The vacuum reaction chamber acts as the fundamental control variable in the Plasma Enhanced Chemical Vapor Deposition (PECVD) process. It establishes a high-vacuum environment that eliminates atmospheric interference, allowing precursor gases to undergo precise, plasma-excited chemical reactions required to modify titanium alloys.

The vacuum environment is not merely about removing air; it is the prerequisite for determining the structural integrity of the final coating. By strictly controlling the atmosphere, the chamber ensures that coatings like Titanium Nitride (TiN) achieve the high purity, density, and uniformity necessary to serve as an effective physical barrier.

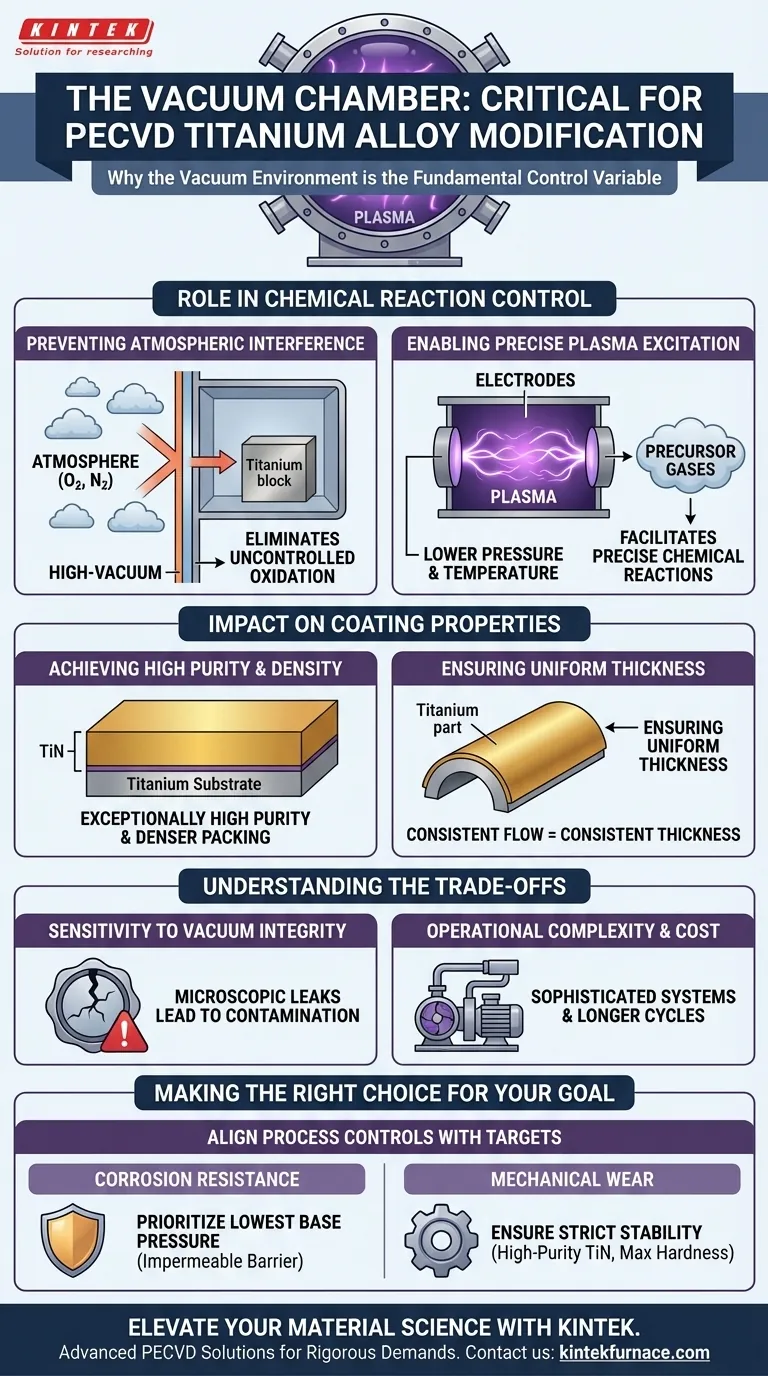

The Role of the Vacuum in Chemical Reaction Control

Preventing Atmospheric Interference

The most immediate function of the vacuum chamber is the exclusion of ambient air. Titanium alloys are highly reactive to oxygen and nitrogen found in the atmosphere.

By maintaining a high-vacuum state, the system prevents uncontrolled oxidation or contamination during the deposition process. This ensures that the surface modification is driven solely by the intended precursor gases, not by random atmospheric variables.

Enabling Precise Plasma Excitation

PECVD relies on plasma to excite precursor gases into a reactive state at lower temperatures.

