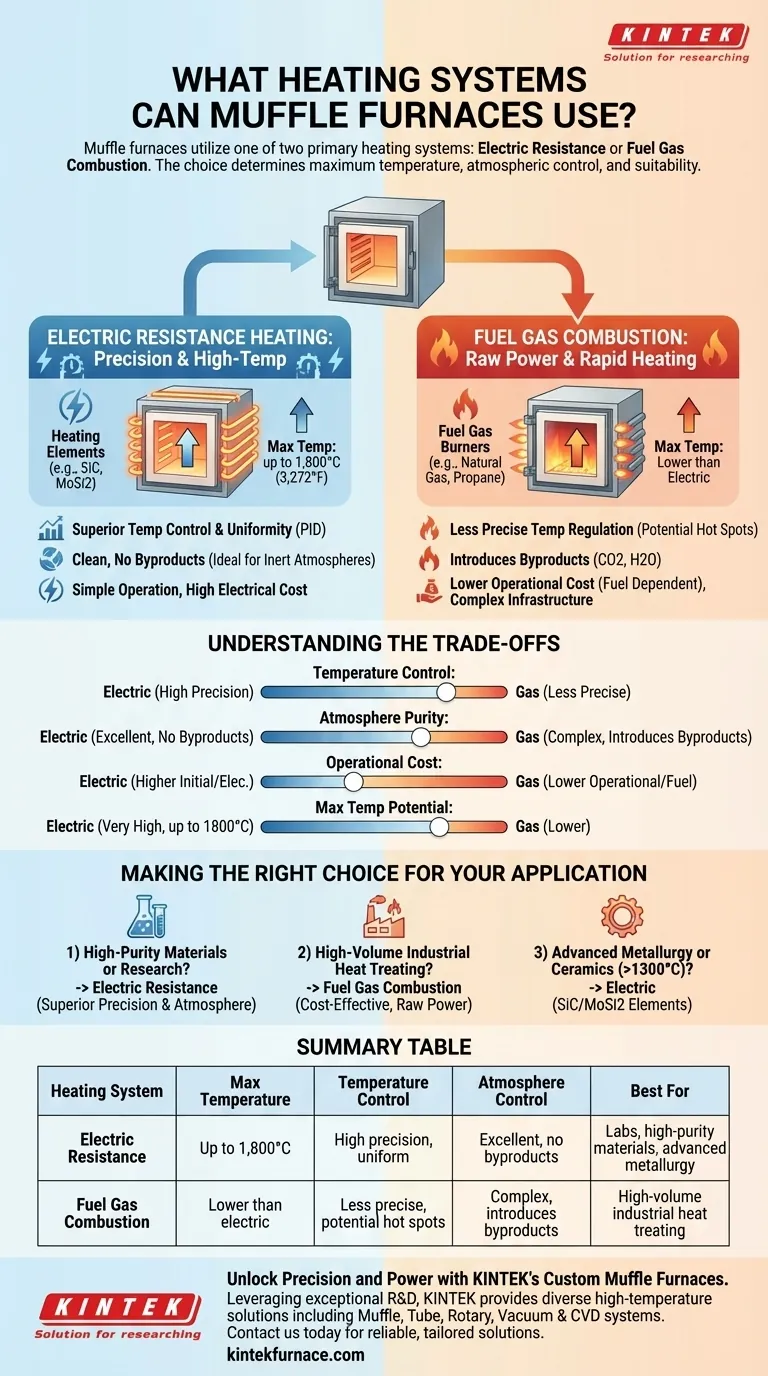

At their core, muffle furnaces utilize one of two primary heating systems: electric resistance heating or fuel gas combustion. The choice between these foundational technologies directly determines the furnace's maximum temperature, atmospheric control capabilities, and suitability for specific applications.

While both systems heat the furnace, the critical distinction lies in control versus power. Electric systems provide unparalleled precision and high-temperature potential, making them the standard for technical applications. Gas combustion offers raw, rapid heating power, often at a lower operational cost.

The Two Primary Heating Architectures

A muffle furnace's defining feature is the "muffle" itself—an isolated chamber that protects the workload from the direct heat source and combustion byproducts. The heating system works by heating the outside of this muffle, which then radiates heat inward.

Electric Resistance Heating: The Standard for Precision

This is the most common system for laboratory and high-tech industrial furnaces. It functions by passing a high electrical current through specialized heating elements.

These elements are made of materials with high electrical resistance, causing them to become extremely hot. The heat they generate radiates onto the muffle chamber.

Advances in materials for these elements, such as silicon carbide (SiC) and molybdenum disilicide (MoSi2), allow modern electric furnaces to reach working temperatures up to 1,800°C (3,272°F).

Fuel Gas Combustion: The Choice for Raw Power

In this design, fuel gas (like natural gas or propane) is burned in a chamber surrounding the muffle. This system is common in large-scale industrial settings.

The intense heat from the flames directly heats the exterior of the muffle, transferring thermal energy to the workload inside.

While powerful and capable of heating large chambers quickly, these systems offer less precise temperature regulation compared to their electric counterparts.

Understanding the Trade-offs

Choosing a heating system is not just about how it generates heat, but about the downstream implications for your process. The decision involves clear trade-offs between control, temperature, atmosphere, and cost.

Temperature Control and Uniformity

Electric furnaces offer superior temperature control. When paired with modern PID (Proportional-Integral-Derivative) controllers, they can maintain a setpoint with extreme accuracy and provide excellent temperature uniformity throughout the chamber.

Gas-fired furnaces are inherently more difficult to control with the same level of precision. The nature of combustion can lead to temperature fluctuations and potential hot spots on the muffle's surface.

Maximum Temperature and Atmosphere Control

Electric systems are capable of reaching higher maximum temperatures, enabling sophisticated applications in metallurgy, ceramics, and materials science. Crucially, they produce no combustion byproducts, making them ideal for processes requiring a controlled or inert atmosphere (e.g., nitrogen or argon).

Gas combustion introduces byproducts like carbon dioxide and water vapor into the furnace environment. While the muffle provides separation, maintaining a high-purity atmosphere is more complex and their maximum temperature is typically lower than specialized electric furnaces.

Operational Complexity and Cost

Electric furnaces are generally simpler to operate and automate. Their primary operational cost is electricity consumption, and while the initial investment for very high-temperature models can be high, they require less peripheral infrastructure.

Gas-fired furnaces often have a lower operational cost, contingent on local fuel prices. However, they require more complex infrastructure, including gas lines, ignition systems, exhaust flues, and more robust safety protocols.

Making the Right Choice for Your Application

Selecting the right heating system is the most critical decision when specifying a muffle furnace. Your choice should be guided entirely by the technical requirements of your work.

- If your primary focus is high-purity materials or scientific research: An electric resistance furnace is the correct choice for its superior temperature precision and atmosphere control.

- If your primary focus is high-volume industrial heat treating: A fuel gas combustion system may be more cost-effective and provide the necessary raw heating power for less sensitive processes.

- If your primary focus is advanced metallurgy or ceramics requiring over 1300°C: An electric furnace with specialized SiC or MoSi2 elements is the only technically viable option.

Understanding the fundamental heating mechanism is the first step toward selecting a furnace that truly serves your technical goals.

Summary Table:

| Heating System | Max Temperature | Temperature Control | Atmosphere Control | Best For |

|---|---|---|---|---|

| Electric Resistance | Up to 1,800°C | High precision, uniform | Excellent, no byproducts | Labs, high-purity materials, advanced metallurgy |

| Fuel Gas Combustion | Lower than electric | Less precise, potential hot spots | Complex, introduces byproducts | High-volume industrial heat treating |

Unlock Precision and Power with KINTEK's Custom Muffle Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need superior temperature control for research or cost-effective heating for industrial processes, we deliver reliable, tailored solutions that enhance efficiency and results.

Contact us today to discuss how our muffle furnaces can elevate your applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating