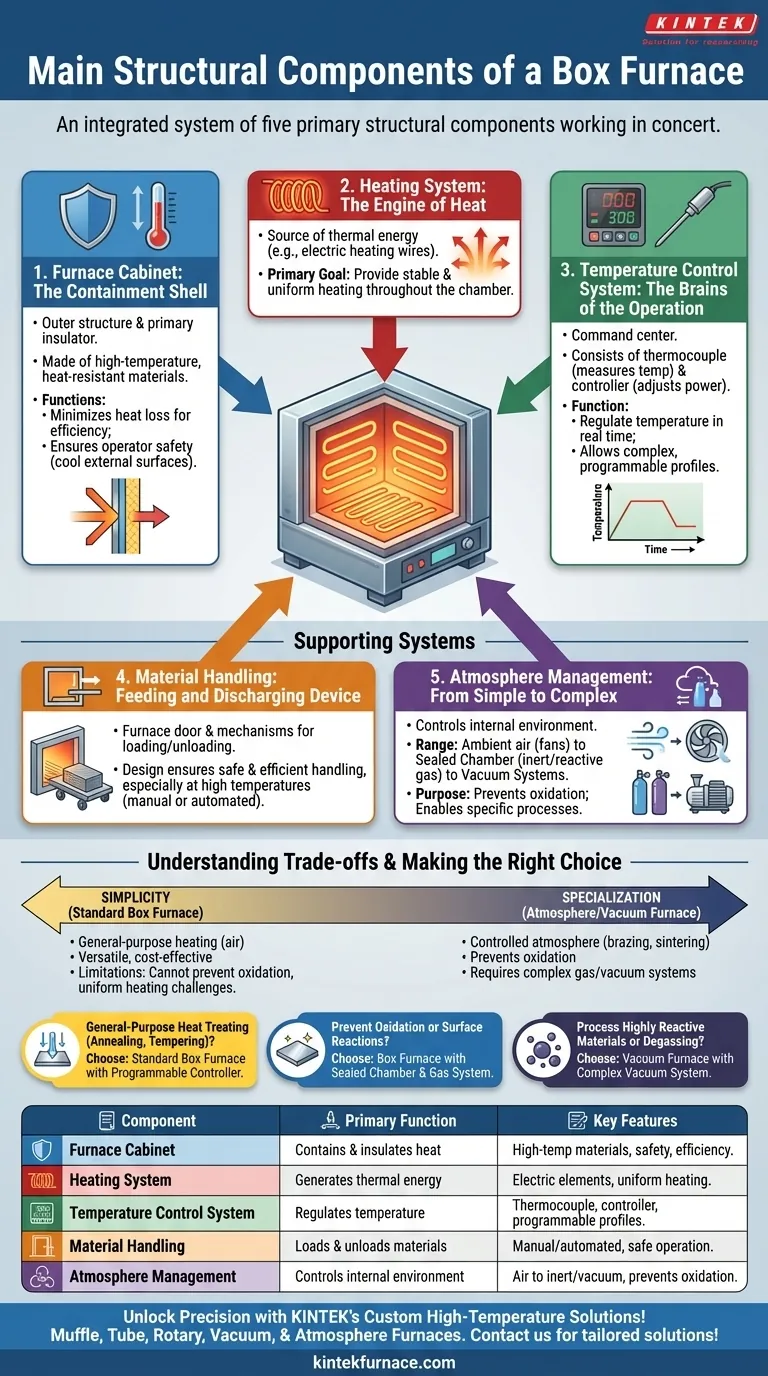

At its core, a box furnace is a system of five primary structural components working in concert. These are the furnace cabinet (or body), the heating elements, the temperature control system, a method for loading and unloading materials, and any auxiliary equipment designed to modify the internal environment.

A box furnace is best understood not as a list of parts, but as an integrated system. Each component—from the insulating cabinet to the precise control system—plays a critical role in creating a stable, controlled high-temperature environment for material processing.

The Core Components of a Box Furnace

The fundamental design of a box furnace revolves around three key components that generate, contain, and regulate heat. Understanding their function is the first step to understanding the entire system.

The Furnace Cabinet: The Containment Shell

The cabinet is the outer structure and primary insulator of the furnace. It is built from high-temperature, heat-resistant materials to serve two main purposes.

First, it minimizes heat loss, ensuring energy efficiency and the ability to reach and maintain high temperatures. Second, and more importantly, it ensures operator safety by keeping the external surfaces at a safe temperature.

