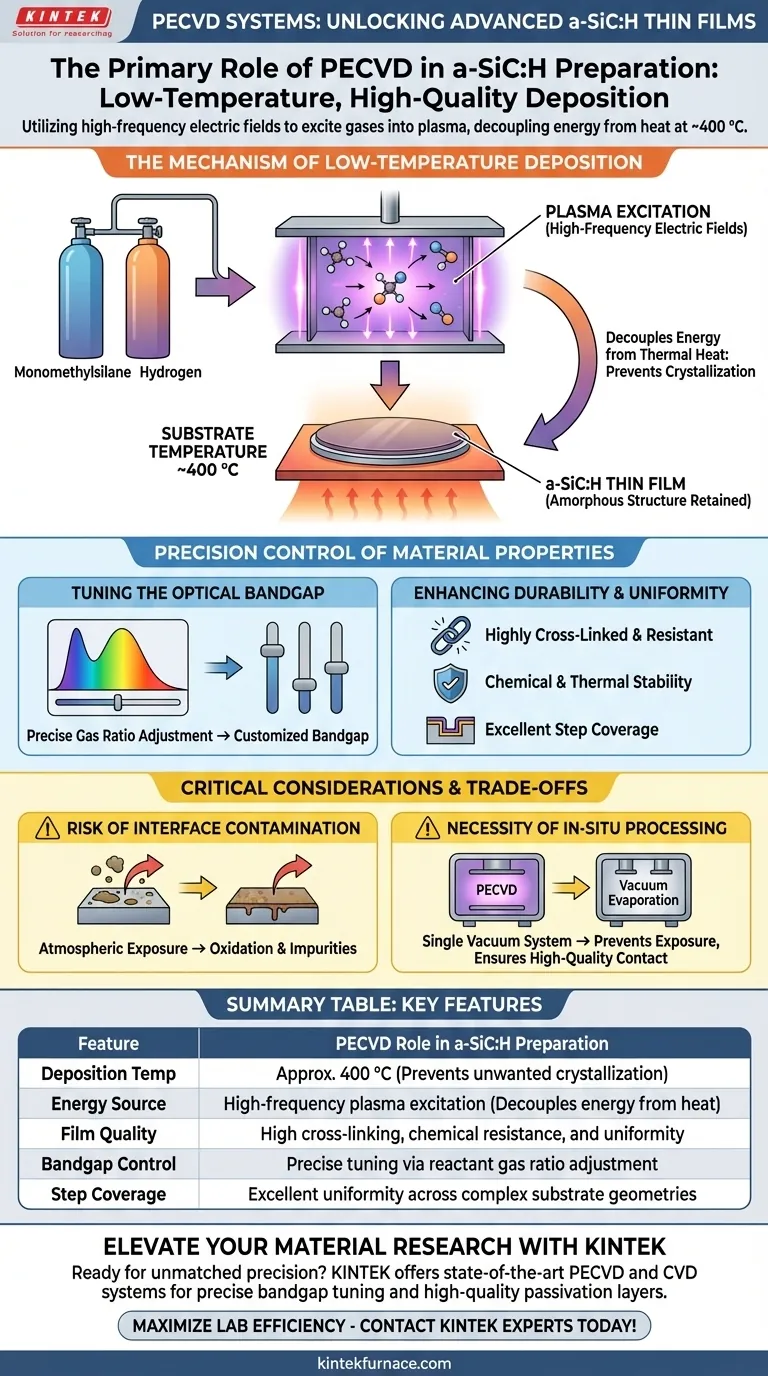

The primary role of Plasma Enhanced Chemical Vapor Deposition (PECVD) systems in the preparation of hydrogenated amorphous silicon carbide (a-SiC:H) is to facilitate chemical deposition at significantly reduced substrate temperatures. By utilizing high-frequency electric fields to excite reactant gases—specifically monomethylsilane and hydrogen—into a plasma state, PECVD allows for the creation of high-quality thin films at approximately 400 °C. This process is fundamental to fabricating wide-bandgap passivation layers that require precise compositional control without the thermal stress of traditional methods.

PECVD systems are indispensable for a-SiC:H preparation because they decouple reaction energy from thermal heat, allowing for the precise tuning of optical bandgaps and film composition while maintaining the essential amorphous structure of the material.

