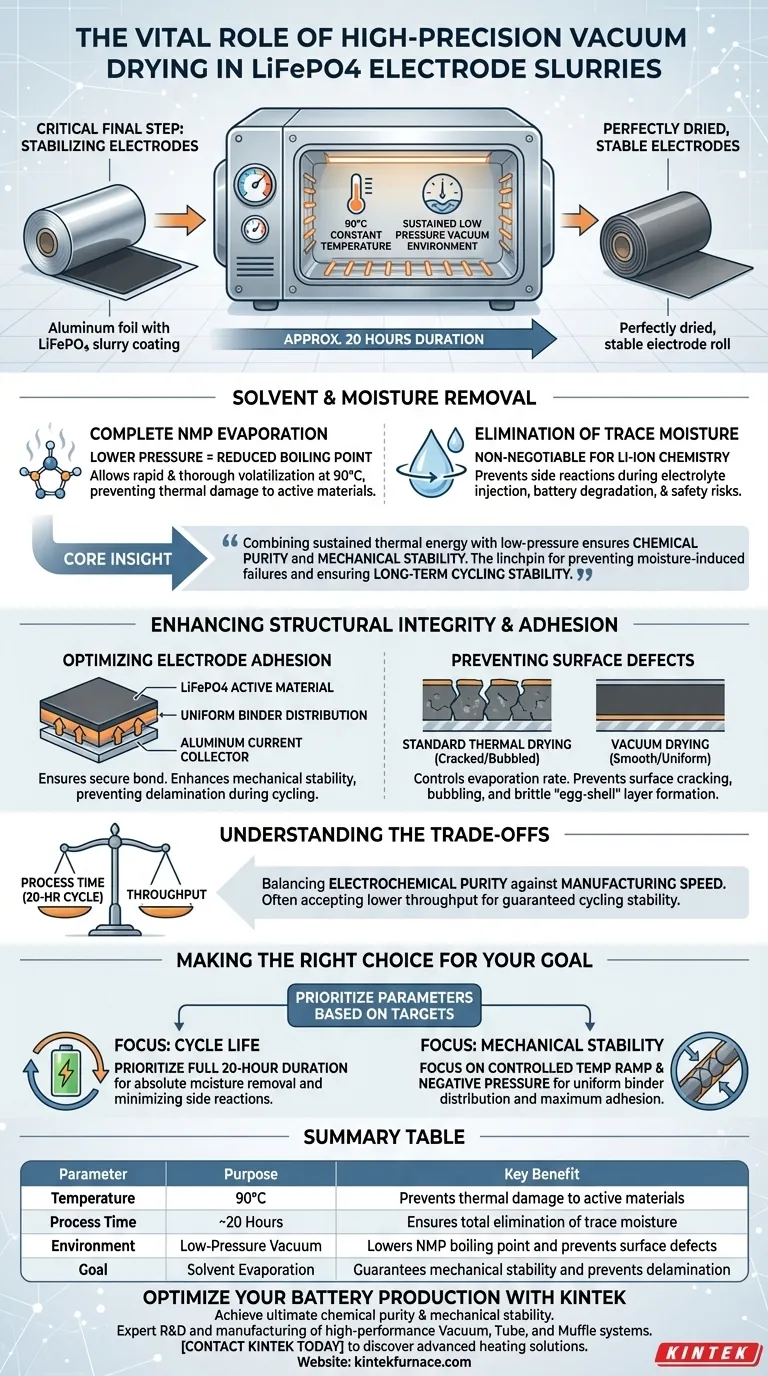

High-precision vacuum drying is the critical final step in stabilizing LiFePO4 electrode slurries prior to cell assembly. It involves treating the coated aluminum foil at controlled temperatures, specifically 90°C for approximately 20 hours, to guarantee the total evaporation of N-methyl-2-pyrrolidone (NMP) solvents and the elimination of residual trace moisture.

Core Insight: By combining sustained thermal energy with a low-pressure environment, vacuum drying ensures the chemical purity and mechanical stability of the electrode. This process is the linchpin for preventing moisture-induced failure mechanisms and ensuring the long-term cycling stability of the battery.

The Critical Role of Solvent and Moisture Removal

Complete Evaporation of NMP

The primary function of the vacuum oven is to drive off N-methyl-2-pyrrolidone (NMP), the organic solvent used to create the slurry.

