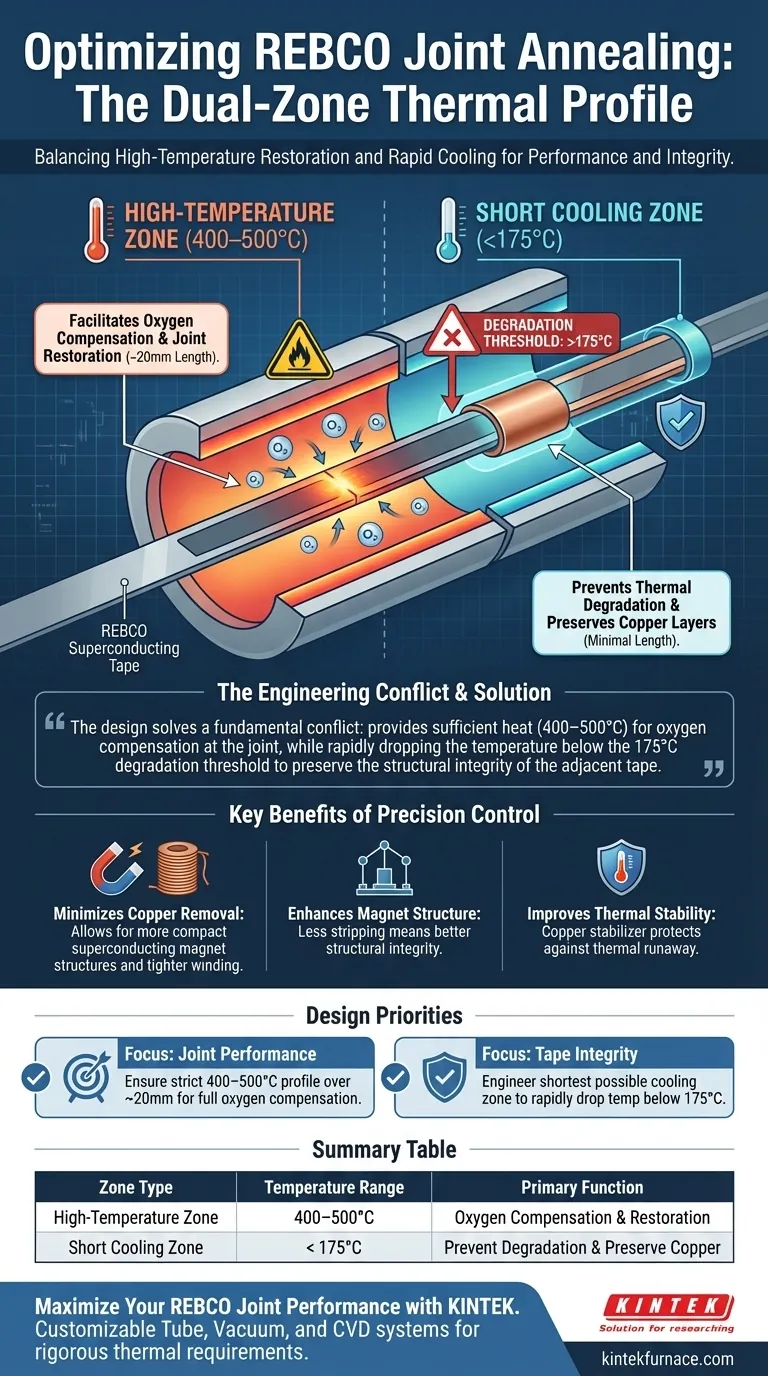

The thermal profile of a tube annealing furnace is the single most critical factor in successful REBCO joint fabrication. To create a viable joint, the furnace must maintain a high-temperature zone to restore superconducting properties while simultaneously employing a short cooling zone to prevent material damage. This precise configuration balances the chemical requirements of the joint against the thermal fragility of the surrounding tape.

The design solves a fundamental engineering conflict: it provides sufficient heat (400–500°C) for oxygen compensation at the joint, while rapidly dropping the temperature below the 175°C degradation threshold to preserve the structural integrity of the adjacent tape.

The Role of the High-Temperature Zone

Ensuring Oxygen Compensation

The primary function of the high-temperature zone is to facilitate oxygen compensation within the joint area. Without this specific thermal treatment, the superconducting properties of the joint cannot be fully realized or restored.

The Specific Thermal Window

To achieve this, the furnace must maintain a temperature range between 400 and 500 degrees Celsius. The heated zone is typically designed to be approximately 20mm in length, concentrating the thermal energy exactly where the joint formation occurs.

The Criticality of a Short Cooling Zone

The 175°C Degradation Threshold

REBCO tapes have a specific thermal limit. Exposure to temperatures above 175 degrees Celsius can cause significant degradation to the tape's performance.

Reducing Exposure Time

A very short cooling zone is essential to minimize the physical length of the tape that remains above this critical 175°C threshold. If the cooling zone were long, the temperature gradient would be too gradual, keeping a larger section of the tape in the "danger zone" for an extended period.

Engineering Implications and Trade-offs

Minimizing Copper Removal

The efficiency of the cooling zone directly impacts how the tape is prepared. By strictly limiting thermal degradation, you minimize the amount of the copper stabilization layer that must be removed.

Enhancing Magnet Structure

Preserving the copper layer allows for a more compact superconducting magnet structure. Less stripping means better structural integrity and tighter winding capabilities.

Improving Thermal Stability

Optimizing the furnace design to retain the copper layer results in enhanced thermal stability for the joints. The copper acts as a stabilizer, protecting the joint against thermal runaway during operation.

Making the Right Choice for Your Goal

To maximize the performance of your REBCO joints, consider these design priorities:

- If your primary focus is Joint Performance: Ensure your high-temperature zone maintains a strict 400–500°C profile over a 20mm span to guarantee full oxygen compensation.

- If your primary focus is Tape Integrity: Engineer the cooling zone to be as short as possible to rapidly drop the material temperature below the 175°C degradation threshold.

By controlling these two zones, you transform the annealing process from a liability into a precision tool for building compact, stable high-field magnets.

Summary Table:

| Zone Type | Temperature Range | Length (Approx.) | Primary Function |

|---|---|---|---|

| High-Temperature Zone | 400–500°C | 20mm | Facilitates oxygen compensation and joint restoration |

| Short Cooling Zone | < 175°C | Minimal | Prevents thermal degradation and preserves copper layers |

Maximize Your REBCO Joint Performance with KINTEK

Precise thermal profiling is the difference between a successful superconducting joint and permanent material degradation. Backed by expert R&D and manufacturing, KINTEK offers specialized Tube, Vacuum, and CVD systems designed to handle the rigorous 400–500°C requirements and rapid cooling gradients essential for high-field magnet fabrication.

Our lab high-temp furnaces are fully customizable to meet your unique length, temperature, and atmospheric needs, ensuring your copper stabilization layers remain intact for a more compact magnet structure.

Ready to optimize your annealing process? Contact our engineering team today to discuss your custom furnace requirements and enhance your lab's research capabilities.

Visual Guide

References

- Zili Zhang, Qiuliang Wang. A Tube Furnace Design for the Oxygen Annealing of a REBCO Superconducting Joint. DOI: 10.3390/ma18133053

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of introducing high-purity nitrogen into a tube furnace? Enhance Biomass Torrefaction Efficiency

- What other industries benefit from vertical fluidized bed tube furnaces? Boost Efficiency in High-Tech and Heavy Sectors

- What features contribute to the flexibility and diversity of a vertical tube furnace? Tailor Your Thermal Process

- What essential experimental conditions does a laboratory horizontal tube furnace provide for wood chip pyrolysis?

- What are the technical requirements for a fixed-bed quartz reactor? Ensure Pure Data in Dry Reforming of Methane

- What are the key features of high temperature tube furnaces? Unlock Precision for Material Science

- What technical advantages does a three-zone tube furnace offer for CrSb? Master Precision Crystal Engineering

- What is the function of a vacuum tube furnace in NbC-Cr7C3@graphene/Fe synthesis? Expert Guide to In-Situ Synthesis