At their core, high-temperature tube furnaces are defined by their capacity to reach extreme temperatures (often up to 1800°C), their precise control over the heating profile, and their ability to maintain a specific internal atmosphere. These three capabilities—heat, control, and atmosphere—work in concert to create a highly repeatable environment for processing advanced materials.

While high heat is the most obvious characteristic, the true value of a modern tube furnace lies in its ability to create a stable, uniform, and precisely controlled micro-environment. This transforms it from a simple oven into an indispensable instrument for material science, chemistry, and engineering.

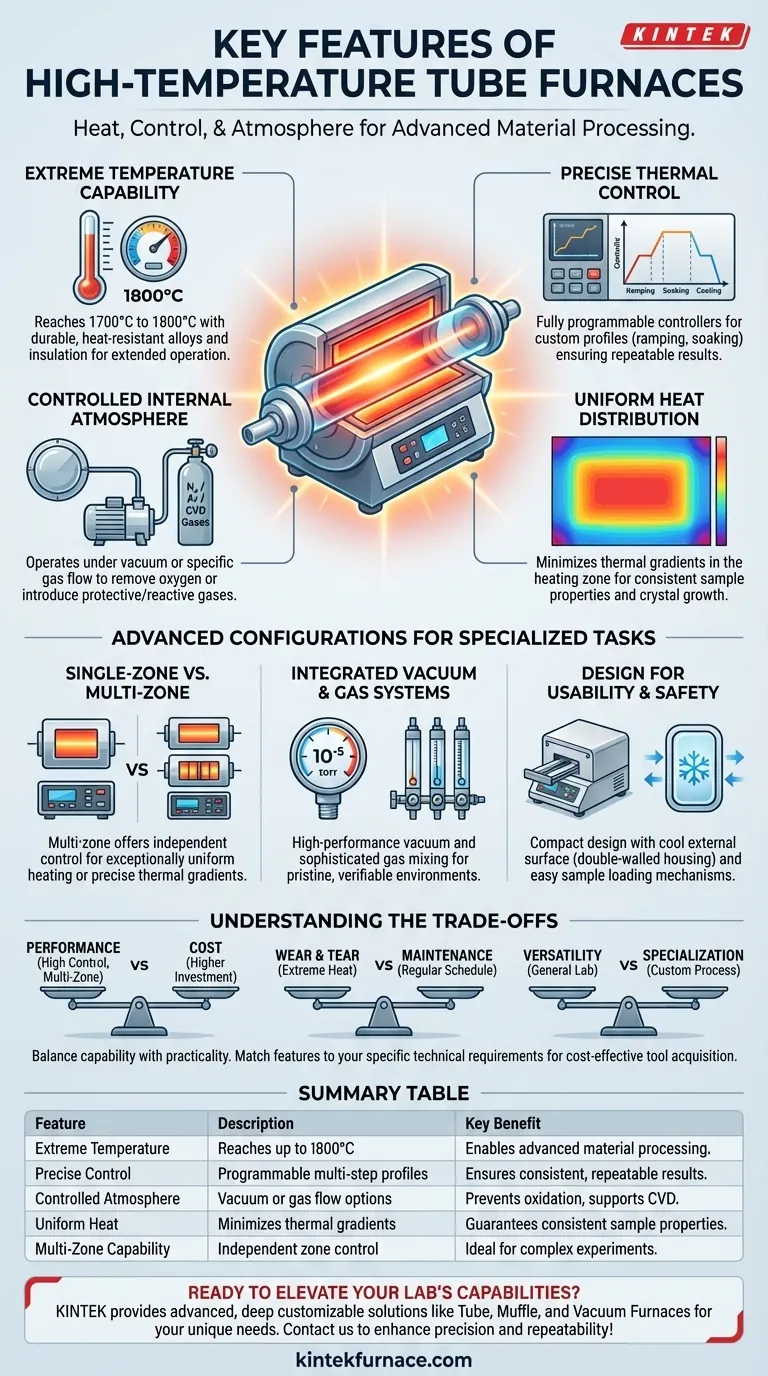

The Core Pillars of a Tube Furnace

Every feature of a tube furnace is designed to deliver control and repeatability for sensitive thermal processes. These capabilities are the foundation of its utility in both research and production.

Extreme Temperature Capability

High-temperature tube furnaces are engineered to operate at temperatures that would compromise standard equipment, with maximums often reaching 1700°C to 1800°C.

This performance is achieved through durable construction using heat-resistant alloys and specialized insulation. The design ensures the furnace can not only reach but also sustain these temperatures for extended periods.

