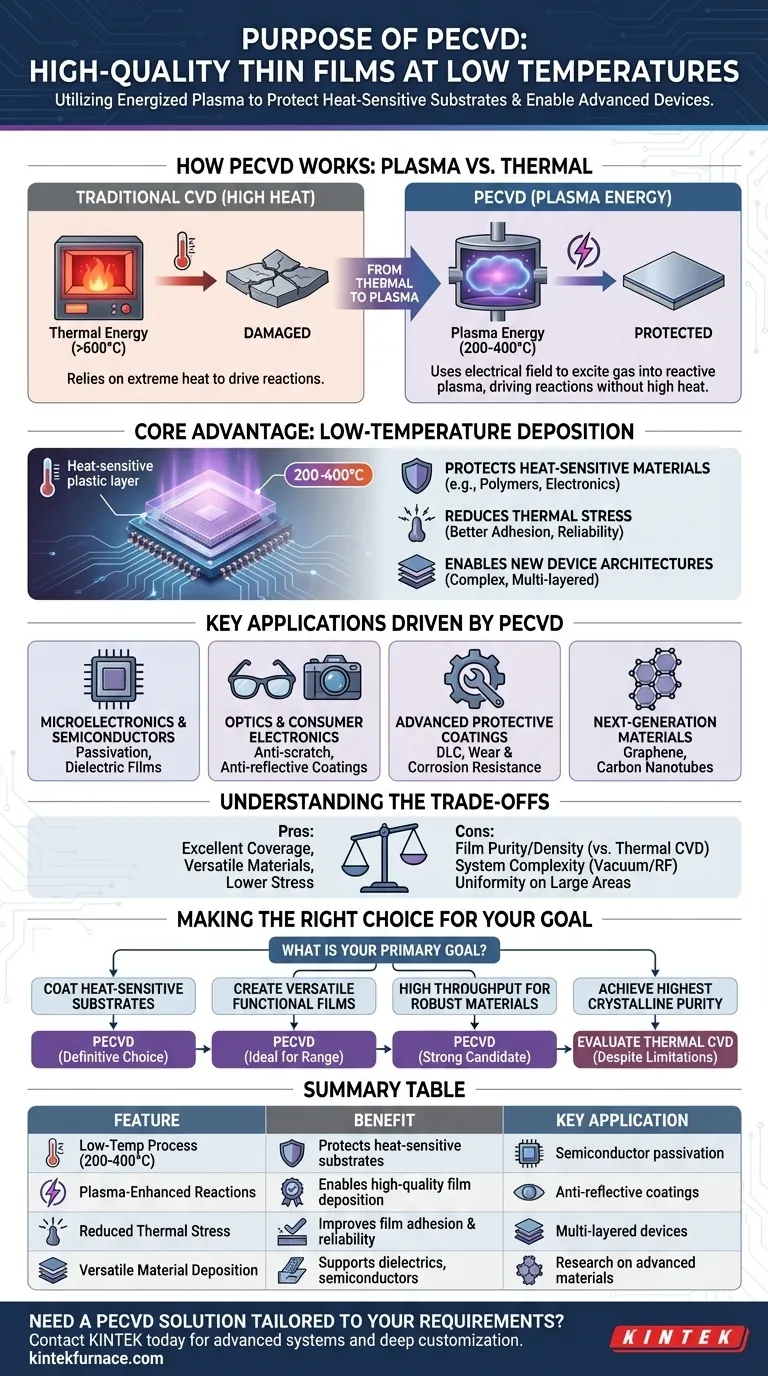

The primary purpose of Plasma-Enhanced Chemical Vapor Deposition (PECVD) is to deposit high-quality, durable thin films onto a substrate at significantly lower temperatures than traditional methods. It uses an energized plasma to drive the chemical reactions needed to form the film, making it an essential process for manufacturing modern electronics, optics, and advanced materials that cannot tolerate high heat.

PECVD overcomes the high-temperature limitations of conventional Chemical Vapor Deposition (CVD). By using plasma to energize precursor gases, it enables the creation of high-performance thin films on materials that would otherwise be damaged or destroyed by heat.

How PECVD Works: The Role of Plasma

From Thermal Energy to Plasma Energy

Traditional Chemical Vapor Deposition (CVD) relies on very high temperatures, often many hundreds of degrees Celsius, to provide the thermal energy needed to break down precursor gases and deposit a film.

PECVD fundamentally changes this equation. Instead of heat, it uses an electrical field to excite a gas into a plasma, an energetic state of matter containing ions, electrons, and free radicals.