By lowering the pressure, the oven reduces the boiling point of the solvent. This allows for rapid and thorough volatilization at moderate temperatures (90°C), preventing the slurry from remaining "wet" without subjecting the active materials to damaging levels of heat.

Elimination of Trace Moisture

Beyond bulk solvent removal, the process targets residual trace moisture deep within the electrode structure.

Removing this moisture is non-negotiable for lithium-ion chemistry. If water remains, it can trigger side reactions during electrolyte injection, leading to battery degradation and safety risks.

Enhancing Structural Integrity and Adhesion

Optimizing Electrode Adhesion

A thoroughly dried electrode is required to secure the bond between the active LiFePO4 material and the aluminum current collector.

The vacuum drying process ensures that the binder distributes uniformly. This enhances the mechanical stability of the electrode, preventing delamination or detachment during the physical stress of battery cycling.

Preventing Surface Defects

Vacuum drying helps manage the evaporation rate to avoid defects common in standard thermal drying.

By lowering the boiling point, the solvent evaporates evenly rather than "flashing" off the surface. This prevents the surface layer from drying too quickly, which effectively mitigates cracking, bubbling, or the formation of a brittle "egg-shell" layer on the coating surface.

Understanding the Trade-offs

Process Time vs. Throughput

While high-precision vacuum drying offers superior quality, it is inherently a time-intensive process.

The requirement for a 20-hour cycle significantly impacts production throughput compared to rapid convective drying methods. Engineers must balance the need for electrochemical purity against manufacturing speed, often accepting lower throughput to guarantee the cycling stability of the final cell.

Making the Right Choice for Your Goal

When integrating vacuum drying into your electrode production line, prioritize parameters based on your specific performance targets:

- If your primary focus is Cycle Life: Prioritize the full 20-hour duration to ensure absolute moisture removal, minimizing side reactions over time.

- If your primary focus is Mechanical Stability: Focus on the controlled temperature ramp and negative pressure levels to ensure uniform binder distribution and maximum adhesion to the current collector.

Precision in this stage is not merely about drying; it is about establishing the fundamental baseline for battery reliability.

Summary Table:

| Parameter | Purpose | Key Benefit |

|---|---|---|

| Temperature | 90°C | Prevents thermal damage to active materials |

| Process Time | ~20 Hours | Ensures total elimination of trace moisture |

| Environment | Low-Pressure Vacuum | Lowers NMP boiling point and prevents surface defects |

| Goal | Solvent Evaporation | Guarantees mechanical stability and prevents delamination |

Optimize Your Battery Production with KINTEK

Achieve the ultimate chemical purity and mechanical stability for your LiFePO4 electrodes. At KINTEK, we understand that precision drying is the linchpin of battery reliability. Backed by expert R&D and manufacturing, we offer high-performance Vacuum, Tube, and Muffle systems specifically designed to handle the rigorous 20-hour cycles required for solvent and moisture removal.

Whether you need customizable lab-scale high-temp furnaces or industrial-grade drying solutions, our systems are engineered to prevent surface defects and ensure uniform binder distribution. Contact KINTEK today to discover how our advanced heating solutions can enhance your electrochemical performance and battery cycling stability.

Visual Guide

References

- Da Eun Kim, Yong Joon Park. Improving the Electrochemical Properties of LiFePO4 by Mixed-source-derived Carbon Layer. DOI: 10.33961/jecst.2025.00213

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the typical vacuum levels for medium, high, and ultra-high vacuum furnaces? Optimize Your Process Efficiency

- What is the basic structure of a vacuum furnace? Discover Its Core Components and Functions

- How is a vacuum created inside the furnace chamber? Master the Process for Contamination-Free Results

- What are the disadvantages of using a vacuum furnace? High Costs, Material Limits, and More

- How do customized vacuum furnaces improve product quality? Achieve Superior Heat Treatment for Your Materials

- What industries utilize vacuum technology in thermal processing? Unlock High-Performance Material Production

- What furnace technology is needed for higher temperature sintering? Choose Vacuum or Walking Beam for Optimal Results

- Why is degassing important in metal melting, and how does a vacuum help? Achieve Purer, Stronger Metal Alloys