The Heating System: The Engine of Heat

Inside the cabinet are the heating elements, which are the source of thermal energy. These are most commonly made of electric heating wire or similar resistance-based materials.

The primary goal of the heating system is to provide stable and uniform heating throughout the furnace chamber, ensuring the entire workpiece is processed at the same temperature.

The Temperature Control System: The Brains of the Operation

This system is the command center of the furnace. It consists of a thermocouple to measure the internal temperature and a controller that adjusts power to the heating elements.

Its function is to regulate the furnace temperature in real time, following a specific setpoint or a programmed heating and cooling profile. Advanced systems allow for complex, multi-step thermal cycles.

Supporting Systems for Process Control

Beyond the core components, supporting systems enable the practical use of the furnace for specific applications, from simply getting material in and out to controlling the chemical environment inside.

Material Handling: The Feeding and Discharging Device

This refers to the furnace door and any mechanisms for loading and unloading the workload. The design must ensure safe and efficient material handling, especially when dealing with high temperatures.

In simple furnaces, this is a manual door. In more advanced or automated systems, it can involve powered doors, carts, or other mechanisms.

Atmosphere Management: From Simple to Complex

This is where box furnaces show their greatest variation. All furnaces have some form of atmosphere control, even if it's just air.

A basic box furnace operates in ambient air and may use auxiliary equipment like fans to improve heat circulation.

More specialized atmosphere furnaces include a sealed chamber and a gas supply system to create an inert or reactive environment, preventing oxidation. Vacuum furnaces represent the most complex form, incorporating a robust vacuum system with pumps and valves to remove nearly all atmosphere.

Understanding the Trade-offs

No single furnace design is perfect for every task. The components and complexity of a box furnace are directly tied to its intended purpose, creating a series of trade-offs.

Simplicity vs. Specialization

A standard box furnace is a versatile, general-purpose tool for heating materials in air. However, this simplicity means it cannot perform processes that require a controlled atmosphere, such as brazing or sintering of reactive metals. For those, a more complex and expensive atmosphere or vacuum furnace is necessary.

Uniformity and Physical Limitations

While heating elements are designed for uniformity, "hot spots" or temperature gradients can still occur, especially in larger furnaces or with densely packed loads. Achieving true temperature uniformity often requires multiple heating zones and sophisticated control systems.

Process Integrity and Contamination

In a standard box furnace, the workpiece is exposed to air, which will cause oxidation on the surface of most metals at high temperatures. If surface finish or chemical purity is critical, the lack of atmosphere control is a significant limitation.

Making the Right Choice for Your Goal

Selecting the right furnace means matching its components and capabilities to your specific processing needs.

- If your primary focus is general-purpose heat treating (annealing, tempering): A standard box furnace with a reliable, programmable temperature controller is the correct and most cost-effective tool.

- If your primary focus is preventing oxidation or surface reactions: You must use an atmosphere box furnace equipped with a sealed chamber and a gas delivery system.

- If your primary focus is processing highly reactive materials or degassing: A vacuum furnace, with its complex vacuum and cooling systems, is the only viable option.

Ultimately, understanding the function of each component empowers you to select the right tool for your specific thermal processing task.

Summary Table:

| Component | Primary Function | Key Features |

|---|---|---|

| Furnace Cabinet | Contains and insulates heat | High-temperature materials, ensures safety and efficiency |

| Heating System | Generates thermal energy | Electric heating elements, provides uniform heating |

| Temperature Control System | Regulates temperature | Thermocouple and controller, allows programmable profiles |

| Material Handling | Loads and unloads materials | Manual or automated doors, ensures safe operation |

| Atmosphere Management | Controls internal environment | From air to inert/vacuum systems, prevents oxidation |

Unlock Precision in Your Lab with KINTEK's Custom High-Temperature Solutions! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior heat treatment and process control. Contact us today to discuss how our tailored solutions can enhance your material processing efficiency and results!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What functions does a high-temperature muffle furnace perform during cathode precursor processing?

- What is the core function of a muffle furnace in mesoporous silica prep? Master Template Removal & Calcination

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?

- What is the core function of a high-temperature muffle furnace in silver nanoparticle circuits? Optimize Conductivity

- What role does a laboratory muffle furnace play in high-purity alpha-alumina prep? Master Calcination and Phase Shifts