Driving Reactions Without Extreme Heat

This plasma provides the energy required to initiate the chemical reactions. The highly reactive species in the plasma decompose the precursor gases and deposit the desired material onto the substrate surface, molecule by molecule.

Because the energy comes from the plasma rather than thermal agitation, the entire process can run at much lower temperatures, often between 200-400°C, and sometimes even lower.

The Core Advantage: Low-Temperature Deposition

Protecting Heat-Sensitive Substrates

The single most important benefit of PECVD is its ability to coat materials that cannot survive the high temperatures of conventional CVD.

This includes polymers, plastics, and fully assembled microelectronic devices with pre-existing sensitive components. Without PECVD, coating these materials would be impossible.

Reducing Material Stress

High temperatures create thermal stress in both the deposited film and the underlying substrate as they cool. This stress can lead to cracking, poor adhesion, and device failure.

By operating at lower temperatures, PECVD minimizes thermal stress, resulting in more durable and reliable films with excellent adhesion.

Enabling New Device Architectures

The ability to deposit high-quality dielectrics, semiconductors, and protective layers on a wide variety of substrates opens up new possibilities for engineers. It allows for the creation of complex, multi-layered devices that would otherwise be unmanufacturable.

Key Applications Driven by PECVD's Capabilities

Microelectronics and Semiconductors

PECVD is a cornerstone of the semiconductor industry. It is used to deposit critical layers such as passivation films that protect the chip surface, and insulating (dielectric) films that separate conductive layers.

Optics and Consumer Electronics

The hard, clear anti-scratch and anti-reflective coatings on eyeglasses, camera lenses, and smartphone screens are often created using PECVD. Its ability to coat surfaces evenly makes it ideal for these applications.

Advanced Protective Coatings

PECVD is used to deposit ultra-hard diamond-like carbon (DLC) films. These coatings provide exceptional wear and corrosion resistance for tools, automotive parts, and medical implants.

Next-Generation Materials

The process is also employed in cutting-edge research and development to synthesize advanced materials like graphene, carbon nanotubes, and even polycrystalline diamond films.

Understanding the Trade-offs

Film Purity and Density

While PECVD films are high-quality, the plasma environment can sometimes introduce hydrogen or other impurities into the film. For applications requiring the absolute highest purity or density, a higher-temperature thermal CVD process may still be necessary.

System Complexity

PECVD systems require vacuum chambers, gas handling, and radio-frequency (RF) or microwave power sources to generate the plasma. This makes them more complex and costly than some simpler, non-vacuum deposition techniques.

Deposition Uniformity

While PECVD provides excellent coverage over complex shapes, achieving perfect film thickness uniformity across very large substrates (like large-area displays or solar panels) requires careful reactor design and process control.

Making the Right Choice for Your Goal

When deciding if PECVD is the correct process, your primary goal is the most important factor.

- If your primary focus is coating heat-sensitive substrates: PECVD is the definitive choice, as its low-temperature process prevents damage to materials like plastics or integrated electronics.

- If your primary focus is creating versatile functional films: PECVD is ideal for its ability to deposit a wide range of materials, including insulators, protective layers, and semiconductors.

- If your primary focus is high throughput for robust materials: PECVD is often faster than low-pressure CVD, making it a strong candidate for efficient production.

- If your primary focus is achieving the absolute highest crystalline purity: You should evaluate whether a higher-temperature thermal CVD process is required for your specific material, despite its limitations.

Ultimately, PECVD is the definitive tool for engineering advanced surfaces on the vast range of materials that cannot withstand the heat of conventional methods.

Summary Table:

| Feature | Benefit | Key Application |

|---|---|---|

| Low-Temperature Process (200-400°C) | Protects heat-sensitive substrates like plastics & electronics | Semiconductor passivation, coating on polymers |

| Plasma-Enhanced Reactions | Enables high-quality film deposition without extreme heat | Anti-reflective coatings on lenses, DLC coatings |

| Reduced Thermal Stress | Improves film adhesion and device reliability | Multi-layered microelectronic devices |

| Versatile Material Deposition | Supports dielectrics, semiconductors, and protective films | Research on graphene, carbon nanotubes |

Need a PECVD solution tailored to your unique requirements?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced PECVD systems and other high-temperature furnace solutions. Whether you're working in semiconductors, optics, or advanced materials research, our deep customization capabilities ensure your PECVD process meets your exact experimental and production goals.

Contact our experts today to discuss how our PECVD and CVD systems can enhance your lab's capabilities and drive your innovations forward.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection