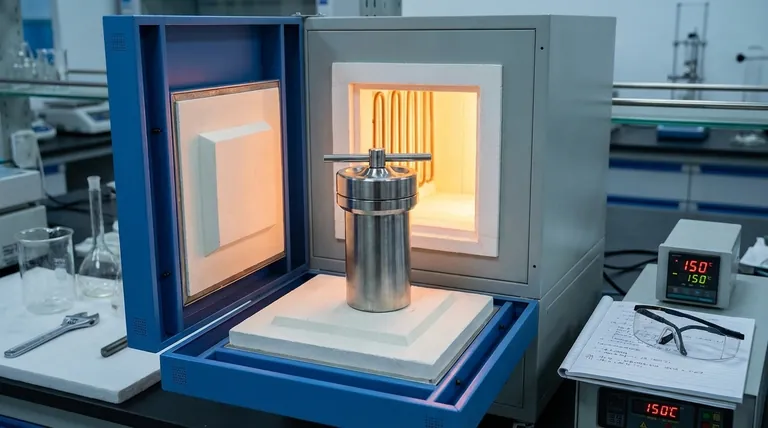

In hydrothermal synthesis, the laboratory box furnace functions as the critical external heating environment for the high-pressure autoclave containing your precursor solution. It envelops the sealed vessel in a consistent heat source, raising the internal temperature to specific set points (such as 150 °C) and maintaining that thermal energy for the duration of the reaction.

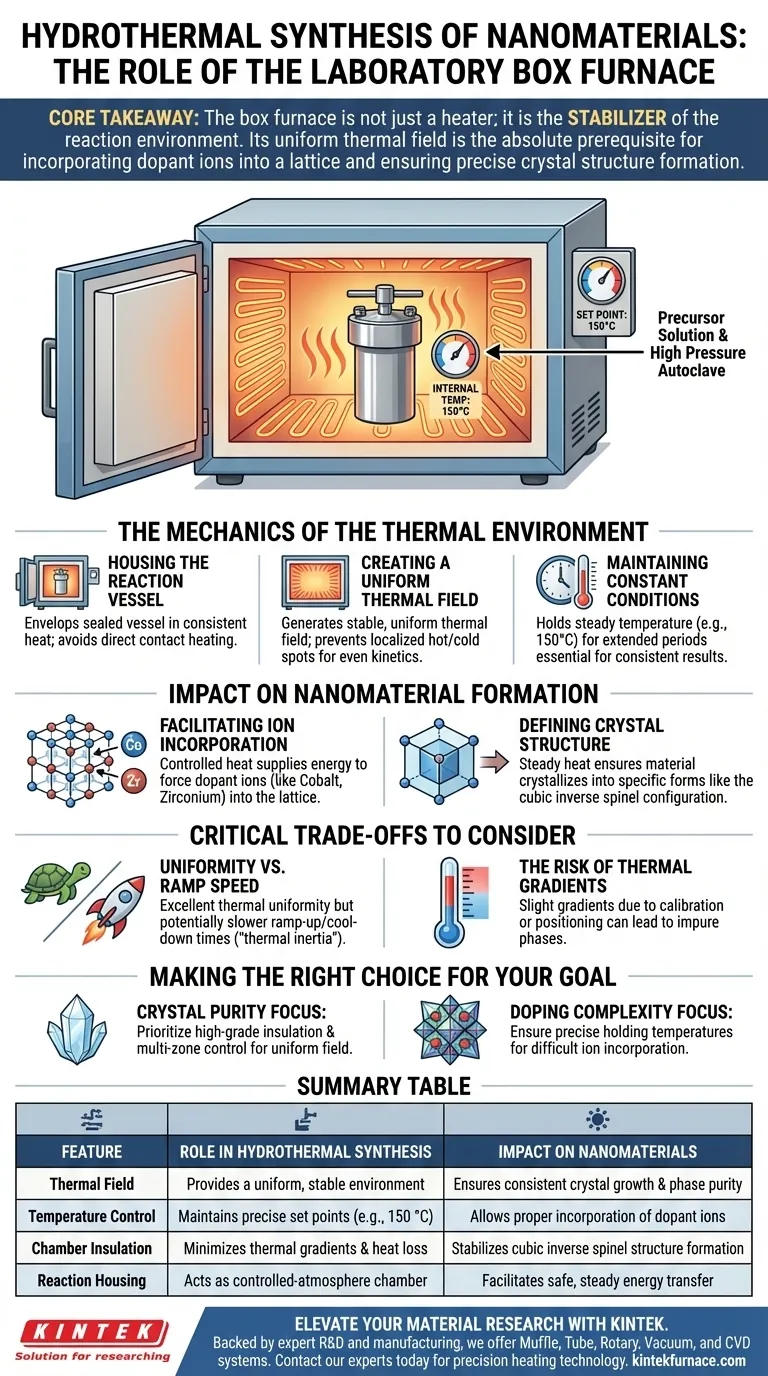

Core Takeaway The box furnace is not merely a heater; it is the stabilizer of the reaction environment. Its ability to provide a uniform thermal field is the absolute prerequisite for incorporating dopant ions into a lattice, ensuring the successful formation of precise crystal structures like the cubic inverse spinel configuration.

The Mechanics of the Thermal Environment

Housing the Reaction Vessel

The box furnace acts as a chamber to house the autoclave. Unlike direct heating methods (like a hot plate), the box furnace surrounds the entire vessel with heated air.

Creating a Uniform Thermal Field

The primary function of the furnace is to generate a stable and uniform thermal field. This ensures that heat is distributed evenly across the surface of the autoclave, preventing localized hot or cold spots that could skew the reaction kinetics.

Maintaining Constant Conditions

For synthesis to occur, the system must hold a steady temperature, specifically 150 °C in common ferrite synthesis protocols. The furnace's insulation and control systems maintain this plateau, which is essential for consistent chemical results.

Impact on Nanomaterial Formation

Facilitating Ion Incorporation

The controlled heat provided by the furnace supplies the energy required to force dopant ions into the material's structure. For example, this thermal environment allows Cobalt (Co) and Zirconium (Zr) ions to successfully integrate into an Iron Oxide lattice.

Defining Crystal Structure

The stability of the heating process dictates the final morphology of the nanomaterial. A fluctuating temperature would yield inconsistent results, but the steady heat of the box furnace ensures the material crystallizes into a specific cubic structure with an inverse spinel configuration.

Critical Trade-offs to Consider

Uniformity vs. Ramp Speed

While box furnaces offer excellent thermal uniformity, they may have slower ramp-up and cool-down times compared to other heating methods. This "thermal inertia" is beneficial for stability but requires patience during the production cycle.

The Risk of Thermal Gradients

If the box furnace is not calibrated or if the autoclave is positioned poorly, slight thermal gradients can occur. Even minor deviations can prevent the proper incorporation of ions, leading to impure phases rather than the desired inverse spinel structure.

Making the Right Choice for Your Goal

To maximize the effectiveness of a box furnace in hydrothermal synthesis, consider your specific objective:

- If your primary focus is Crystal Purity: Prioritize a furnace with high-grade insulation and multi-zone control to ensure the thermal field remains absolutely uniform for ion incorporation.

- If your primary focus is Doping Complexity: Ensure your furnace can maintain precise holding temperatures (e.g., exactly 150 °C) for extended periods to force difficult ions like Cobalt or Zirconium into the lattice.

The quality of your external thermal field directly dictates the internal structural integrity of your nanomaterial.

Summary Table:

| Feature | Role in Hydrothermal Synthesis | Impact on Nanomaterials |

|---|---|---|

| Thermal Field | Provides a uniform, stable environment around the autoclave | Ensures consistent crystal growth and phase purity |

| Temperature Control | Maintains precise set points (e.g., 150 °C) | Allows proper incorporation of dopant ions (Co, Zr) |

| Chamber Insulation | Minimizes thermal gradients and heat loss | Stabilizes cubic inverse spinel structure formation |

| Reaction Housing | Acts as a controlled-atmosphere heating chamber | Facilitates safe and steady energy transfer to vessels |

Elevate Your Material Research with KINTEK

Precise crystal engineering requires an unwavering thermal environment. KINTEK provides high-performance laboratory solutions specifically designed for the rigorous demands of nanomaterial production. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique hydrothermal synthesis needs.

Whether you are doping complex ions or targeting specific cubic morphologies, our high-temperature furnaces ensure the thermal stability your lab requires. Contact our technical experts today to discover how KINTEK’s precision heating technology can improve your research outcomes.

Visual Guide

References

- Saba Yaqoob, Alberto D’Amore. Magnetic and Dielectric Properties of Cobalt and Zirconium Co-Doped Iron Oxide Nanoparticles via the Hydrothermal Synthesis Approach. DOI: 10.3390/jcs9010032

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does an industrial electric box furnace maintain sample alignment? Ensure Precision in High-Throughput Calcination

- What are the main applications of a muffle furnace? Unlock Precision Heating for Material Transformations

- What are the key specifications of a typical muffle furnace? Essential Guide for Lab Efficiency

- What are the benefits of using a muffle furnace? Achieve Precise, Contamination-Free Heating for Your Lab

- What is a muffle furnace and what are its primary uses? Unlock Precise High-Temp Solutions

- What is the role of a muffle furnace in the preparation of bulk graphitic carbon nitride (BCN)? Master BCN Synthesis

- What is the critical role of a laboratory high-temperature muffle furnace in TiO2/LDH? Unlock Superior Crystallization

- What is the primary function of an electric muffle furnace? Ensure Purity and Uniform Heating