In short, the properties of films created by Plasma-Enhanced Chemical Vapor Deposition (PECVD) are deliberately altered by precisely adjusting the process parameters within the deposition chamber. Key variables include the radio frequency (RF) power and frequency, the flow rates of precursor gases, and the substrate temperature, all of which directly influence the final film's chemical, electrical, and mechanical characteristics.

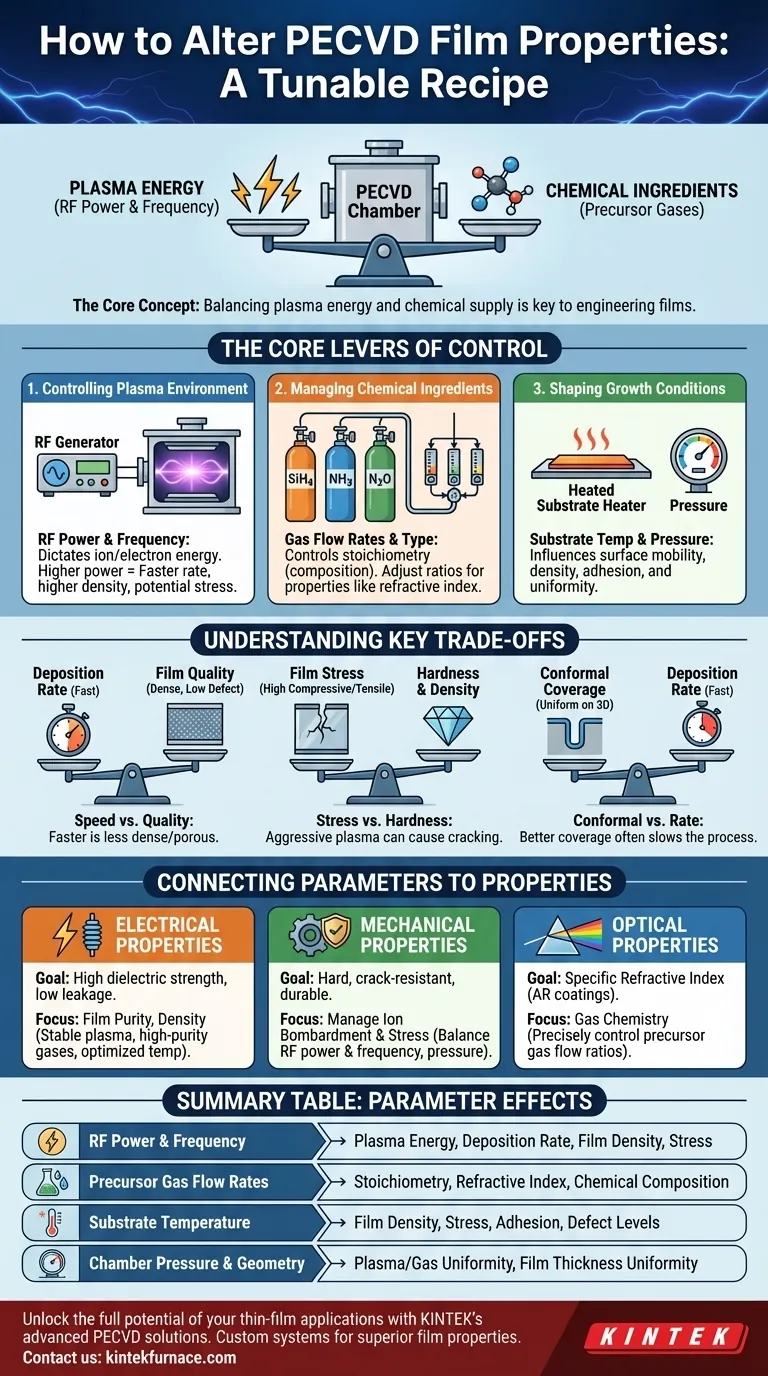

At its core, PECVD is a highly tunable "recipe" for thin films. Understanding that you are balancing two main factors—the energy of the plasma and the supply of chemical ingredients—is the key to engineering a film with the exact properties your application demands.

The Core Levers of PECVD Control

To effectively alter a film's properties, you must understand the levers at your disposal. These parameters control the plasma environment and the chemical reactions occurring on the substrate surface.

