Creating a vacuum within a furnace chamber is a foundational process in modern material science and manufacturing. It is achieved by first creating a hermetically sealed environment and then using a powerful vacuum pump to physically evacuate the air and other atmospheric gases. This removal of reactive elements like oxygen prevents unwanted chemical reactions, such as oxidation, at the high temperatures required for processes like brazing, sintering, or heat treating.

The creation of a vacuum is not merely about removing air; it is an engineering discipline focused on building a completely isolated and controllable system. The effectiveness of the vacuum depends equally on the pump's power, the integrity of the chamber's seals, and the durability of its construction.

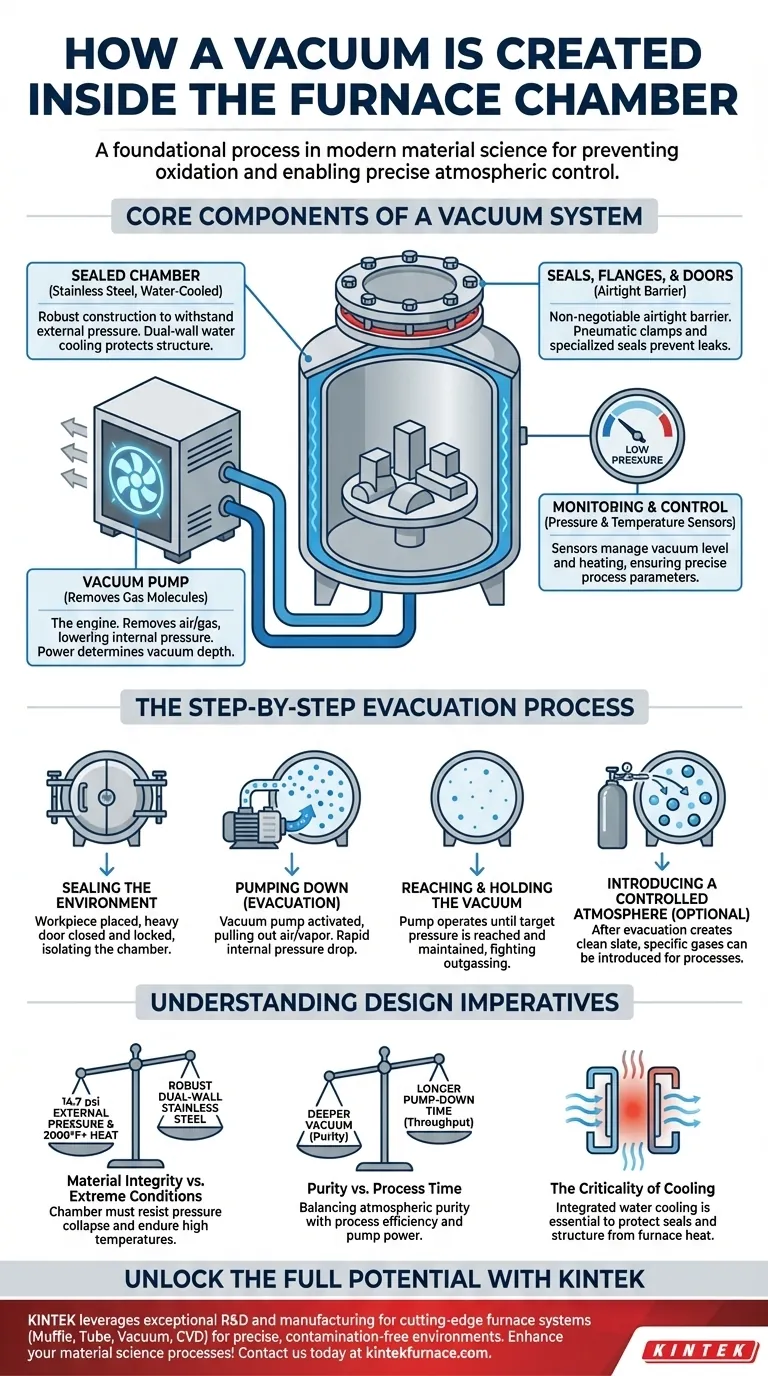

The Core Components of a Vacuum System

A vacuum furnace is more than just a hot box; it is a precisely engineered system where each component plays a critical role in creating and maintaining a sub-atmospheric environment.

The Sealed Chamber

The chamber is the primary containment vessel. It is typically constructed from robust materials like stainless steel to withstand the immense external atmospheric pressure that pushes on it when a vacuum is drawn inside.

Many chambers feature a dual-wall, water-cooled design. This continuous water jacketing prevents the structure and its critical seals from overheating, ensuring they remain intact and effective throughout the high-temperature process.

The Vacuum Pump

This is the engine of the vacuum system. Once the chamber is sealed, the vacuum pump is activated to remove gas molecules, lowering the internal pressure. The type and power of the pump determine how low the pressure can go (the "depth" of the vacuum) and how quickly it can be achieved.

Seals, Flanges, and Doors

An airtight seal is non-negotiable. Furnace doors are equipped with heavy-duty pneumatic clamps and specialized seals to create a perfect barrier against the outside atmosphere. All entry points, such as power feed-throughs or gas inlets, are sealed with high-integrity flanges to prevent even microscopic leaks.

Monitoring and Control Systems

The environment inside the chamber is managed by a suite of sensors. Pressure gauges monitor the vacuum level, while a temperature control system manages the heating elements. This allows operators to ensure the process parameters are met precisely.

The Step-by-Step Evacuation Process

Creating the vacuum follows a clear, logical sequence designed for safety and process integrity.

1. Sealing the Environment

First, the workpiece or material is placed inside the furnace. The heavy, often water-cooled, door is closed and locked using multiple clamps. At this point, the chamber is an isolated system, ready for evacuation.

2. Pumping Down (Evacuation)

With the chamber sealed, the vacuum pump is turned on. It begins to pull air and water vapor out of the chamber, causing the internal pressure to drop rapidly. This is the most critical phase for removing the oxygen that could contaminate the process.

3. Reaching and Holding the Vacuum

The pump continues to operate until the desired pressure level, specified by the experiment or manufacturing process, is reached. A well-designed system will maintain this low pressure, fighting off any residual outgassing from the workpiece or chamber walls.

4. Introducing a Controlled Atmosphere (Optional)

For many processes, creating a vacuum is just the first step. After evacuation creates a clean, inert slate, a specific gas can be introduced. For example, hydrocarbons like propane might be added for carburizing, or an inert gas like argon may be used to provide a stable, non-reactive environment during heating.

Understanding the Trade-offs and Design Imperatives

The design of a vacuum furnace is a balance of competing physical demands, where every choice has a consequence.

Material Integrity vs. Extreme Conditions

The chamber walls must be strong enough to resist collapsing under up to 14.7 psi (1 atm) of external pressure while simultaneously enduring internal temperatures that can exceed 2000°F (1100°C). This is why cooled, dual-wall stainless steel construction is the industry standard.

Purity vs. Process Time

Achieving a "harder" (deeper) vacuum requires more powerful pumps and a longer pump-down time. A process must balance the need for atmospheric purity against the economic need for throughput. A leak-tight system is critical, as even a small leak can prevent the furnace from reaching the target vacuum level.

The Criticality of Cooling

Without an integrated cooling system, the heat from the furnace would quickly destroy the door seals and compromise the chamber's structural integrity. Water cooling on the chamber body, door, and power feed-throughs is essential for protecting the vacuum seals and ensuring repeatable, reliable performance.

Making the Right Choice for Your Goal

The design and operation of a vacuum furnace system are dictated by the specific outcome you need to achieve.

- If your primary focus is preventing oxidation and contamination: Your priority is the integrity of the seal and the ability of the pump to remove virtually all oxygen before heating begins.

- If your primary focus is introducing a specific process gas (like in carburizing): Your goal is to first create a clean slate with a deep vacuum, then precisely control the introduction and pressure of the desired gas.

- If your primary focus is high-temperature structural integrity: You must ensure the chamber is built with robust, water-cooled materials like dual-wall stainless steel to withstand both thermal stress and external atmospheric pressure.

Ultimately, creating a vacuum is the foundational step that enables precise atmospheric control, which is the true purpose of a vacuum furnace.

Summary Table:

| Component | Role in Vacuum Creation |

|---|---|

| Sealed Chamber | Provides airtight containment, often made of stainless steel with water cooling to resist pressure and heat. |

| Vacuum Pump | Removes air and gases to lower pressure, determining vacuum depth and speed. |

| Seals and Flanges | Ensure no leaks with heavy-duty clamps and specialized seals for isolation. |

| Monitoring Systems | Use sensors to track pressure and temperature for precise control. |

| Step-by-Step Process | Involves sealing, pumping down, holding vacuum, and optionally adding gases for specific treatments. |

Unlock the Full Potential of Your Laboratory with KINTEK's Advanced Vacuum Furnace Solutions

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge high-temperature furnace systems. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed to deliver precise, contamination-free environments for applications like brazing, sintering, and heat treating. With our strong deep customization capability, we tailor solutions to meet your unique experimental requirements, ensuring optimal performance and reliability.

Ready to enhance your material science processes? Contact us today to discuss how our vacuum furnaces can drive your success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today