The vacuum chamber lowers the pressure to a specific range where this plasma excitation can occur efficiently. This controlled low-pressure environment facilitates precise chemical reactions, allowing the precursor materials to bond effectively with the titanium substrate.

Impact on Coating Properties

Achieving High Purity and Density

The quality of the vacuum directly correlates to the quality of the material deposited on the alloy.

Because the chamber removes volatile impurities and adsorbed gases, the resulting coatings—such as Titanium Nitride (TiN)—possess exceptionally high purity. Furthermore, the absence of interfering molecules allows for a denser packing of atoms, creating a robust physical shield.

Ensuring Uniform Thickness

A stable vacuum environment promotes the consistent flow and distribution of reactive gases.

This stability ensures that the coating grows at a uniform rate across the geometry of the titanium alloy. The result is a layer with consistent thickness, avoiding weak points or structural irregularities that could compromise protection.

Understanding the Trade-offs

Sensitivity to Vacuum Integrity

The reliance on a high-vacuum environment introduces a significant point of failure. Even microscopic leaks or slight fluctuations in pressure can introduce oxygen, leading to immediate contamination.

If the vacuum integrity is compromised, the coating may suffer from poor adhesion, porosity, or the formation of unwanted oxides rather than the intended nitrides.

Operational Complexity and Cost

Maintaing a high-vacuum reaction chamber adds layers of complexity to the manufacturing process.

It requires sophisticated pumping systems, rigorous seal maintenance, and longer cycle times to achieve the necessary base pressure before deposition can begin. This increases both the capital equipment costs and the operational overhead compared to non-vacuum coating methods.

Making the Right Choice for Your Goal

To maximize the benefits of PECVD for titanium alloys, you must align your process controls with your specific performance targets.

- If your primary focus is corrosion resistance: Prioritize the lowest possible base pressure to maximize coating density, creating an impermeable physical barrier against environmental attack.

- If your primary focus is mechanical wear: Ensure strict stability of the vacuum level during plasma excitation to guarantee high-purity TiN formation for maximum surface hardness.

The vacuum chamber is not just a vessel; it is the active environment that defines the purity and performance limit of your titanium alloy modification.

Summary Table:

| Feature | Role in PECVD Process | Impact on Titanium Alloy |

|---|---|---|

| Atmospheric Exclusion | Removes oxygen and nitrogen | Prevents uncontrolled oxidation and contamination |

| Plasma Excitation | Facilitates gas reactivity at low pressures | Enables precise chemical bonding at lower temperatures |

| Purity Control | Eliminates volatile impurities | Ensures high-density, robust Titanium Nitride (TiN) layers |

| Gas Distribution | Maintains stable reactive gas flow | Achieves uniform coating thickness across complex geometries |

| Vacuum Integrity | Strict pressure regulation | Prevents porosity and ensures strong coating adhesion |

Elevate Your Material Science with KINTEK

Unlock the full potential of your titanium alloy modifications with KINTEK’s advanced PECVD solutions. Backed by expert R&D and world-class manufacturing, we provide high-performance Vacuum, CVD, and Muffle systems designed for the rigorous demands of plasma-enhanced deposition.

Whether you require precise corrosion resistance or maximum surface hardness, our customizable lab high-temp furnaces offer the vacuum integrity and stability your research deserves. Contact our technical specialists today to discuss how KINTEK can optimize your lab’s thermal processing efficiency.

Visual Guide

References

- Qin Rao, Shunli Zheng. Research Progress of the Coatings Fabricated onto Titanium and/or Titanium Alloy Surfaces in Biomaterials for Medical Applications for Anticorrosive Applications. DOI: 10.3390/coatings15050599

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What types of coatings are applied using PECVD in mechanical engineering? Enhance Wear and Corrosion Resistance

- What are the advantages of Plasma-Enhanced Chemical Vapor Deposition (PECVD)? Achieve Superior Thin Films at Lower Temperatures

- What types of thin films are commonly associated with PECVD processes? Discover Low-Temperature Deposition Solutions

- What were the initial configurations of Plasma Enhanced Chemical Vapor Deposition (PECVD) systems? Explore Early Semiconductor Innovations

- What role does PECVD play in creating optical coatings? Achieve Precision Thin Films for Enhanced Optics

- What is the primary role of PECVD in a-SiC:H film preparation? Low-Temp Precision for Advanced Thin Films

- How can the properties of PECVD films be altered? Master Thin-Film Engineering with Precision Control

- What is the purpose of PECVD? Enable Low-Temperature, High-Quality Thin Film Deposition