Precise Thermal Control

Modern furnaces use fully programmable digital controllers. These allow operators to design multi-step thermal profiles that include specific heating rates (ramping), hold times at target temperatures (soaking), and controlled cooling.

This level of precision is critical for processes like annealing and sintering, where the thermal history of the material directly dictates its final properties. High accuracy ensures that results are consistent and repeatable.

A Controlled Internal Atmosphere

A key feature is the ability to operate under vacuum or with a specific gas flow. Sealed end caps and vacuum-rated components allow users to evacuate the process tube to remove oxygen and other reactive gases.

Subsequently, inert gases like nitrogen or argon can be introduced to create a protective environment, preventing oxidation of the sample. For processes like Chemical Vapor Deposition (CVD), specific reactive gases can be precisely mixed and introduced.

Uniform Heat Distribution

Achieving a uniform temperature zone across the length of the sample is non-negotiable for quality results. Furnaces are designed to minimize hot spots and thermal gradients within the central heating zone.

This uniformity ensures that the entire sample undergoes the exact same thermal process, which is essential for consistent material properties, crystal growth, and coating deposition.

Advanced Configurations for Specialized Tasks

Beyond the core features, many furnaces can be configured with specialized options that tailor them to very specific applications, moving them from a general-purpose tool to a highly optimized instrument.

Single-Zone vs. Multi-Zone Furnaces

While a single-zone furnace has one set of heating elements and one controller, more advanced models feature two or more heating zones.

Each zone in a multi-zone furnace can be controlled independently. This can be used to create an exceptionally uniform and stable hot zone in the center or to intentionally establish a precise temperature gradient along the tube for transport experiments.

Integrated Vacuum and Gas Systems

For applications demanding pristine environments, furnaces can be equipped with high-performance vacuum systems capable of reaching pressures as low as 10⁻⁵ torr.

They can also incorporate sophisticated gas mixing systems and data logging software, giving the user complete control and a verifiable record of the atmospheric conditions during the entire process.

Design for Usability and Safety

Many modern furnaces feature a compact, bench-top design. Some are built with a sliding or hinged mechanism that allows the tube to be moved out of the heating chamber for rapid cooling and easier loading or unloading of samples.

Safety is also paramount. A double-walled housing with internal air cooling keeps the external surface temperature low, even when the furnace is operating at maximum heat, protecting operators from burns.

Understanding the Trade-offs

Selecting a tube furnace requires balancing capability with practicality. More advanced features introduce complexity and cost that may not be necessary for every application.

Performance vs. Cost

A multi-zone furnace with integrated high-vacuum and gas mixing systems offers ultimate control but comes at a significantly higher initial cost and requires more expertise to operate effectively. A simpler single-zone model is far more cost-effective for basic thermal treatment.

The Inevitability of Wear and Tear

Operating at extreme temperatures inherently causes wear on heating elements, insulation, and process tubes. High operational costs and a consistent maintenance schedule are unavoidable realities of using this type of equipment.

Versatility vs. Specialization

A highly customized furnace built for a specific CVD process may be the best tool for that one job, but it might lack the flexibility needed for general-purpose lab work. You must decide whether you need a specialist or a generalist tool.

Making the Right Choice for Your Application

Your choice must be driven by the specific demands of your process. Carefully matching the furnace's features to your technical requirements ensures you acquire a tool that is both capable and cost-effective.

- If your primary focus is basic annealing or sintering: A robust single-zone furnace with simple gas flow control is often sufficient and provides the best value.

- If your primary focus is advanced material growth (e.g., CVD or nanoparticle synthesis): A multi-zone furnace with integrated high-vacuum and precise gas mixing capabilities is likely essential for achieving high-quality, repeatable results.

- If your primary focus is process development or research: A versatile, configurable furnace with software for data logging will provide the flexibility needed to explore different processing parameters.

By understanding how each feature serves a specific function, you can confidently select a furnace that will be a productive and reliable asset for your work.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Extreme Temperature | Reaches up to 1800°C with durable construction | Enables processing of advanced materials |

| Precise Thermal Control | Programmable digital controllers for multi-step profiles | Ensures consistent, repeatable results |

| Controlled Atmosphere | Vacuum or gas flow options (e.g., nitrogen, argon) | Prevents oxidation and supports CVD processes |

| Uniform Heat Distribution | Minimizes thermal gradients in the heating zone | Guarantees consistent sample properties |

| Multi-Zone Capability | Independent control for uniform or gradient heating | Ideal for complex experiments and transport studies |

Ready to elevate your lab's capabilities with a high-temperature tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored for material science, chemistry, and engineering labs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how our furnaces can enhance precision, repeatability, and efficiency in your thermal processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision