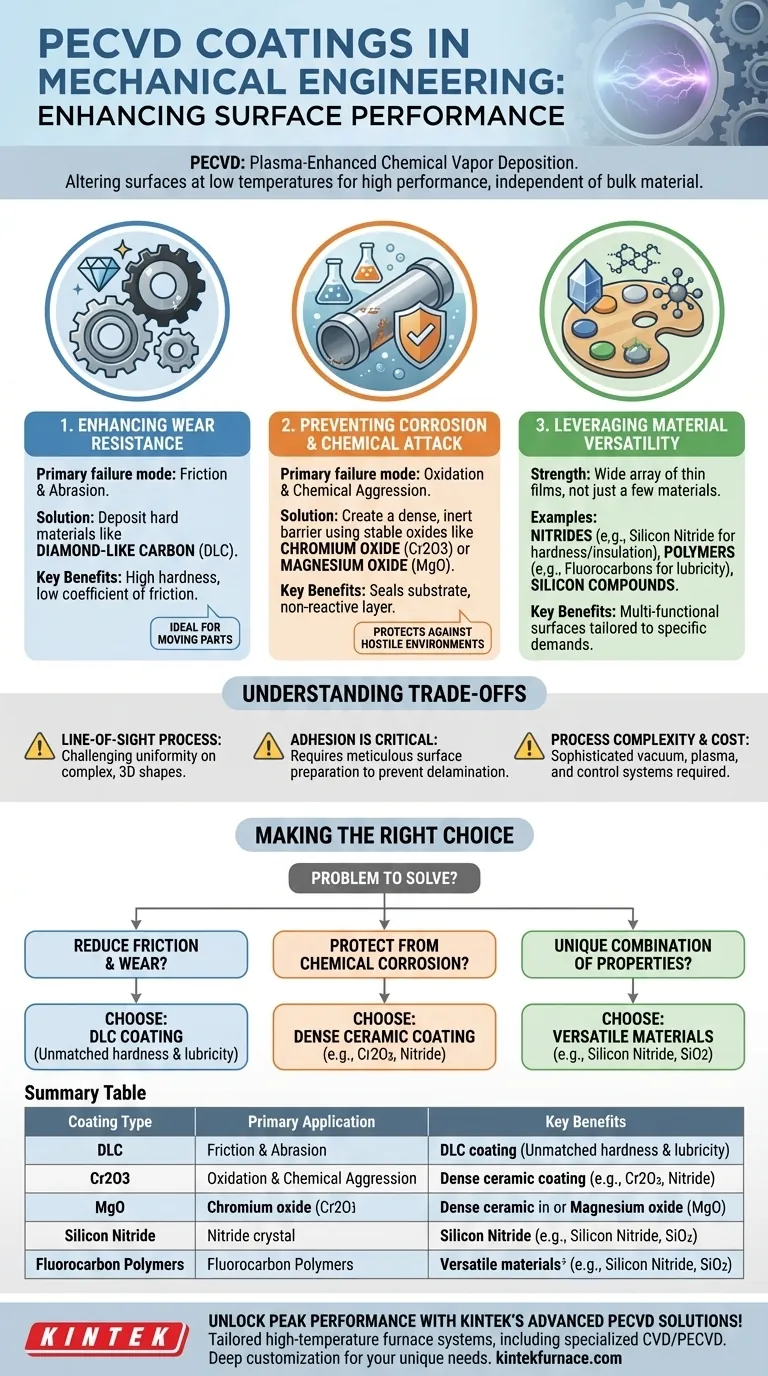

In mechanical engineering, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is primarily used to apply advanced coatings that enhance a component's surface properties. The most common applications involve depositing wear-resistant films like diamond-like carbon (DLC) and corrosion-resistant layers such as chromium oxide (Cr2O3) or magnesium oxide (MgO).

The true value of PECVD lies not in a single type of coating, but in its versatility. It allows engineers to precisely deposit a wide range of materials at low temperatures, fundamentally altering a component's surface for high performance without compromising the integrity of the underlying bulk material.

Why PECVD is a Key Tool for Mechanical Surfaces

The core challenge in mechanical design is often a conflict between the properties needed for the bulk of a component (e.g., toughness, strength) and the properties needed at its surface (e.g., hardness, chemical inertness). PECVD directly solves this by adding a functional thin film.

Enhancing Wear Resistance

For components subjected to friction and abrasion, wear is the primary failure mode. PECVD provides a powerful solution by depositing exceptionally hard materials.