Controlling the Plasma Environment

The plasma is the engine of the PECVD process. It breaks down stable precursor gases into reactive species. Controlling its energy and density is fundamental.

Parameters like RF frequency and power directly dictate the energy of the ions and electrons in the plasma. Higher power generally increases deposition rate and film density but can also introduce stress into the film.

Managing the Chemical Ingredients

The final composition of your film is determined by the ingredients you supply.

The flow rate and type of precursor gases control the film's stoichiometry—the precise ratio of different elements. For example, when depositing silicon oxynitride (SiOxNy), adjusting the ratio of silane, oxygen, and nitrogen precursors allows you to finely tune the film's refractive index.

Shaping the Growth Conditions

The environment where the film grows is just as critical as the plasma and precursors.

Substrate temperature influences the mobility of atoms on the surface, affecting film density, stress, and adhesion. While PECVD allows for lower temperatures than traditional CVD, this parameter is still a powerful tool for tuning film quality.

The chamber pressure and reactor geometry, including electrode spacing and gas inlet configuration, impact the uniformity of both the plasma and the gas flow, which in turn determines the film's thickness uniformity across the substrate.

Understanding the Key Trade-offs

Adjusting one parameter often has consequences for other film properties. Recognizing these trade-offs is a hallmark of expert process control.

Deposition Rate vs. Film Quality

Increasing RF power or precursor flow rates can speed up deposition, which is desirable for manufacturing throughput. However, depositing too quickly can lead to a less dense, more porous film with inferior electrical or mechanical properties and higher defect counts.

Film Stress vs. Hardness and Density

Aggressive plasma conditions, often used to create very hard and dense films, can impart significant compressive or tensile stress. Excessive stress can cause the film to crack or delaminate from the substrate, compromising the device. Finding a balance is critical for creating durable, reliable layers.

Conformal Coverage vs. Deposition Rate

Achieving a conformal film that uniformly coats complex, three-dimensional structures often requires specific process conditions, such as higher pressure or pulsed plasma. These conditions may slow the overall deposition rate but are essential for applications like filling deep trenches in microelectronics without creating voids.

Connecting Parameters to Final Film Properties

Your goal dictates which parameters you should focus on.

For Electrical Properties

To achieve high dielectric strength and low leakage current for insulating layers, your focus should be on film purity and density. This requires stable plasma, high-purity precursor gases, and an optimized temperature to minimize voids and contaminants.

For Mechanical Properties

To create a hard, crack-resistant film for a hard mask or passivation layer, you must carefully manage ion bombardment and film stress. This involves balancing RF power and frequency to achieve high density without introducing excessive internal stress.

For Optical Properties

To dial in a specific refractive index for an anti-reflection coating or optical filter, your primary lever is the gas chemistry. Precisely controlling the flow rates of your precursor gases directly determines the film's elemental composition and, therefore, its optical behavior.

How to Apply This to Your Goal

Before starting a deposition, clarify your primary objective for the film.

- If your primary focus is creating a superior electrical insulator: Prioritize precursor purity, plasma stability, and finding the optimal temperature to create a dense, defect-free film.

- If your primary focus is tuning optical performance: Concentrate on precisely controlling the precursor gas flow ratios to achieve the target chemical composition and refractive index.

- If your primary focus is mechanical durability for a protective layer: Methodically balance RF power and pressure to maximize film density while keeping internal stress low enough to prevent cracking.

Mastering these parameters transforms PECVD from a simple deposition technique into a precise engineering tool for creating custom thin-film materials.

Summary Table:

| Parameter | Effect on Film Properties |

|---|---|

| RF Power & Frequency | Controls plasma energy, deposition rate, film density, and stress |

| Precursor Gas Flow Rates | Determines stoichiometry, refractive index, and chemical composition |

| Substrate Temperature | Influences film density, stress, adhesion, and defect levels |

| Chamber Pressure & Geometry | Affects plasma and gas uniformity, leading to consistent film thickness |

Unlock the full potential of your thin-film applications with KINTEK's advanced PECVD solutions!

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace systems, including our specialized CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, helping you achieve superior film properties with optimized process control.

Ready to enhance your research or production? Contact us today to discuss how our expertise can benefit your specific goals!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What are the applications of PECVD? Unlock Low-Temperature Thin-Film Deposition

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process