The Mechanism of Low-Temperature Deposition

Plasma Excitation

PECVD systems function by applying high-frequency electric fields to reactant gases. This energy excites the gas molecules, transforming them into a plasma state.

Reducing Thermal Requirements

Because the plasma provides the energy necessary to drive chemical reactions, the substrate does not need to be heated to extreme temperatures.

Maintaining Amorphous Structure

The ability to operate at approximately 400 °C is critical for a-SiC:H films. This temperature range ensures the material retains its amorphous structure rather than crystallizing, which is often required for specific optical and electronic applications.

Precision Control of Material Properties

Tuning the Optical Bandgap

The primary advantage of using PECVD for a-SiC:H is the ability to manipulate the film's composition. Operators can precisely adjust the optical bandgap of the resulting thin film, making it an ideal choice for passivation layers.

Enhancing Physical Durability

Films deposited via PECVD generally exhibit excellent physical characteristics. They are typically highly cross-linked, uniform, and resistant to both chemical and thermal changes.

Uniformity and Coverage

Beyond composition, PECVD systems are noted for providing excellent step coverage. This ensures that the film deposition is highly uniform across the substrate, which is vital for consistent device performance.

Critical Considerations and Trade-offs

The Risk of Interface Contamination

While PECVD offers excellent control, the quality of the film is highly sensitive to the deposition environment. If a sample is exposed to the atmosphere between the deposition of different layers (such as a base and a capping layer), oxidation and contamination can occur.

The Necessity of In-Situ Processing

To mitigate contamination risks, it is often necessary to integrate PECVD within a single vacuum system alongside other technologies. This "in-situ" approach prevents atmospheric exposure, ensuring high-quality physical contact between layers, such as germanium nanocrystals and the silicon carbide matrix.

Making the Right Choice for Your Goal

To maximize the effectiveness of PECVD for your specific application, consider the following:

- If your primary focus is optical performance: Prioritize the precise control of reactant gas ratios to tune the optical bandgap while maintaining the substrate at 400 °C.

- If your primary focus is multi-layer device integration: Utilize an in-situ system that combines PECVD with vacuum evaporation to prevent interface oxidation and ensure high-quality contact between layers.

Leveraging PECVD effectively requires balancing the need for low-temperature processing with the strict requirement for environmental control during deposition.

Summary Table:

| Feature | PECVD Role in a-SiC:H Preparation |

|---|---|

| Deposition Temp | Approx. 400 °C (Prevents unwanted crystallization) |

| Energy Source | High-frequency plasma excitation (Decouples energy from heat) |

| Film Quality | High cross-linking, chemical resistance, and uniformity |

| Bandgap Control | Precise tuning via reactant gas ratio adjustment |

| Step Coverage | Excellent uniformity across complex substrate geometries |

Elevate Your Material Research with KINTEK

Ready to achieve unmatched precision in your thin-film deposition? KINTEK offers state-of-the-art PECVD and CVD systems, alongside our extensive range of customizable lab furnaces. Backed by expert R&D and world-class manufacturing, we provide the tools needed for precise bandgap tuning and high-quality passivation layers.

Maximize your lab's efficiency and ensure superior device performance—Contact KINTEK experts today to find your perfect deposition solution!

Visual Guide

References

- Z. Remeš, Oleg Babčenko. Thin Hydrogenated Amorphous Silicon Carbide Layers with Embedded Ge Nanocrystals. DOI: 10.3390/nano15030176

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How is the plasma created in PECVD? Unlock Low-Temperature Thin-Film Deposition

- What safety benefits are associated with the lower operating temperature of PECVD? Enhance Lab Safety and Material Integrity

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- What are the advantages of plasma enhanced CVD? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is Plasma-Enhanced CVD (PECVD)? Unlock Low-Temp Thin Film Deposition

- What simulation tools are used to enhance PECVD processes? Discover Multi-Physics Suites for Precision

- What is in-situ process control in PECVD systems? Boost Yield with Real-Time Monitoring

- What is Inductively Coupled Plasma Chemical Vapor Deposition (ICP-CVD)? Achieve Superior Low-Temperature Thin Films