The most prominent example is diamond-like carbon (DLC). These films possess a unique combination of high hardness and a low coefficient of friction, making them ideal for protecting moving parts.

Preventing Corrosion and Chemical Attack

Mechanical components often operate in environments that are chemically aggressive or prone to oxidation. PECVD can create a protective, chemically inert barrier on the component's surface.

By depositing stable compounds like chromium oxide (Cr2O3) or magnesium oxide (MgO), a dense, non-reactive layer is formed. This film effectively seals the substrate material from the hostile environment.

Leveraging a Broad Material Palette

While DLC and specific oxides are common, the flexibility of PECVD is its greatest strength. The process is not limited to just a few materials.

It can deposit a wide array of thin films, including nitrides (like silicon nitride, also very hard), polymers (such as fluorocarbons for extreme lubricity), and various silicon compounds. This versatility allows for the creation of multi-functional surfaces tailored to highly specific operational demands.

Understanding the Trade-offs

While powerful, PECVD is not a universal solution. Acknowledging its limitations is critical for successful implementation.

Coating Uniformity on Complex Geometries

PECVD is fundamentally a line-of-sight process. This can make it challenging to achieve a perfectly uniform coating thickness on parts with complex, three-dimensional shapes, internal channels, or sharp corners.

Critical Importance of Adhesion

The performance of any coating is entirely dependent on its adhesion to the substrate. The success of a PECVD coating relies heavily on meticulous surface preparation to ensure a strong bond. Failure to do so can result in the coating delaminating or flaking off under stress.

Process Complexity and Cost

PECVD requires sophisticated vacuum chambers, precise gas flow control, and high-frequency power supplies to generate the plasma. This makes it a more complex and often more expensive process compared to simpler surface treatments like painting or electroplating.

Making the Right Choice for Your Goal

Selecting the correct coating strategy depends entirely on the problem you need to solve.

- If your primary focus is reducing friction and wear: Your best option is a Diamond-Like Carbon (DLC) coating due to its unmatched hardness and lubricity.

- If your primary focus is protection from chemical corrosion: You should specify a dense, inert ceramic coating like a stable oxide (Cr2O3) or nitride.

- If your primary focus is a unique combination of properties (e.g., hardness and electrical insulation): Leverage PECVD's versatility to explore materials like silicon nitride or silicon dioxide to meet your specific multi-functional requirement.

Ultimately, PECVD empowers you to engineer the surface of a component independently of its bulk, unlocking new levels of performance and durability.

Summary Table:

| Coating Type | Primary Application | Key Benefits |

|---|---|---|

| Diamond-Like Carbon (DLC) | Wear Resistance | High hardness, low friction |

| Chromium Oxide (Cr2O3) | Corrosion Resistance | Dense, chemically inert barrier |

| Magnesium Oxide (MgO) | Corrosion Resistance | Protective, non-reactive layer |

| Silicon Nitride | Multi-functional Surfaces | Hardness, electrical insulation |

| Fluorocarbon Polymers | Lubricity | Extreme lubricity for moving parts |

Unlock peak performance for your mechanical components with KINTEK's advanced PECVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including our specialized CVD/PECVD systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering coatings that enhance wear resistance, prevent corrosion, and extend component lifespan. Contact us today to discuss how we can optimize your surface engineering processes!

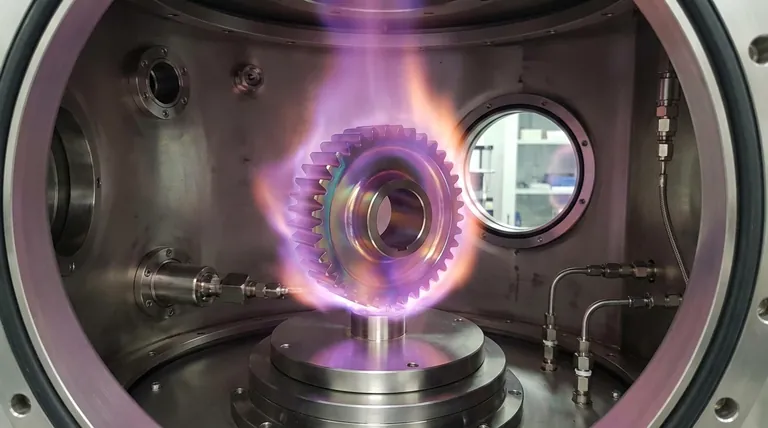

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition