At its core, a muffle furnace offers significant benefits by providing an extremely precise, uniform, and contamination-free heating environment. Its key advantages stem from an isolated chamber that protects samples from direct heat and combustion byproducts, enabling high-purity thermal processing for a wide range of scientific and industrial applications.

The primary value of a muffle furnace is not simply its ability to reach high temperatures. Its true advantage lies in creating a highly controlled and isolated environment, ensuring that the material you are processing is affected only by heat, not by contaminants from the heating source itself.

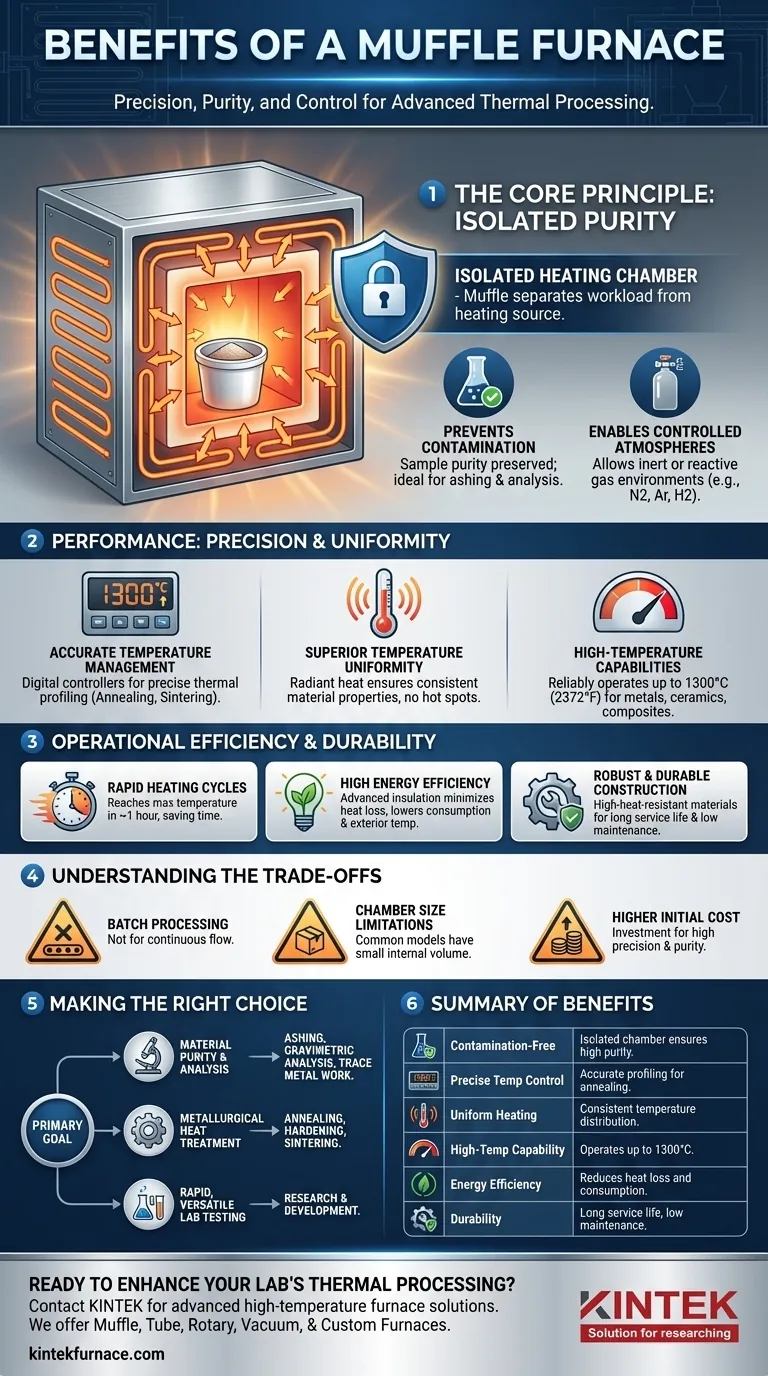

The Core Principle: Why "Muffle" Means Purity

The defining feature of a muffle furnace is the muffle—an isolated inner chamber that separates the workload from the heating elements. This design is the source of its most critical benefits.

An Isolated Heating Chamber

The muffle is a box-like enclosure, typically made of high-temperature ceramic or alloy. Heating elements are positioned outside this chamber, heating the muffle, which then radiates heat uniformly to the sample inside.

Preventing Sample Contamination

Because the sample never comes into contact with the heating elements or any byproducts of combustion (in fuel-fired models), its chemical purity is preserved. This is indispensable for applications like ashing, trace element analysis, or creating high-purity materials where contamination would invalidate results.

Enabling Controlled Atmospheres

This separation also allows for precise atmospheric control. The chamber can be purged and filled with inert gases like nitrogen or argon, or reactive gases like hydrogen. This is impossible in furnaces where the sample is exposed to the combustion source.

Performance: Precision and Uniformity

Beyond purity, a muffle furnace delivers exceptional control over the heating process, which is critical for achieving repeatable and reliable results.

Accurate Temperature Management

Modern muffle furnaces are equipped with sophisticated digital controllers and thermocouples that allow for precise temperature programming. This ensures the material is subjected to the exact thermal profile required for processes like annealing, sintering, or tempering.

Superior Temperature Uniformity

The design, where heat radiates from the chamber walls, promotes excellent temperature uniformity. Every part of the sample receives the same amount of heat, preventing hot spots and ensuring consistent material properties throughout the entire batch.

High-Temperature Capabilities

Muffle furnaces are engineered to operate reliably at very high temperatures, with many models reaching between 1100°C and 1300°C (2012°F to 2372°F). This makes them suitable for processing ceramics, metals, and advanced composite materials.

Operational Efficiency and Durability

A well-designed muffle furnace is an investment built for efficiency and a long operational lifespan.

Rapid Heating Cycles

Thanks to advanced insulation materials and powerful heating elements, many lab-scale furnaces can reach their maximum temperature in about an hour. This rapid heating capability saves valuable time in research and production environments.

High Energy Efficiency

Heavy-duty thermal insulation minimizes heat loss to the surrounding environment. This not only makes the furnace safer by keeping the exterior cool but also reduces energy consumption compared to less insulated heating methods.

Robust and Durable Construction

These furnaces are constructed from high-heat-resistant materials and are designed for a long service life with low maintenance requirements. This durability makes them a cost-effective solution over the long term.

Understanding the Trade-offs

While highly beneficial, muffle furnaces are not the right tool for every heating task. It's important to understand their limitations.

Batch Processing Nature

Muffle furnaces are designed for processing materials in batches. They are not suited for continuous-flow industrial processes where materials move along a conveyor.

Chamber Size Limitations

While large industrial models exist, the most common laboratory muffle furnaces have a relatively small internal volume. This limits the size and quantity of samples that can be processed at one time.

Higher Initial Cost

Compared to a simple laboratory oven, a muffle furnace represents a higher initial investment. This cost is justified by its high-temperature capability, precision, and contamination control, but it may be overkill for simple drying or warming applications.

Making the Right Choice for Your Application

Selecting the right heating equipment depends entirely on your primary goal.

- If your primary focus is material purity and analysis: The isolated chamber is the most critical benefit, making a muffle furnace the ideal choice for ashing, gravimetric analysis, or trace metal work.

- If your primary focus is metallurgical heat treatment: The combination of precise temperature control and excellent uniformity is essential for achieving desired material properties in processes like annealing, hardening, or sintering.

- If your primary focus is rapid, versatile lab testing: The fast heat-up times and ability to handle diverse materials at high temperatures make it an indispensable tool for research and development.

Ultimately, choosing a muffle furnace is a decision to prioritize control, purity, and precision in your thermal processing.

Summary Table:

| Benefit | Description |

|---|---|

| Contamination-Free Heating | Isolated chamber prevents sample contact with heating elements, ensuring high purity for ashing and analysis. |

| Precise Temperature Control | Digital controllers and thermocouples allow accurate thermal profiling for annealing and sintering. |

| Uniform Heating | Radiant heat from chamber walls ensures consistent temperature distribution, eliminating hot spots. |

| High-Temperature Capability | Operates reliably up to 1300°C, ideal for ceramics, metals, and composites. |

| Energy Efficiency | Advanced insulation reduces heat loss, lowering energy consumption and improving safety. |

| Durability | Robust construction with high-heat-resistant materials ensures long service life and low maintenance. |

Ready to enhance your lab's thermal processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our furnaces can deliver superior performance and reliability for your applications!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals